Properly installing a PTFE sheet requires meticulous preparation and a technique suited to the application. The most critical steps are ensuring the target surface is perfectly clean and free of contaminants, using a sharp tool for precise cuts, and applying firm, even pressure for adhesive-backed variants.

The success of a PTFE sheet installation is determined before the sheet is even applied. Your focus should be on immaculate surface preparation and using the correct technique for your specific application, whether it's for a simple liner or a critical gasket.

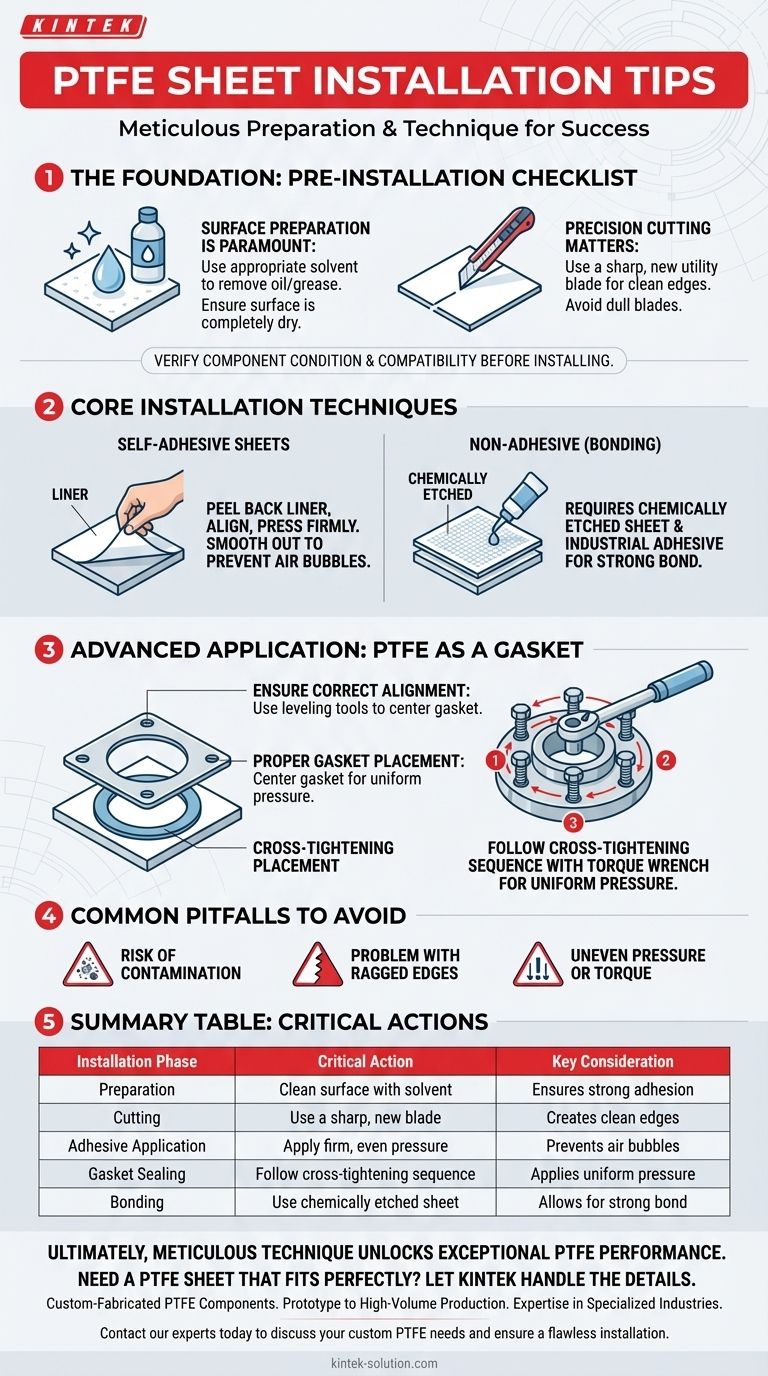

The Foundation: Pre-Installation Checklist

Success with PTFE begins with rigorous preparation. Skipping these foundational steps is the most common source of installation failure.

Surface Preparation is Paramount

The surface you are applying the PTFE sheet to must be completely clean. Any dust, debris, or oily residue will compromise the bond and performance.

Use an appropriate solvent to remove any grease or oil, and ensure the surface is dry before proceeding.

Precision Cutting Matters

PTFE can be difficult to cut cleanly. Using a dull blade will create rough, jagged edges that can become failure points, especially in sealing applications.

Always use a sharp, new utility blade or specialized cutting tool. Make your cuts with confidence and precision to ensure a smooth, clean edge.

Verify Component Condition

Before installing a PTFE sheet as a gasket or seal, inspect the components themselves. For example, if working with a valve, check its condition for any damage that could interfere with a proper seal.

Ensure the PTFE sheet's properties (temperature range, chemical resistance) are fully compatible with the demands of the application.

Core Installation Techniques

The method of installation depends on whether the sheet is self-adhesive or requires a separate bonding agent.

For Self-Adhesive Sheets

Self-adhesive PTFE sheets offer a straightforward installation process. Carefully peel back a small portion of the adhesive liner to start.

Align the sheet precisely, then press it down firmly. Slowly peel off the remaining backing while smoothing the sheet onto the surface to prevent air bubbles and ensure a complete bond.

For Non-Adhesive Sheets (Bonding)

Standard PTFE is famously non-stick, making it impossible to glue without special treatment. For these applications, you must use a sheet that has been chemically etched on one side.

This etching process modifies the surface chemistry of the PTFE, allowing it to form a strong bond with an appropriate epoxy or other adhesive.

Advanced Application: PTFE as a Gasket

When using PTFE for a critical seal or gasket, the mechanical aspects of the installation are just as important as the surface preparation.

Ensuring Correct Alignment

Proper alignment is crucial for an effective seal. Use leveling tools to ensure the components are perfectly situated before applying any pressure.

Misalignment is a primary cause of gasket failure and leaks, regardless of the material quality.

Proper Gasket Placement

Position the gasket carefully to ensure it is centered correctly. An off-center gasket will not experience uniform pressure and is likely to fail.

Correct Bolting & Torque

Follow a proper cross-tightening sequence for any bolts. This method involves tightening bolts in a star pattern to apply pressure evenly across the gasket surface.

Use a torque wrench to apply the correct, specified amount of force. Both under-tightening and over-tightening can lead to seal failure.

Common Pitfalls to Avoid

Understanding what can go wrong is key to ensuring a successful installation.

The Risk of Contamination

Even a small amount of dust or a fingerprint's worth of oil can create a point of failure for an adhesive or a seal. This is the most critical and easiest mistake to avoid.

The Problem with Ragged Edges

Rough edges from a poor cut are not just a cosmetic issue. They create stress concentration points that can lead to tearing or compromise the integrity of a seal over time.

Uneven Pressure or Torque

Applying uneven pressure during installation of an adhesive sheet can create weak spots or bubbles. In a gasket application, uneven torque is a direct path to a leak.

How to Apply This to Your Project

Your installation priority should be guided by your end goal.

- If your primary focus is creating a low-friction liner: Concentrate on flawless surface cleanliness and a smooth, bubble-free application of the sheet.

- If your primary focus is creating a critical seal or gasket: Emphasize precise alignment, a cross-tightening bolt sequence, and using a torque wrench.

- If your primary focus is bonding to another surface: You must start with a chemically etched PTFE sheet and use an appropriate industrial adhesive.

Ultimately, meticulous technique is what unlocks the exceptional performance properties of PTFE.

Summary Table:

| Installation Phase | Critical Action | Key Consideration |

|---|---|---|

| Preparation | Clean surface with solvent | Ensures strong adhesion, prevents contamination |

| Cutting | Use a sharp, new utility blade | Creates clean edges, prevents tearing and failure points |

| Adhesive Application | Apply firm, even pressure | Prevents air bubbles and weak spots for self-adhesive sheets |

| Gasket Sealing | Follow a cross-tightening bolt sequence | Applies uniform pressure, prevents leaks |

| Bonding | Use a chemically etched PTFE sheet | Allows for a strong bond with industrial adhesives |

Need a PTFE Sheet That Fits Perfectly? Let KINTEK Handle the Details.

Proper installation starts with a high-quality, precision-manufactured PTFE component. Whether you're in the semiconductor, medical, laboratory, or industrial sector, KINTEK delivers:

- Custom-Fabricated PTFE Components: We manufacture seals, liners, labware, and more to your exact specifications, ensuring a perfect fit for your application.

- Prototype to High-Volume Production: We support your project from initial concept through to full-scale manufacturing.

- Expertise in Specialized Industries: Our components are designed to meet the stringent demands of critical environments.

Don't let installation challenges compromise your project's integrity. Contact our experts today to discuss your custom PTFE needs and ensure a flawless installation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection