In the semiconductor industry, Polytetrafluoroethylene (PTFE) is a critical material used for high-purity fluid handling, wafer transport, and as a protective coating on manufacturing equipment. Its primary function is to prevent chemical corrosion and particulate contamination, which are two of the greatest threats to semiconductor yield.

The core reason PTFE is indispensable in semiconductor fabrication is its extreme chemical inertness. This property ensures that the ultra-pure chemicals used in manufacturing are never contaminated by the equipment they pass through, and the delicate silicon wafers are protected from corrosive process steps.

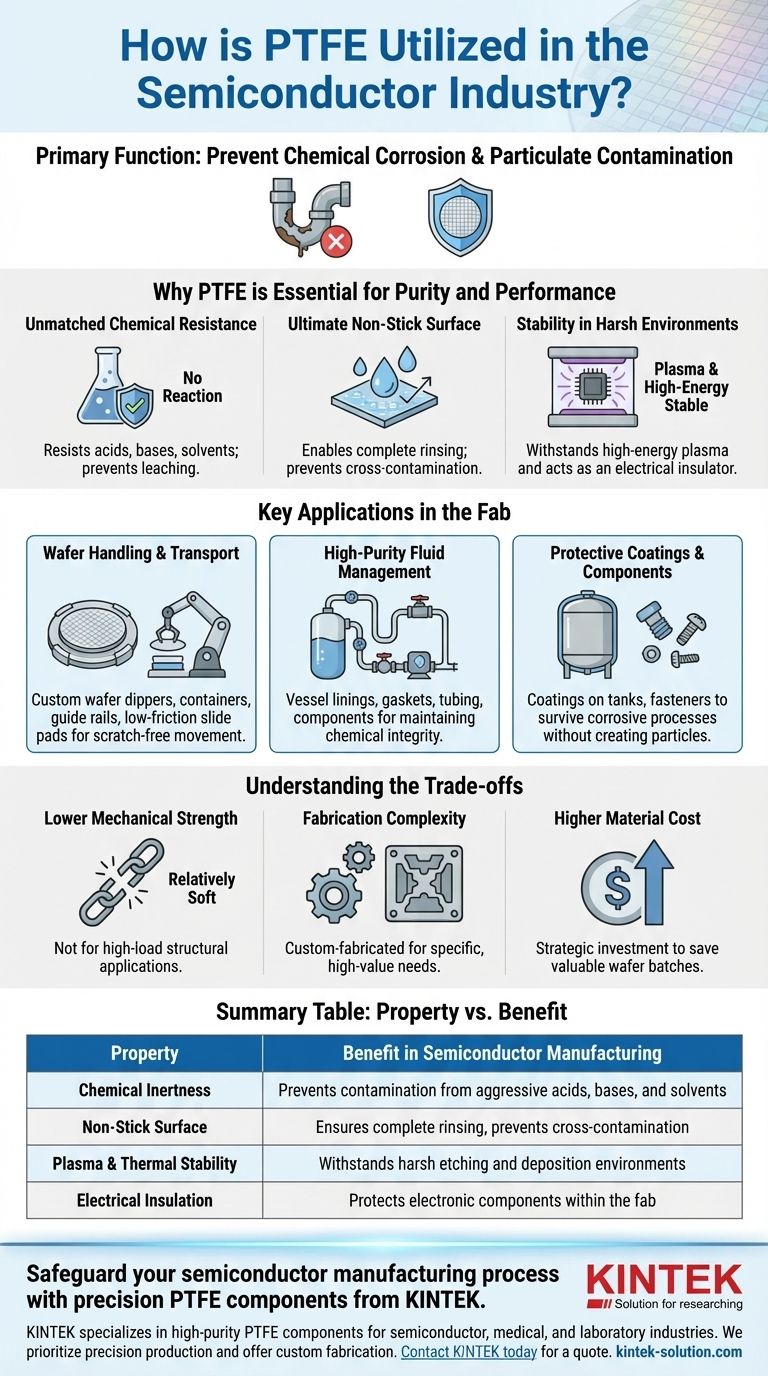

Why PTFE is Essential for Purity and Performance

The production of microchips involves hundreds of steps using highly aggressive chemicals and plasma environments. PTFE's unique combination of properties makes it one of the few materials that can withstand these conditions without degrading or contaminating the process.

Unmatched Chemical Resistance

Virtually no chemical can attack or degrade PTFE at temperatures used in semiconductor manufacturing. This includes the strong acids, bases, and solvents used for etching, cleaning, and photoresist stripping. This inertness prevents the material from leaching impurities into the process stream.

Ultimate Non-Stick Surface

PTFE's famous non-wetting (hydrophobic) and non-stick surface is vital for purity. It ensures that chemical residues can be completely rinsed away from wafer carriers, containers, and tubing, preventing cross-contamination between process steps.

Stability in Harsh Environments

Beyond chemical resistance, PTFE remains stable when exposed to the high-energy plasma used in certain etching and deposition processes. It is also an exceptional electrical insulator, a property leveraged in cable insulation and other electronic components within the fab.

Key Applications in the Fab

PTFE's properties are leveraged across the fabrication facility, particularly in areas where wafers or process chemicals are handled.

Wafer Handling and Transport

Components that come into direct contact with silicon wafers must be non-abrasive and chemically pure. PTFE is used for custom wafer dippers, containers, guide rails, and low-friction slide pads to move wafers safely through the production line without scratching or contamination.

High-Purity Fluid Management

The integrity of process chemicals is paramount. PTFE is the material of choice for vessel linings, gaskets, tubing, and components for pumps and valves used in high-purity chemical delivery systems. This ensures the chemical that reaches the wafer is identical to the chemical that left the source.

Protective Coatings and Components

Manufacturing equipment itself must be protected from corrosive chemicals. PTFE is used for coatings on tanks and reaction vessels and for fabricating smaller components like fasteners that must survive inside the process environment without corroding and creating particles.

Understanding the Trade-offs

While its properties are exceptional, PTFE is not a universal solution. Understanding its limitations is key to using it effectively.

Lower Mechanical Strength

Compared to metals or engineering plastics, PTFE is a relatively soft material. It is not suitable for high-load, structural applications where mechanical rigidity is the primary requirement.

Fabrication Complexity

PTFE can be more challenging to machine and mold than more common polymers. This is why many PTFE components are custom-fabricated for specific, high-value applications where its unique properties are non-negotiable.

Higher Material Cost

As a high-performance polymer, PTFE is more expensive than commodity plastics. Its use is a strategic investment, justified in applications where preventing a single contamination event can save an entire batch of valuable wafers.

Making the Right Choice for Your Goal

Selecting the right material is a balance of performance, cost, and process requirements.

- If your primary focus is preventing chemical contamination: PTFE is the industry standard for any surface that directly contacts wafers or high-purity process fluids.

- If your primary focus is on non-critical structural parts: For components not exposed to harsh chemicals, other engineering plastics or metals may provide better mechanical performance and lower cost.

- If your primary focus is maximizing equipment uptime: Using PTFE for linings and components protects capital equipment from corrosion, extending its life and reducing maintenance.

Ultimately, leveraging PTFE is a foundational strategy for safeguarding process integrity and maximizing final product yield in semiconductor manufacturing.

Summary Table:

| Property | Benefit in Semiconductor Manufacturing |

|---|---|

| Chemical Inertness | Prevents contamination from aggressive acids, bases, and solvents |

| Non-Stick Surface | Ensures complete rinsing, prevents cross-contamination |

| Plasma & Thermal Stability | Withstands harsh etching and deposition environments |

| Electrical Insulation | Protects electronic components within the fab |

Safeguard your semiconductor manufacturing process with precision PTFE components from KINTEK.

As detailed in this article, PTFE's unique properties are non-negotiable for preventing contamination and corrosion in high-value semiconductor fabrication. KINTEK specializes in manufacturing high-purity PTFE components—including custom seals, liners, wafer handling tools, and labware—specifically for the semiconductor, medical, and laboratory industries.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders, ensuring your equipment is protected and your yield is maximized.

Contact KINTEK today to discuss your specific PTFE component needs and request a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Scrapers and Shovels for Demanding Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What role do PTFE gaskets play in the energy and power industry? Ensuring Safety and Reliability in Critical Infrastructure

- Do lubricating agents impact particle generation in PTFE? Yes, and here's how to control it.

- What is PTFE, and why is it used in expansion joints? Superior Chemical & Thermal Stability

- What are the benefits of PTFE with aramid in gland packings? Achieve Superior Sealing Under Extreme Conditions

- How do PEEK and PTFE compare in terms of friction and chemical compatibility? Choose the Right High-Performance Polymer

- What are the core materials used in TFE Encapsulated gaskets and their applications? A Guide to Superior Sealing

- What are the steps involved in PTFE isostatic pressing? A Guide to Uniform, Complex Parts

- What are some installation tips for PTFE sheets? Achieve a Perfect, Leak-Free Seal