While both PEEK and PTFE are elite high-performance polymers, they are not interchangeable. PTFE offers near-universal chemical inertness, making it the default choice for extreme chemical environments. PEEK, however, provides far superior mechanical strength, especially under high pressure and temperature, making it the choice for structurally demanding applications.

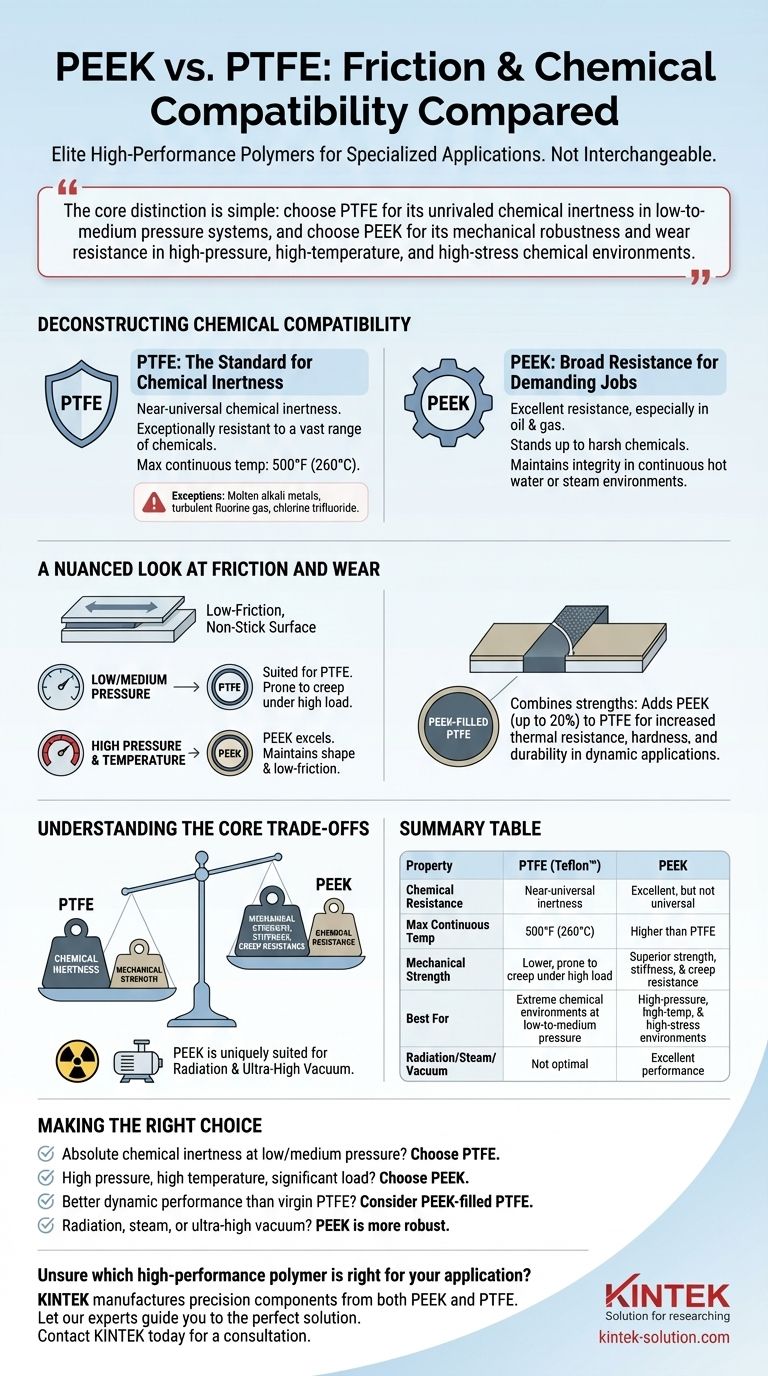

The core distinction is simple: choose PTFE for its unrivaled chemical inertness in low-to-medium pressure systems, and choose PEEK for its mechanical robustness and wear resistance in high-pressure, high-temperature, and high-stress chemical environments.

Deconstructing Chemical Compatibility

The term "good chemical compatibility" applies to both materials, but the degree and nature of their resistance differ significantly.

PTFE: The Standard for Chemical Inertness

Polytetrafluoroethylene (PTFE) is famous for being one of the most chemically inert materials known. It is exceptionally resistant to a vast range of chemicals.

This broad inertness holds true up to its maximum continuous operating temperature of 500°F (260°C).

PEEK: Broad Resistance for Demanding Jobs

Polyetheretherketone (PEEK) also offers excellent chemical resistance. It stands up well against many harsh chemicals, particularly in oil and gas applications.

PEEK maintains its integrity in environments with continuous exposure to hot water or steam, which can be a weakness for other polymers.

The Specific Exceptions for PTFE

While nearly inert, PTFE does have a few known vulnerabilities. It is not compatible with molten alkali metals (like sodium), turbulent fluorine gas, and certain highly reactive fluorinating agents such as chlorine trifluoride (ClF3).

A Nuanced Look at Friction and Wear

Both materials are known for their low coefficient of friction, making them ideal for seals and bearings. However, their performance under load is a critical differentiator.

Low Friction as a Shared Trait

In simple, low-load scenarios, both PEEK and PTFE provide a low-friction, non-stick surface. This shared characteristic is foundational to their use in sealing applications.

The Decisive Role of Pressure

The primary difference emerges under mechanical stress. PEEK excels in high-pressure and high-temperature conditions, maintaining its shape and low-friction properties.

PTFE is better suited for low-to-medium pressure applications. Under high loads, it can be prone to creep or deformation, which can compromise sealing performance.

Combining Strengths: PEEK-Filled PTFE

To bridge the gap, composites like PEEK-filled PTFE exist. Adding PEEK (up to 20%) to a PTFE base increases thermal resistance, surface hardness, and overall durability, making it superior for dynamic applications compared to virgin PTFE.

Understanding the Core Trade-offs

Selecting the right material requires acknowledging the fundamental trade-off between absolute chemical inertness and mechanical performance.

Mechanical Strength vs. Chemical Inertness

PTFE's primary advantage is its near-universal chemical inertness. Its primary disadvantage is its relative softness and lower mechanical strength.

PEEK's main advantage is its outstanding mechanical strength, stiffness, and creep resistance at high temperatures. Its chemical resistance, while excellent, is not as absolute as PTFE's.

Application-Specific Strengths

PEEK is uniquely suited for environments involving radiation (nuclear applications) or ultra-high vacuum pressures, where PTFE may not be the optimal choice.

Making the Right Choice for Your Application

Your final decision should be driven by the most demanding aspect of your operating environment.

- If your primary focus is absolute chemical inertness against aggressive media at low-to-medium pressure: Choose PTFE for its unrivaled and near-universal resistance.

- If your application involves high pressure, high temperature, and significant mechanical load: Choose PEEK for its superior strength, stiffness, and resistance to wear and creep.

- If you need better performance than virgin PTFE in a dynamic sealing application: Consider a PEEK-filled PTFE composite to improve hardness and wear properties.

- If your environment includes radiation, steam, or ultra-high vacuum: PEEK is the more robust and reliable choice.

Ultimately, a clear understanding of your application's pressure, temperature, and specific chemical challenges will guide you to the correct material.

Summary Table:

| Property | PTFE (Teflon™) | PEEK |

|---|---|---|

| Chemical Resistance | Near-universal inertness | Excellent, but not universal |

| Max Continuous Temp | 500°F (260°C) | Higher than PTFE |

| Mechanical Strength | Lower, prone to creep under high load | Superior strength, stiffness, and creep resistance |

| Best For | Extreme chemical environments at low-to-medium pressure | High-pressure, high-temperature, and high-stress environments |

| Radiation/Steam/Vacuum | Not optimal | Excellent performance |

Unsure which high-performance polymer is right for your application?

KINTEK manufactures precision components from both PEEK and PTFE, including seals, liners, and custom labware. Our expertise helps semiconductor, medical, laboratory, and industrial clients select the optimal material for their specific pressure, temperature, and chemical challenges.

We offer custom fabrication from prototypes to high-volume orders, ensuring your components meet exact performance requirements.

Let our experts guide you to the perfect solution. Contact KINTEK today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications