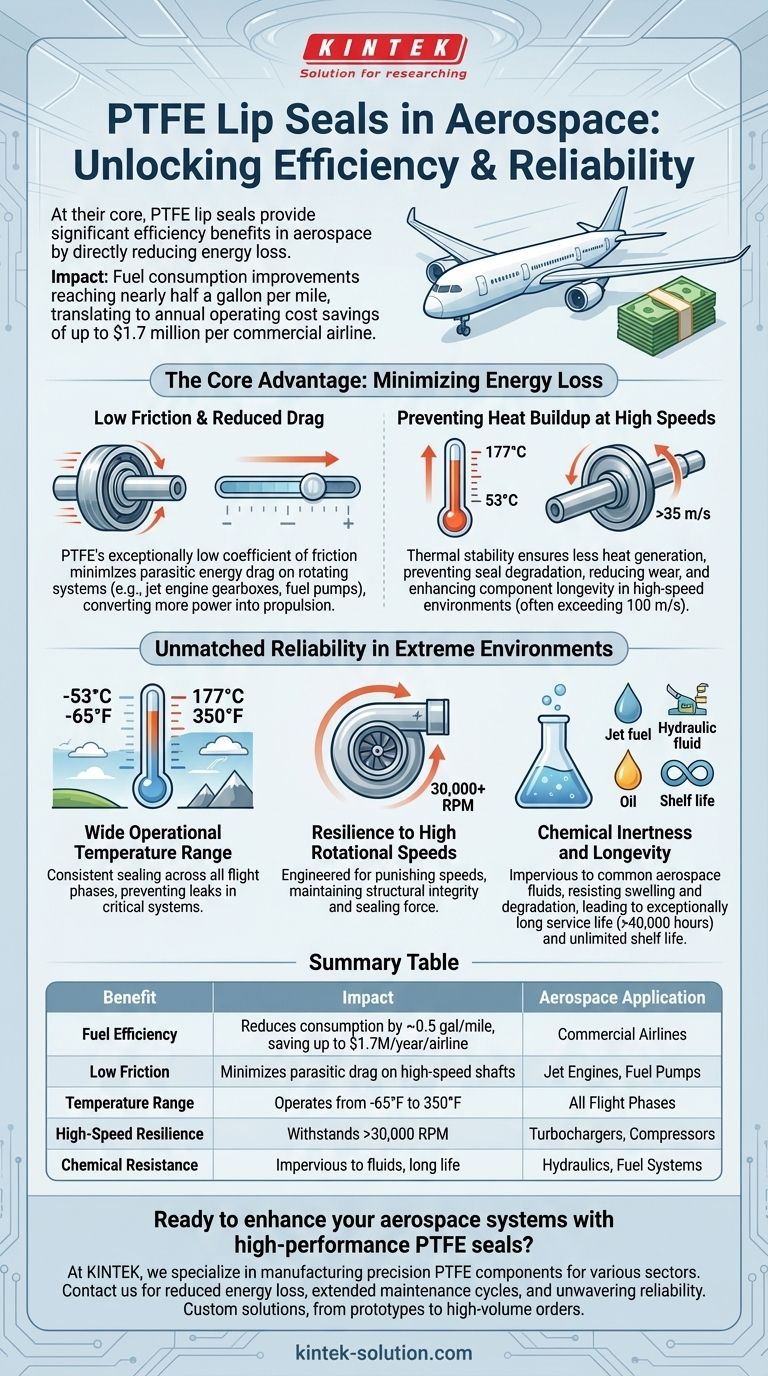

At their core, PTFE lip seals provide significant efficiency benefits in aerospace by directly reducing energy loss. The most dramatic impact is on fuel consumption, where improvements can reach nearly half a gallon per mile. For a commercial airline, this single component choice can translate into annual operating cost savings of up to $1.7 million.

The true value of PTFE seals is not just one feature, but how their fundamental material properties—exceptionally low friction and resilience to extreme conditions—work together. This synergy minimizes parasitic energy drag on rotating systems and ensures unwavering reliability where standard seals would quickly fail.

The Core Advantage: Minimizing Energy Loss

The primary efficiency gain from PTFE seals comes from their ability to reduce the energy wasted overcoming friction in high-speed rotating systems.

How PTFE Reduces Rotational Drag

PTFE, or polytetrafluoroethylene, has one of the lowest coefficients of friction of any solid material. This is its defining characteristic.

In an aerospace application like a jet engine gearbox or fuel pump, a seal is in constant contact with a rapidly spinning shaft. A standard elastomer seal creates significant frictional drag, forcing the engine to expend energy just to overcome it.

Because PTFE is so slick, it imparts far less drag on the shaft. This reduction in parasitic loss means more of the engine's power is used for its intended purpose, directly improving fuel efficiency.

Preventing Heat Buildup at High Speeds

Friction creates heat. In aerospace systems with shaft surface speeds often exceeding 35 m/s (and in some cases over 100 m/s), traditional seals can generate so much heat that they degrade, harden, and fail prematurely.

PTFE's low-friction nature means it generates significantly less heat. This thermal stability prevents seal failure, reduces wear on the shaft, and ensures the system operates within its designed temperature limits, enhancing both safety and component longevity.

Unmatched Reliability in Extreme Aerospace Environments

Beyond direct frictional efficiency, PTFE seals provide reliability benefits that are critical for aerospace operations. Their ability to perform under conditions that would destroy other materials prevents costly failures and extends maintenance cycles.

Wide Operational Temperature Range

Aerospace components must function flawlessly from a cold start on the ground to extreme heat at high altitude. PTFE seals operate consistently within a vast temperature range, typically from -53°C to 177°C (-65°F to 350°F).

This stability ensures a reliable seal is maintained regardless of the flight phase, preventing leaks in critical systems like hydraulics, fuel pumps, and actuators.

Resilience to High Rotational Speeds

PTFE seals are engineered for punishing rotational speeds. They are commonly used in turbochargers and compressors that can spin well over 30,000 RPM.

Unlike some elastomers that can distort or degrade under high centrifugal forces, PTFE maintains its structural integrity and sealing force, making it the default choice for high-RPM applications.

Chemical Inertness and Longevity

PTFE is nearly impervious to all common aerospace fluids, including aggressive hydraulic fluids, oils, and jet fuel. This chemical resistance prevents the material from swelling, shrinking, or degrading over time.

This results in an exceptionally long service life—with some industrial applications exceeding 40,000 maintenance-free hours—and an unlimited shelf life, which is a significant logistical advantage.

Common Pitfalls and Trade-offs

While highly effective, PTFE seals are not a universal replacement for all other seal types. Their unique properties require specific design considerations.

Design and Installation Sensitivity

PTFE is a polymer, not an elastomer. It is stiffer and has less "memory" than rubber. This means installation requires greater care to avoid nicking or scratching the sealing lip.

Furthermore, the hardware design, particularly the shaft's surface finish, is more critical for a PTFE seal to function correctly than for a more forgiving elastomer seal.

Managing Cold Flow

Under sustained pressure and temperature, PTFE can be susceptible to "cold flow," or creep. Modern PTFE seal compounds mitigate this by adding fillers (like glass fiber, carbon, or graphite), but it remains a fundamental material property that must be accounted for in the design of the seal and its housing.

Making the Right Choice for Your Application

Selecting the correct seal is a critical engineering decision based on the specific demands of the system.

- If your primary focus is maximizing fuel efficiency and reducing operating costs: PTFE lip seals offer a direct, measurable benefit by minimizing frictional energy loss on high-speed rotating shafts.

- If your primary focus is reliability in extreme temperatures and high speeds: PTFE's material stability across a wide thermal range and at extreme RPMs makes it the superior choice for critical systems like engine gearboxes, APUs, and generators.

- If your primary focus is extending maintenance intervals: The chemical inertness and exceptional wear resistance of PTFE provide a significantly longer operational life compared to traditional seals, reducing component replacement and aircraft downtime.

Ultimately, specifying PTFE seals in the right application is a foundational decision that enhances both the performance and the long-term economic viability of an aircraft.

Summary Table:

| Benefit | Impact in Aerospace Applications |

|---|---|

| Fuel Efficiency | Reduces consumption by nearly 0.5 gal/mile, saving up to $1.7M/year per airline |

| Low Friction | Minimizes parasitic drag on high-speed shafts (e.g., jet engines, fuel pumps) |

| Temperature Range | Operates from -65°F to 350°F, ensuring reliability across all flight phases |

| High-Speed Resilience | Withstands rotational speeds exceeding 30,000 RPM without degradation |

| Chemical Resistance | Impervious to jet fuel, hydraulic fluids, and oils; offers long service life |

Ready to enhance your aerospace systems with high-performance PTFE seals?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures that your aerospace applications benefit from reduced energy loss, extended maintenance cycles, and unwavering reliability in extreme environments.

Whether you need prototypes or high-volume orders, we deliver custom solutions tailored to your exact specifications. Contact us today to discuss how our PTFE seals can optimize your performance and cut operational costs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Crucibles for Laboratory and Industrial Applications

People Also Ask

- What factors should be considered when selecting a PTFE expansion joint? Ensure System Integrity and Safety

- What is the coefficient of friction for these o-rings? Don't Be Misled by a Single Number

- What are the advantages of PTFE/PFA lining in steel pipes? Achieve Superior Corrosion Resistance and Purity

- What are other names for Teflon encapsulated silicone o-rings? Find the Right High-Performance Seal

- What are the standard thickness options for PTFE sheets? Choose the Right Thickness for Your Application

- What factors should be considered when selecting PTFE gaskets based on their raw materials? Choose the Right Form for Your Application

- Why are PTFE guide strips suitable for the food and beverage industry? Ensure Safety, Compliance, and Reliability

- What are the main advantages of using Teflon sheets in engineering? Boost Efficiency & Durability