At their core, Teflon-encapsulated O-rings are suitable for medical equipment because they offer an unmatched combination of chemical inertness, biocompatibility, and reliable sealing force. This unique design meets stringent safety standards like FDA and USP Class VI, making them safe for direct contact with bodily fluids and resilient against aggressive sterilization chemicals used in devices like infusion pumps, dialysis machines, and surgical tools.

The fundamental challenge in medical sealing is finding a material that is both chemically safe for the patient and mechanically effective as a seal. Teflon-encapsulated O-rings solve this by combining the flexibility of a rubber core with the complete chemical and biological inertness of a Teflon shell.

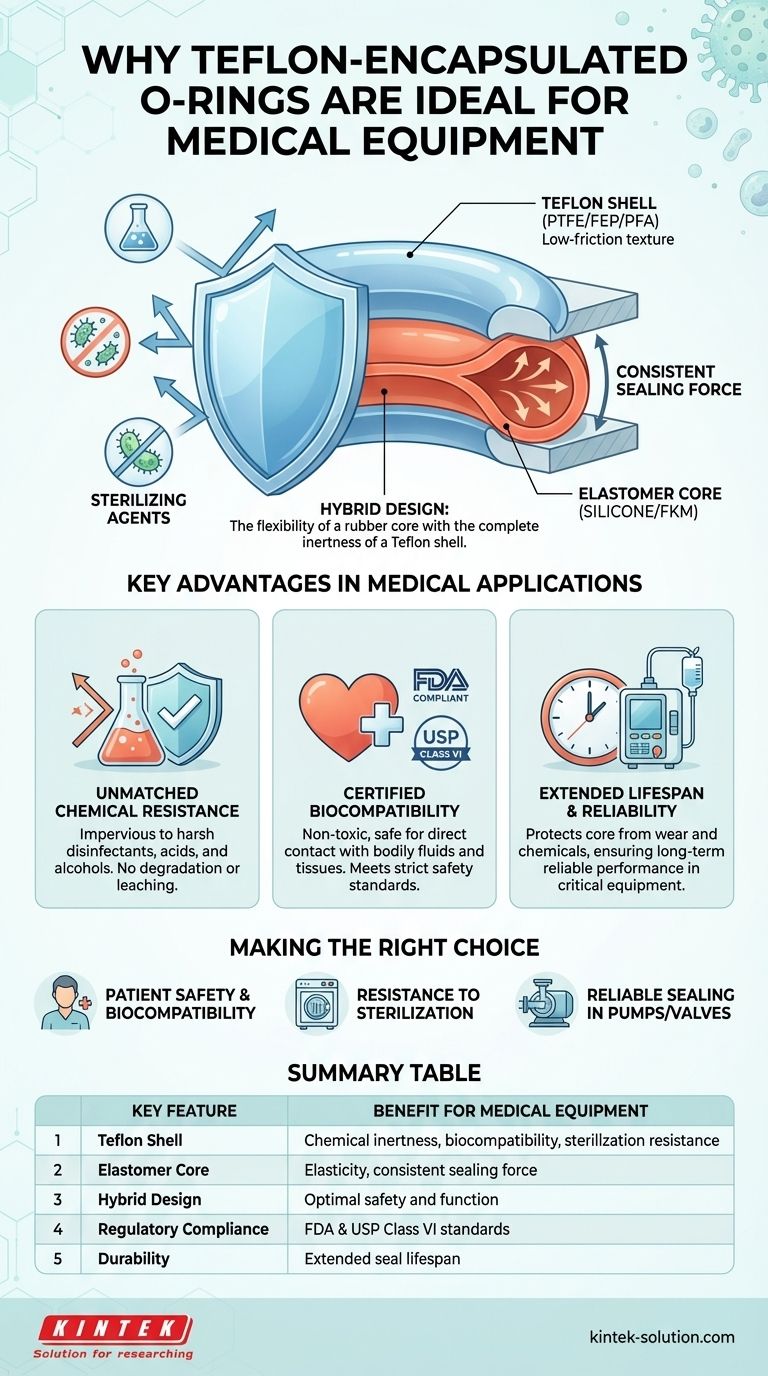

The Anatomy of a Superior Seal: Core and Shell

The effectiveness of a Teflon-encapsulated O-ring lies in its two-part construction. It isn't a single material, but a clever hybrid that leverages the strengths of two different components.

The Elastomer Core: Providing the Sealing Force

The inside of the O-ring is an elastomer, typically silicone or FKM (Viton®). This core provides the essential elasticity and resilience that allows the O-ring to compress and conform to a sealing surface, creating a tight, reliable barrier.

Without this flexible core, the seal would be rigid and ineffective.

The Teflon Shell: The Shield of Inertness

This elastomer core is completely enclosed in a seamless jacket of Teflon (PTFE, FEP, or PFA). This outer shell is the component that interacts with the medical environment, and it provides three critical properties.

First, it offers near-universal chemical resistance. Second, it is biocompatible, meaning it will not react with bodily tissues or fluids. Finally, it has a very low coefficient of friction, making it non-stick and durable.

Why This Hybrid Design is Critical for Medical Use

This dual-material design creates a "best of both worlds" scenario. The Teflon shell protects the sensitive elastomer core from harsh disinfectants or bodily fluids that would otherwise cause it to degrade.

Simultaneously, the elastomer core provides the constant, gentle outward pressure—the "sealing force"—that a solid Teflon ring could not achieve on its own.

Key Advantages in Medical Applications

The specific properties of this construction make these O-rings uniquely suited for the demanding and sensitive context of medical technology.

Unmatched Chemical Resistance

Medical equipment must be regularly cleaned and sterilized, often with aggressive chemicals like alcohols, acids, and other disinfectants. The Teflon jacket is impervious to this chemical exposure, ensuring the seal does not break down, swell, or leach contaminants into the system.

Certified Biocompatibility

Patient safety is paramount. Teflon-encapsulated O-rings are manufactured to comply with strict regulatory standards, including FDA requirements and USP Class VI classification. This certification validates that the material is non-toxic and safe for use in medical devices.

Extended Lifespan and Reliability

By shielding the elastomer core from chemical attack and physical wear, the Teflon encapsulation significantly extends the operational life of the seal. This is crucial for the reliability of long-running equipment like dialysis machines and infusion pumps, where a seal failure would be critical.

Understanding the Trade-offs

While highly effective, it's important to understand the specific context where these O-rings perform best.

Solid Teflon vs. Encapsulated

A solid Teflon O-ring offers the same chemical resistance but lacks the elasticity of an encapsulated one. This rigidity makes it unsuitable for many applications that require a resilient, conforming seal. The encapsulated design provides the chemical properties of solid Teflon with the mechanical performance of rubber.

Application Constraints

Teflon-encapsulated O-rings are ideal for static (non-moving) and semi-dynamic (slow or infrequent movement) applications. In highly dynamic, high-speed, or high-pressure systems, the jacket could potentially experience wear or failure over time.

Installation Sensitivity

The Teflon jacket is durable but less forgiving than a standard elastomer O-ring. Care must be taken during installation to avoid scratching or nicking the surface, as any breach in the jacket could expose the core and compromise the entire seal.

Making the Right Choice for Your Device

Selecting the right seal requires aligning its properties with your primary design goal.

- If your primary focus is patient safety and biocompatibility: The USP Class VI and FDA compliance of the Teflon shell makes this design an essential choice.

- If your primary focus is resistance to harsh sterilization chemicals: The inert Teflon jacket ensures the seal's integrity over countless cleaning cycles, preventing device failure and contamination.

- If your primary focus is reliable sealing in devices like pumps or valves: The combination of an elastic core and a low-friction shell provides a durable and effective seal for static and semi-dynamic applications.

By understanding this hybrid design, you can confidently specify a sealing solution that delivers both robust mechanical performance and uncompromising medical safety.

Summary Table:

| Key Feature | Benefit for Medical Equipment |

|---|---|

| Teflon (PTFE/FEP/PFA) Shell | Provides chemical inertness, biocompatibility, and resistance to sterilization agents. |

| Elastomer Core (Silicone/FKM) | Delivers elasticity and consistent sealing force for reliable performance. |

| Hybrid Design | Combines the flexibility of rubber with the inertness of Teflon for optimal safety and function. |

| Regulatory Compliance | Meets FDA and USP Class VI standards for direct contact with bodily fluids. |

| Durability | Extends seal lifespan by protecting the core from chemical and physical degradation. |

Need a sealing solution that guarantees safety and reliability for your medical device?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including custom Teflon-encapsulated O-rings tailored for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a seal that meets exact specifications for biocompatibility, chemical resistance, and performance.

Contact us today at #ContactForm to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments