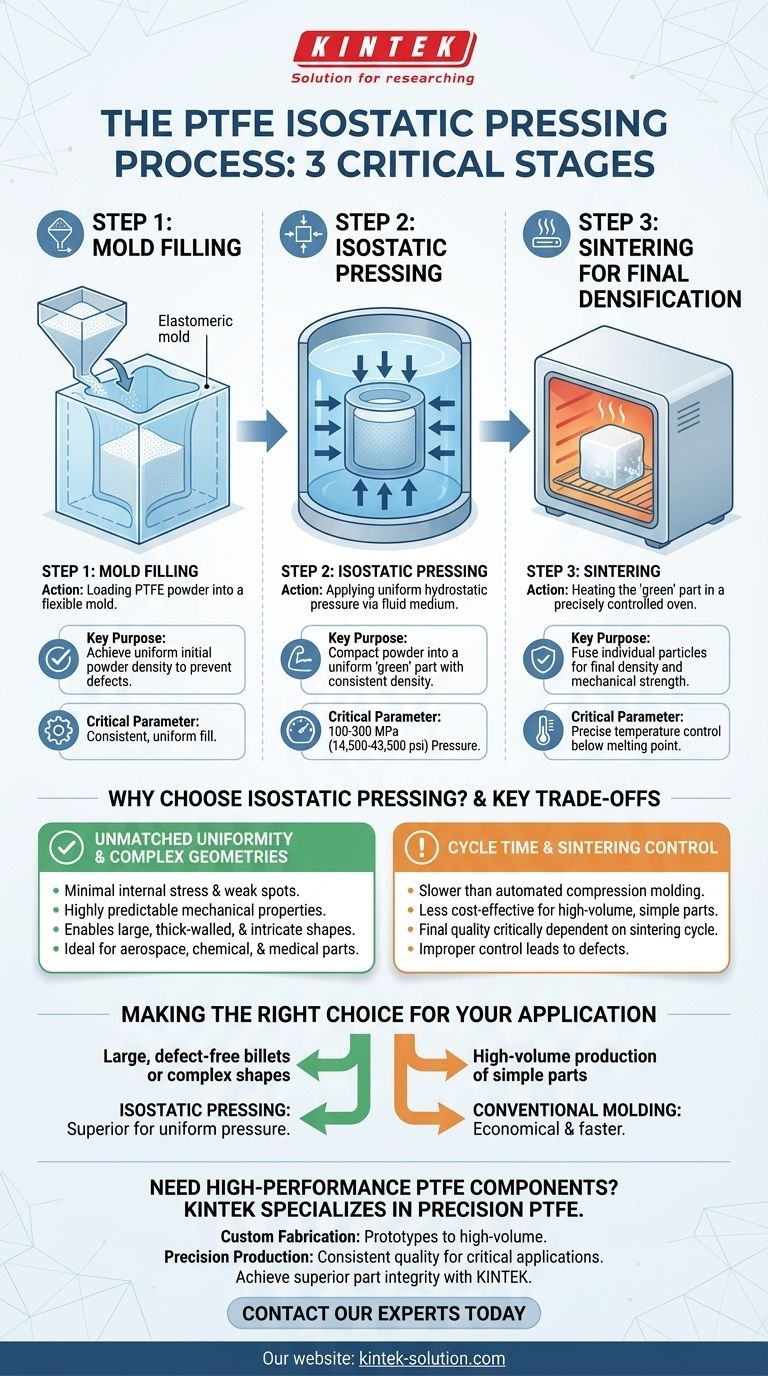

At its core, the isostatic pressing of Polytetrafluoroethylene (PTFE) is a three-stage manufacturing process. It involves filling a flexible mold with PTFE powder, compacting the powder by applying uniform pressure from all directions using a fluid medium, and finally sintering the resulting part at high temperature to achieve its final density and strength.

This method is specifically engineered to overcome the limitations of traditional pressing, enabling the creation of large or complex PTFE components with exceptionally uniform density and minimal internal stress.

A Step-by-Step Breakdown of the Process

Isostatic pressing transforms loose PTFE powder into a solid, high-performance component. Each step is critical for achieving the desired material properties.

Step 1: Mold Filling

The process begins by loading fine PTFE powder into a flexible, elastomeric mold, often made of polyurethane or similar materials.

The key to this stage is achieving a uniform fill. Any variations in powder density at this point can lead to defects in the final product.

Step 2: Applying Uniform Hydrostatic Pressure

The sealed mold is submerged in a fluid—typically water or oil—within a high-pressure chamber.

Pressure is then applied to this fluid, which transmits it equally and simultaneously to all surfaces of the flexible mold. This pressure is significant, typically ranging from 100 to 300 MPa (14,500 to 43,500 psi).

This uniform compaction is the defining feature of isostatic pressing, creating a pre-sintered part, often called a "green" part, with consistent density throughout.

Step 3: Sintering for Final Densification

The green part is carefully ejected from the mold. While it holds its shape, it is still chalky and mechanically weak.

To achieve its final properties, the part undergoes sintering. It is heated in a precisely controlled oven to a high temperature just below PTFE's melting point. This fuses the individual polymer particles, eliminates voids, and creates a dense, solid component.

Why Choose Isostatic Pressing for PTFE?

Understanding the advantages of this method reveals why it is specified for demanding applications.

Unmatched Part Uniformity

Unlike traditional pressing that applies force from one or two directions, isostatic pressure ensures every part of the component is compacted equally.

This minimizes weak spots, reduces internal stresses, and results in highly predictable mechanical properties, which is crucial for parts like precision seals and bearings.

Freedom for Complex and Large Geometries

The use of a flexible mold and uniform pressure makes it possible to produce shapes that are difficult or impossible with rigid dies.

This method is ideal for manufacturing large billets, thick-walled tubes, and intricate components for the aerospace, chemical processing, and medical industries.

Understanding the Key Trade-offs

While powerful, isostatic pressing is not the universal solution for all PTFE parts. Objectivity requires acknowledging its specific considerations.

Cycle Time and Throughput

The process of filling, sealing, pressurizing, and de-pressurizing the chamber is inherently slower than automated compression molding.

Therefore, it is generally not the most cost-effective method for producing very high volumes of small, simple parts.

Critical Sintering Control

The final quality of the part is exceptionally dependent on the sintering cycle.

Improper control of the heating rate, peak temperature, or cooling rate can lead to defects such as cracking or inadequate densification, compromising the component's performance.

Making the Right Choice for Your Application

Selecting the correct manufacturing process depends entirely on the component's geometry, size, and performance requirements.

- If your primary focus is producing large, defect-free billets or complex shapes: Isostatic pressing is the superior method due to its uniform pressure application.

- If your primary focus is high-volume production of simple parts like small gaskets or washers: Conventional compression molding is likely the more economical and faster choice.

By understanding this process, you can confidently specify a manufacturing method that ensures the integrity and performance required for your most critical PTFE components.

Summary Table:

| Step | Key Action | Purpose | Key Parameter |

|---|---|---|---|

| 1. Mold Filling | Loading PTFE powder into a flexible mold | Achieve uniform initial powder density | Consistent fill to prevent defects |

| 2. Isostatic Pressing | Applying fluid pressure from all directions | Compact powder into a uniform "green" part | 100-300 MPa (14,500-43,500 psi) |

| 3. Sintering | Heating the "green" part in a controlled oven | Fuse particles for final density and strength | Precise temperature control below melting point |

Need High-Performance PTFE Components?

KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, and industrial sectors. Our expertise in isostatic pressing ensures your parts have uniform density and minimal internal stress, even for large or complex geometries.

We provide:

- Custom Fabrication: From prototypes to high-volume orders.

- Precision Production: Ensuring consistent quality for critical applications.

Let us help you achieve superior part integrity. Contact our experts today to discuss your project requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What material are typical rotary seals made of and what are their limitations? Choose the Right Seal for Your Application

- What is a PTFE cylindrical bush and where is it commonly used? | High-Performance Bushing Guide

- How can the bore design of a PTFE seal be modified for higher speed or pressure? Optimize for Extreme Conditions

- What are the advantages of unreinforced PTFE laminates? Achieve Ultimate Signal Integrity for High-Frequency Designs

- What are the key benefits of heat-resistant Teflon sheets for printing? Protect Your Prints & Equipment

- What other specialized applications use PTFE lip seals? Ensure Reliability in Aerospace, Medical, and Automotive Systems

- What are the special features of PTFE that make it suitable for medical applications? Unlock Superior Biocompatibility & Performance

- How do PTFE O-rings perform against chemicals? Achieve Unmatched Chemical Resistance