At its core, custom Polytetrafluoroethylene (PTFE) parts are used across a wide range of demanding industries, including aerospace, medical, automotive, electronics, and chemical processing. These sectors rely on custom PTFE components for critical applications like high-performance seals, biocompatible implants, electrical insulators, and non-stick, chemically-resistant surfaces where material failure is not an option.

The widespread adoption of custom PTFE is not due to a single feature, but its unique combination of properties. Industries don't just choose PTFE; they choose it to solve specific, high-stakes challenges that other materials cannot address, from resisting corrosive chemicals to ensuring patient safety.

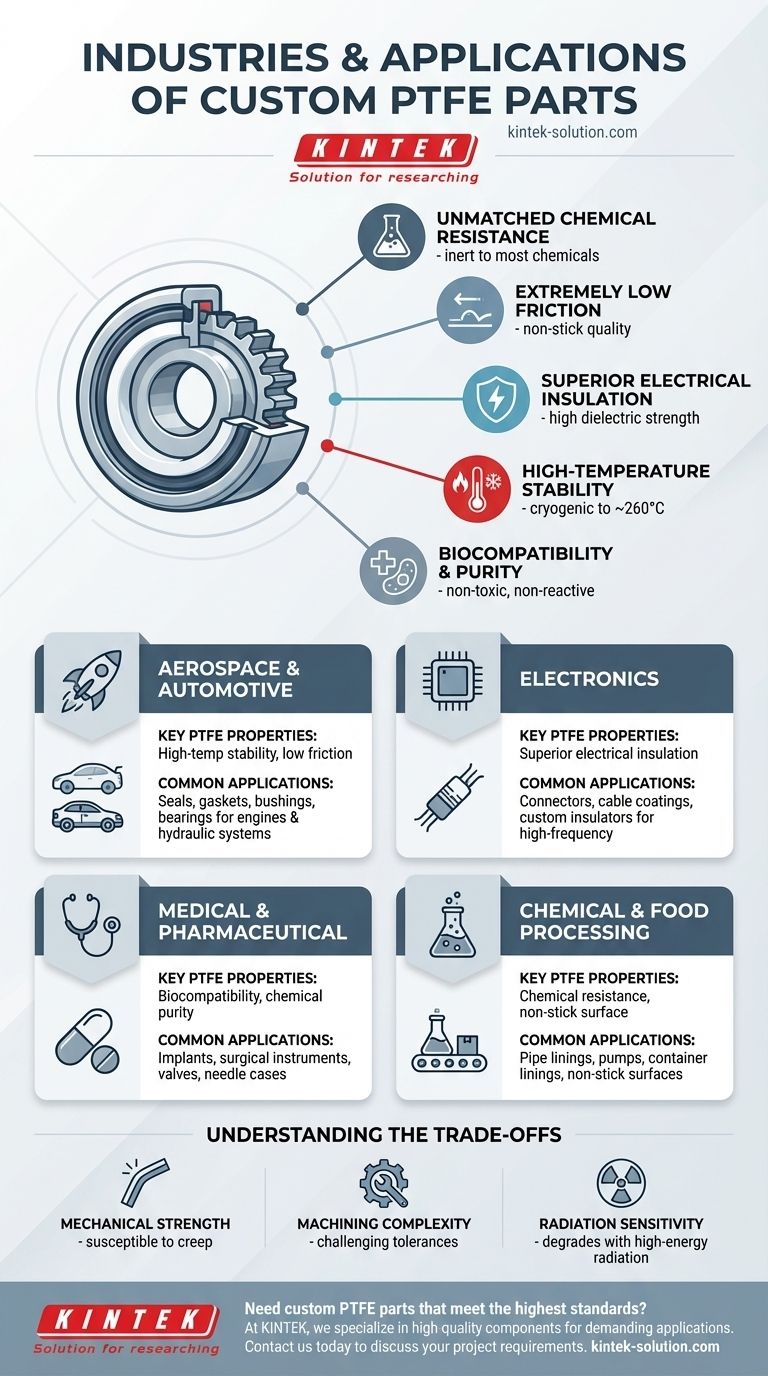

The Core Properties Driving PTFE Adoption

To understand why PTFE is so prevalent, you must first understand its fundamental characteristics. Each property solves a critical engineering problem for a specific set of industries.

Unmatched Chemical Resistance

PTFE is almost completely inert, meaning it resists degradation from nearly all industrial chemicals, acids, and solvents.

This property makes it indispensable in the chemical processing, petrochemical, and pharmaceutical industries for components like pipe linings, valves, seals, and bellows that are in constant contact with corrosive media.

Extremely Low Friction

PTFE has one of the lowest coefficients of friction of any known solid material, giving it its famous "non-stick" quality.

This is critical for applications where smooth movement and wear reduction are paramount, such as in automotive gears, aerospace anti-galling coatings, and food processing equipment like conveyor belts and blending components.

Superior Electrical Insulation

PTFE is an excellent electrical insulator with a high dielectric strength, meaning it can withstand high voltages without breaking down.

This makes it the material of choice in the electronics industry for high-frequency applications, including wire and cable insulation, connector insulators, and custom enclosures for sensitive components.

High-Temperature Stability

PTFE maintains its properties across a very wide range of temperatures, from cryogenic levels up to approximately 260°C (500°F).

This thermal stability is essential for parts used in high-temperature environments, such as engine seals and gaskets in the automotive sector or hydraulic and fuel system components in aerospace.

Biocompatibility and Purity

PTFE is non-toxic and does not react with biological tissues, making it highly biocompatible.

This is the primary reason for its extensive use in the medical and healthcare fields. It is a trusted material for surgical instruments, medical devices, and even permanent implants and prosthetics.

A Practical Look at PTFE in Key Industries

Connecting the properties to the parts reveals a clear pattern of problem-solving. Each industry leverages a specific PTFE benefit to ensure reliability and performance.

In Automotive and Aerospace

Here, the focus is on reliability under extreme conditions. Custom PTFE parts include seals, gaskets, bushings, and bearings that must withstand high temperatures and reduce friction in engines and hydraulic systems. Its use in fuel lines leverages its chemical resistance.

In Electronics

The goal is signal integrity and safety. PTFE is machined into custom insulators, connectors, and cable coatings that prevent electrical leakage, especially in high-frequency applications where other materials would fail.

In Medical and Pharmaceutical

Patient safety is the non-negotiable requirement. The biocompatibility and chemical purity of PTFE make it essential for implants, analytical instruments, needle cases, and valves that handle aggressive chemicals or come into direct contact with the human body.

In Chemical and Food Processing

These industries require parts that are both non-reactive and easy to clean. PTFE is used for container linings, pipes, pumps, and non-stick surfaces that can handle corrosive chemicals or prevent food products from adhering, ensuring both purity and operational efficiency.

Understanding the Trade-offs

No material is perfect, and objectivity requires acknowledging PTFE's limitations. Understanding these trade-offs is key to making an informed decision.

Mechanical Strength and Creep

PTFE is a relatively soft material. It can be susceptible to "creep," meaning it can deform slowly over time when under a persistent load. This must be considered in high-pressure structural designs.

Machining Complexity

While machinable, the softness of PTFE can make holding very tight tolerances for custom parts more challenging than with rigid metals or harder plastics. This requires specialized expertise.

Radiation Sensitivity

PTFE can degrade when exposed to high-energy radiation, such as gamma or electron-beam radiation. This makes it unsuitable for certain sterilization methods or applications in high-radiation environments.

Making the Right Choice for Your Application

Selecting custom PTFE is a strategic decision based on the most critical performance requirement of your project.

- If your primary focus is chemical resistance and purity: PTFE is the gold standard for components in chemical processing, pharmaceutical manufacturing, and laboratory equipment.

- If your primary focus is superior electrical insulation: Its dielectric properties make it a top-tier choice for high-frequency and high-voltage electronic applications.

- If your primary focus is low friction under thermal stress: It is an ideal solution for demanding mechanical seals, bearings, and gaskets in automotive and aerospace.

- If your primary focus is biocompatibility: It is one of the few materials proven safe and effective for medical devices, instruments, and permanent implants.

Ultimately, choosing custom PTFE is a decision to prioritize performance and reliability in environments where other materials would fail.

Summary Table:

| Industry | Key PTFE Properties | Common Applications |

|---|---|---|

| Aerospace & Automotive | High-temperature stability, low friction | Seals, gaskets, bushings, bearings |

| Electronics | Superior electrical insulation | Connectors, cable coatings, insulators |

| Medical & Pharmaceutical | Biocompatibility, chemical purity | Implants, surgical instruments, valves |

| Chemical & Food Processing | Chemical resistance, non-stick surface | Pipe linings, pumps, container linings |

Need custom PTFE parts that meet the highest standards of precision and reliability?

At KINTEK, we specialize in manufacturing high-quality PTFE components—including seals, liners, and labware—for semiconductor, medical, laboratory, and industrial applications. Whether you require prototypes or high-volume orders, our custom fabrication ensures your parts perform flawlessly in demanding environments.

Contact us today to discuss your project requirements and discover how our expertise can deliver the solution you need.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech