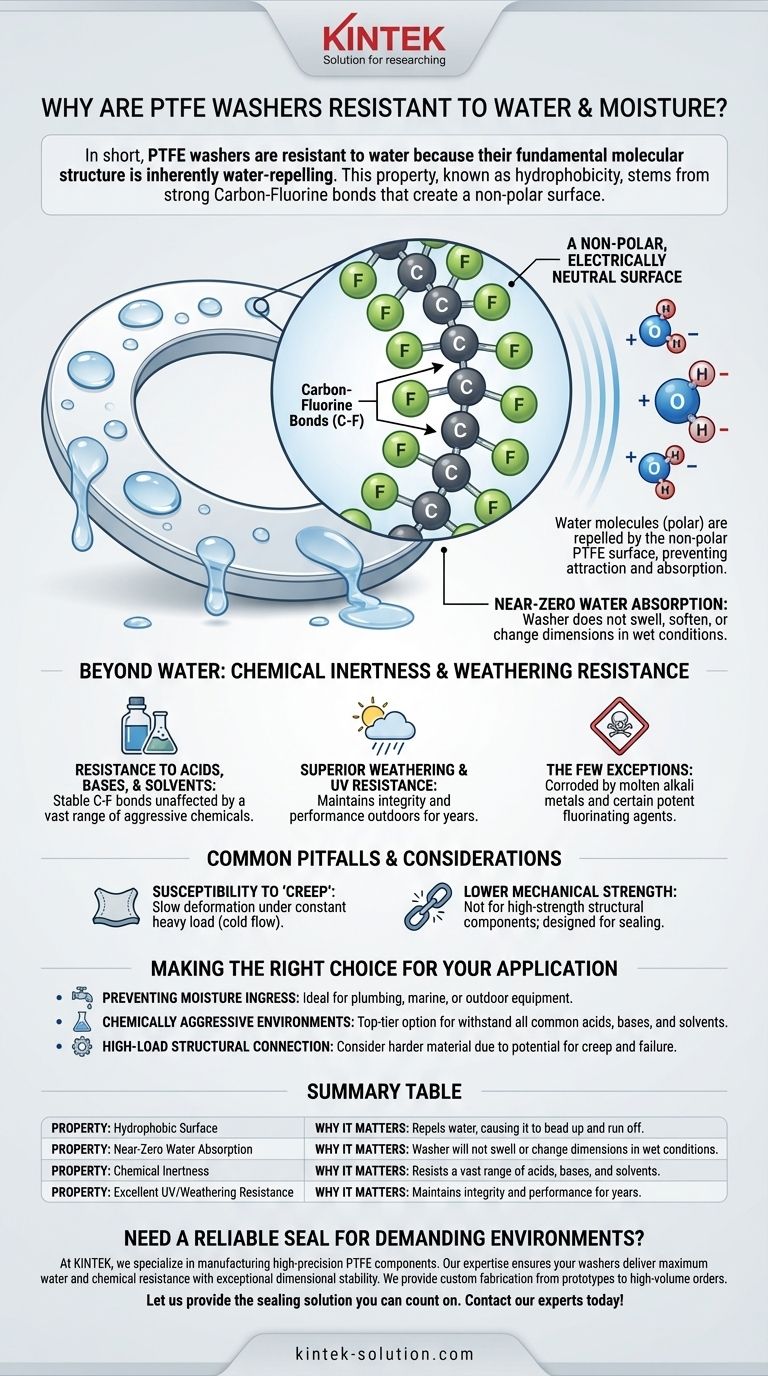

In short, PTFE washers are resistant to water because their fundamental molecular structure is inherently water-repelling. This property, known as hydrophobicity, stems from the incredibly strong and stable bonds between carbon and fluorine atoms that make up the material. These bonds create a non-polar surface that offers no attraction for polar water molecules, causing moisture to bead up and run off rather than be absorbed.

The core reason for PTFE's resistance to water, chemicals, and weathering is the same: its molecular structure is one of the most stable and non-reactive known. This chemical inertness makes it an exceptional barrier material in nearly any environment.

The Core Reason: PTFE's Molecular Structure

To understand why PTFE (polytetrafluoroethylene) excels in wet conditions, we must look at its chemistry. Its properties are not just a surface treatment; they are integral to the material itself.

The Power of Carbon-Fluorine Bonds

PTFE is a polymer, a long chain of repeating molecules. Its backbone is made of carbon atoms, but each carbon atom is completely shielded by fluorine atoms.

The bond between carbon and fluorine (C-F) is exceptionally strong and stable. This powerful bond is the primary source of PTFE's remarkable properties.

A Non-Polar, Electrically Neutral Surface

The fluorine atoms create a tight, uniform "sheath" around the carbon chain. This results in an electrically neutral and non-polar surface.

Water molecules, on the other hand, are polar—they have a slight positive charge on one side and a slight negative charge on the other. Just as two unaligned magnets might repel each other, the non-polar PTFE surface has no way to attract and hold onto polar water molecules.

Near-Zero Water Absorption

Because of this repellent nature, PTFE has one of the lowest water absorption rates of any solid material. Water simply cannot penetrate its surface or molecular structure, ensuring the washer does not swell, soften, or change its dimensions when exposed to moisture.

Beyond Water: Understanding PTFE's Chemical Inertness

The same molecular stability that repels water also makes PTFE resistant to nearly everything else. This broad resistance is what makes it so valuable in demanding industrial applications.

Resistance to Acids, Bases, and Solvents

The stable C-F bonds are not easily broken. This is why PTFE remains unaffected by exposure to a vast range of aggressive chemicals, including strong acids, bases, and organic solvents that would degrade lesser materials.

The Few Exceptions

PTFE's inertness is legendary, but it's not absolute. It can be corroded by a very small number of highly reactive substances, such as molten alkali metals and certain potent fluorinating agents like chlorine trifluoride. For the vast majority of applications, however, it is considered completely inert.

Superior Weathering and UV Resistance

The chemical stability of PTFE also translates to excellent resistance against UV radiation and general weathering. Unlike many plastics that become brittle and fail with outdoor exposure, PTFE washers maintain their integrity and performance for years.

Common Pitfalls and Considerations

While PTFE's resistance is a major advantage, it's not the right material for every single application. Understanding its limitations is key to using it effectively.

Susceptibility to "Creep"

PTFE is a relatively soft material. Under a constant, heavy load (like a tightly torqued bolt), it can slowly deform over time in a process known as "creep" or "cold flow." This can lead to a loss of sealing pressure.

Lower Mechanical Strength

Compared to metal or harder engineering plastics, PTFE has low tensile strength and abrasion resistance. It is designed to be a sealing and low-friction material, not a high-strength structural component.

Temperature Limitations

PTFE has a wide and useful service temperature range, but it is not infinite. At very high temperatures (typically above 260°C or 500°F), it will begin to soften and eventually decompose.

Making the Right Choice for Your Application

Use your understanding of PTFE's properties to select it for the right reasons.

- If your primary focus is preventing moisture ingress in plumbing, marine, or outdoor equipment: PTFE is an ideal choice due to its near-zero water absorption and excellent UV resistance.

- If your primary focus is creating a seal in a chemically aggressive environment: PTFE is a top-tier option, capable of withstanding nearly all common acids, bases, and solvents without degradation.

- If your primary focus is a high-load structural connection: You should consider a harder material, as PTFE's softness can lead to creep and failure under high mechanical stress.

Ultimately, understanding that PTFE's water resistance comes from its fundamental chemical stability allows you to deploy it with confidence in the harshest environments.

Summary Table:

| Property | Why It Matters for Water/Moisture Resistance |

|---|---|

| Hydrophobic Surface | Non-polar structure repels water, causing it to bead up and run off. |

| Near-Zero Water Absorption | Washer will not swell, soften, or change dimensions in wet conditions. |

| Chemical Inertness | Resists a vast range of acids, bases, and solvents, not just water. |

| Excellent UV/Weathering Resistance | Maintains integrity and performance for years, even outdoors. |

Need a reliable seal for demanding environments?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including seals, liners, and labware. Our expertise ensures your washers deliver maximum water and chemical resistance with exceptional dimensional stability.

We provide custom fabrication from prototypes to high-volume orders, tailored for the semiconductor, medical, laboratory, and industrial sectors.

Let us provide the sealing solution you can count on. Contact our experts today to discuss your specific requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance