At their core, TFE encapsulated gaskets are composite seals made of a resilient inner material, typically Silicone or Viton, which is completely enclosed in a thin, protective shell of a fluoropolymer like FEP. This design combines the superior chemical resistance of the outer shell with the excellent memory and sealing force of the elastomeric core. They are primarily used in applications where chemical purity and a reliable seal are critical, such as chemical processing, food and beverage production, and pharmaceutical manufacturing.

The fundamental advantage of a TFE encapsulated gasket is its ability to provide the chemical inertness of solid PTFE while overcoming its main drawbacks—poor memory and a tendency to creep. It achieves this by using a flexible elastomeric core to maintain a constant, reliable sealing pressure.

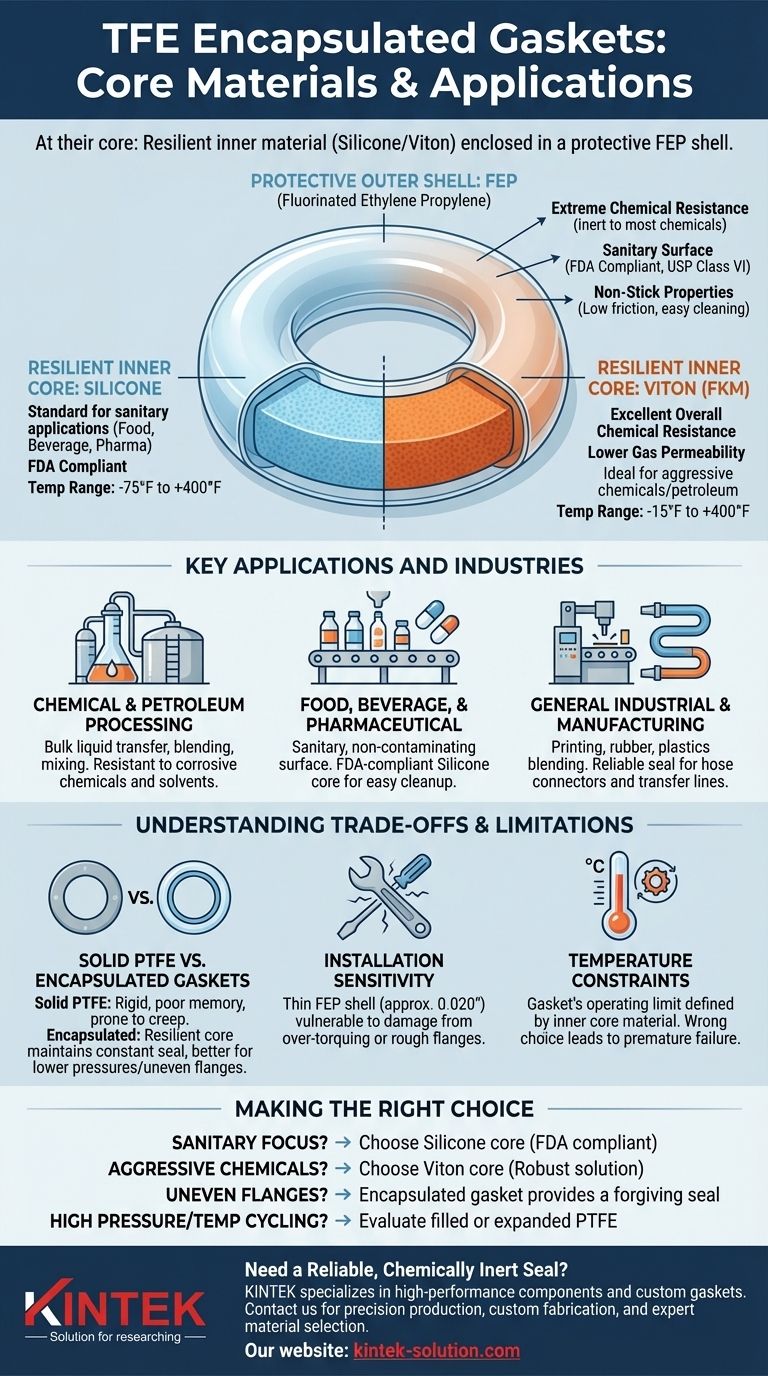

The Anatomy of an Encapsulated Gasket

Understanding these gaskets requires looking at their two distinct components and the engineering principle that combines them. Each part plays a specific, critical role in the gasket's overall performance.

The Protective Outer Shell: FEP

The outer shell is the component that comes into contact with the process fluid. It is typically made from a seamless layer of FEP (Fluorinated Ethylene Propylene), a type of TFE fluoropolymer.

This shell provides the gasket's primary benefits:

- Extreme Chemical Resistance: FEP is chemically inert to nearly all industrial chemicals and solvents, even at elevated temperatures.

- Sanitary Surface: The material is FDA compliant and USP Class VI approved, making it ideal for sanitary applications by eliminating contamination risks.

- Non-Stick Properties: A very low coefficient of friction and a non-porous surface simplify cleaning and prevent process media from adhering to the gasket.

The Resilient Inner Core

The inner core is what gives the gasket its flexibility, memory, and ability to create a tight seal, especially on surfaces that aren't perfectly flat. The choice of core material dictates the gasket's temperature range and optimal application.

The two most common core materials are:

- Silicone: This is the standard choice for sanitary applications in the food, beverage, and pharmaceutical industries. It is FDA compliant and offers a wider operational temperature range, typically from -75°F to +400°F.

- Viton: Chosen for its excellent overall chemical resistance and lower gas permeability. It is ideal for aggressive chemical processing and petroleum applications, with a typical temperature range of -15°F to +400°F.

Key Applications and Industries

The unique dual-material construction makes encapsulated gaskets a universal sealing solution in demanding environments.

Chemical and Petroleum Processing

These gaskets are extensively used for bulk liquid transfer, from delivery trucks to storage tanks and from storage to process areas. Their resistance to corrosive chemicals and solvents makes them suitable for blending, mixing, and distribution lines.

Food, Beverage, and Pharmaceutical

The combination of a sanitary, non-contaminating FEP surface and an FDA-compliant silicone core is critical for these industries. The non-stick surface ensures easy cleanup and prevents batch-to-batch contamination.

General Industrial and Manufacturing

In processes like printing, rubber manufacturing, and plastics blending, these gaskets provide a reliable seal for hose connectors and transfer lines handling a variety of resins and liquids.

Understanding the Trade-offs and Limitations

While highly effective, encapsulated gaskets are not a universal solution. An objective assessment requires understanding their limitations.

Solid PTFE vs. Encapsulated Gaskets

It is crucial not to confuse encapsulated gaskets with solid PTFE gaskets. A solid PTFE gasket is rigid, has poor memory, and is prone to cold flow or "creep," which can lead to leaks over time.

An encapsulated gasket uses its elastomeric core to maintain a live, constant seal, making it far superior for lower-pressure applications or for sealing flanges that may be slightly uneven.

Installation Sensitivity

The protective FEP shell is relatively thin (often around 0.020 inches). This makes it vulnerable to damage during installation. Over-torquing the gasket or installing it on a flange with a rough, scratched, or serrated surface can easily puncture the shell, compromising its chemical resistance and leading to failure.

Temperature Constraints

The gasket's operating temperature is limited by its core material. While the FEP shell performs well at high temperatures, the elastomer inside defines the ultimate service range. Selecting the wrong core for your process temperature can lead to premature failure.

Making the Right Choice for Your Goal

Selecting the correct gasket requires matching its material composition to your specific operational needs.

- If your primary focus is sanitary processing (food, pharma): Choose a TFE Encapsulated gasket with a silicone core for its FDA compliance and broad temperature range.

- If your primary focus is aggressive chemical resistance: A Viton core provides a robust solution for a wide variety of industrial chemicals and petroleum products.

- If you are sealing an uneven or imperfect flange: The resilience of an encapsulated gasket provides a more reliable and forgiving seal than a rigid, solid PTFE gasket.

- If you face extremely high pressures or sharp temperature cycling: You may need to evaluate filled or expanded PTFE gaskets, which are designed to better resist creep under high mechanical load.

Understanding this dual-material construction empowers you to select a seal that offers both uncompromising chemical purity and reliable mechanical performance.

Summary Table:

| Component | Material Options | Key Properties | Primary Use Case |

|---|---|---|---|

| Outer Shell | FEP (Fluorinated Ethylene Propylene) | Extreme chemical resistance, sanitary, non-stick | Protects against corrosive media, ensures purity |

| Inner Core | Silicone | FDA compliant, temp range: -75°F to +400°F | Sanitary applications (food, beverage, pharma) |

| Inner Core | Viton (FKM) | Excellent chemical resistance, temp range: -15°F to +400°F | Aggressive chemical and petroleum processing |

Need a Reliable, Chemically Inert Seal?

TFE encapsulated gaskets are engineered for demanding applications where failure is not an option. At KINTEK, we specialize in manufacturing high-performance PTFE and FEP components, including custom encapsulated gaskets, for the semiconductor, medical, laboratory, and industrial sectors.

We provide:

- Precision Production: Consistent quality and reliable performance for your critical processes.

- Custom Fabrication: From prototype development to high-volume orders, tailored to your exact specifications and flange dimensions.

- Expert Material Selection: Guidance on choosing the right core (silicone or Viton) for your specific temperature and chemical resistance requirements.

Ensure a leak-free, contaminant-free seal in your system. Contact KINTEK today to discuss your application and request a quote for custom encapsulated gaskets.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials