At its core, Polytetrafluoroethylene (PTFE) is a high-performance synthetic fluoropolymer prized for its unique material properties. It is used in expansion joints specifically for its ability to solve problems that conventional rubber and metal joints cannot, primarily in applications demanding extreme chemical resistance and a wide operating temperature range.

While many materials can absorb movement, PTFE is chosen when system integrity depends on a material that remains completely non-reactive. Its selection is driven by the need for chemical and thermal stability in environments where other materials would corrode, degrade, or contaminate the process media.

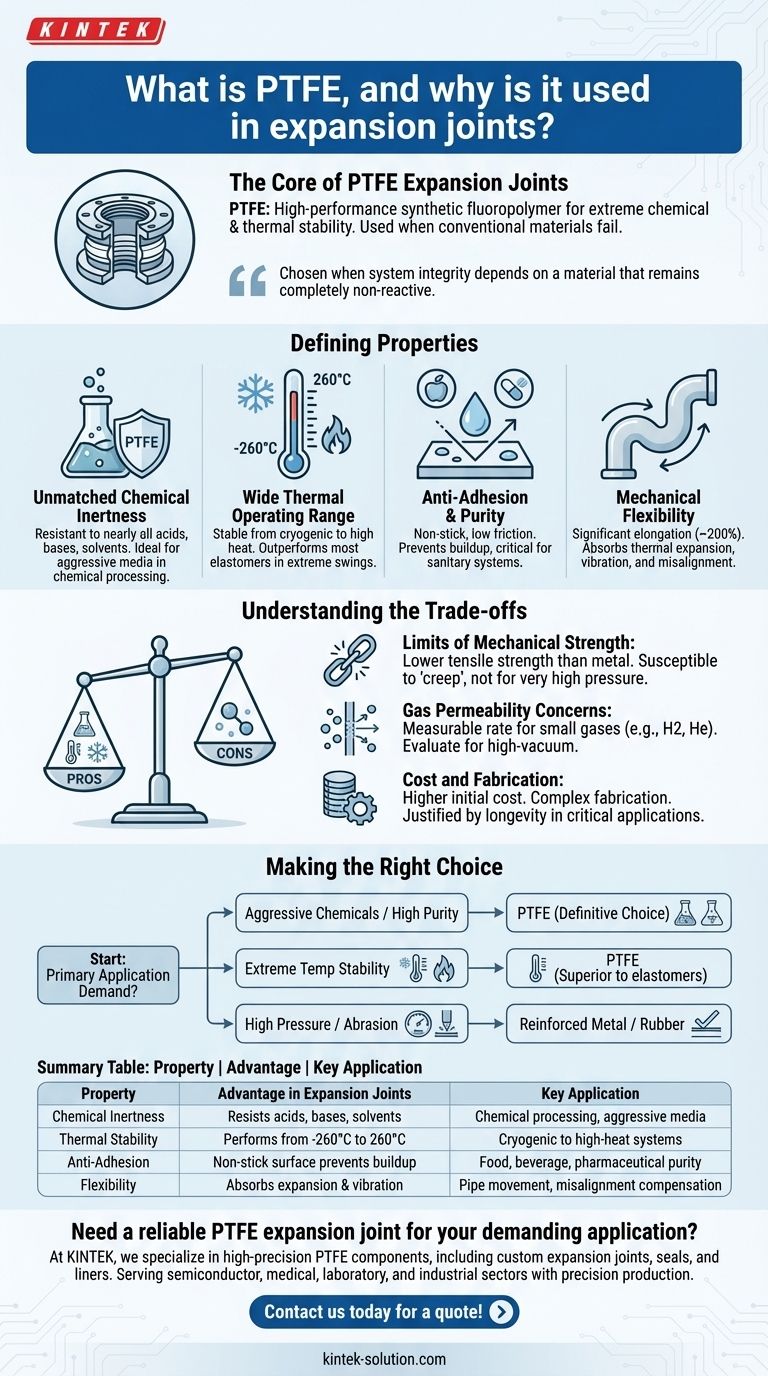

The Defining Properties of PTFE

To understand why PTFE is specified for demanding expansion joint applications, we must look at its distinct material characteristics. These properties work in combination to provide a unique solution for process industries.

Unmatched Chemical Inertness

PTFE is famous for being almost completely inert. It is resistant to nearly all industrial chemicals, solvents, acids, and bases, even at elevated temperatures.

This makes it the default choice for systems handling aggressive media, such as those found in chemical processing, where a standard rubber or metal joint would quickly fail.

Wide Thermal Operating Range

PTFE maintains its properties across an exceptionally broad temperature spectrum, typically from cryogenic lows of -260°C up to high-heat applications of 260°C (-436°F to 500°F).

This stability allows it to be used in processes that experience extreme temperature swings, outperforming most elastomers which would become brittle at low temperatures or degrade at high temperatures.

Anti-Adhesion and Purity

The material has an extremely low coefficient of friction and is highly non-stick, a property well-known from its use in cookware.

In an industrial context, this prevents viscous media from building up on the expansion joint's surface. This is critical in food, beverage, and pharmaceutical applications where cleanliness is paramount and media buildup can lead to contamination. Its inherent purity and biocompatibility are essential in these sanitary systems.

Mechanical Flexibility

While not as elastic as rubber, PTFE has significant elongation capabilities (over 200%). This allows it to flex and move, effectively absorbing thermal expansion, equipment vibration, and minor pipe misalignment.

This flexibility is the core function of an expansion joint, and PTFE provides it without compromising its other critical properties.

Understanding the Trade-offs

No material is perfect for every application. Choosing PTFE involves accepting a specific set of performance trade-offs compared to metal or rubber.

The Limits of Mechanical Strength

PTFE is a relatively soft plastic with a lower tensile strength than metal. It is more susceptible to "creep," a slow deformation under sustained pressure, and can be damaged by abrasive media.

For this reason, PTFE expansion joints are often not suitable for very high-pressure systems or lines carrying abrasive slurries unless they are specifically designed with reinforcement.

Gas Permeability Concerns

PTFE has a measurable rate of gas permeability, particularly with smaller gas molecules like hydrogen and helium. While it is hydrophobic and repels liquids, it is not a perfect gas seal.

In high-vacuum applications or systems requiring the absolute containment of specific gases, this property must be carefully evaluated, as it could lead to slow leakage over time.

Cost and Fabrication

As a high-performance polymer, PTFE is significantly more expensive than common elastomers like EPDM or neoprene. The processes for molding and fabricating PTFE components are also more complex and costly.

This higher initial cost is justified by its longer service life and the prevention of failure in applications where other materials are not viable.

Making the Right Choice for Your System

Selecting the correct expansion joint material requires matching the material's properties to the primary demands of your application.

- If your primary focus is handling aggressive chemicals or high-purity media: PTFE is the definitive choice due to its chemical inertness and non-stick surface.

- If your primary focus is extreme temperature stability (both cryogenic and high heat): PTFE's wide operating range makes it superior to most rubber elastomers.

- If your primary focus is high pressure containment or abrasion resistance: A reinforced metal or specialized abrasion-resistant rubber expansion joint will likely be a more durable and cost-effective solution.

By understanding PTFE's unique strengths and limitations, you can confidently specify the right material to ensure system integrity and longevity.

Summary Table:

| Property | Advantage in Expansion Joints | Key Application |

|---|---|---|

| Chemical Inertness | Resists nearly all acids, bases, and solvents | Chemical processing, aggressive media |

| Thermal Stability | Performs from -260°C to 260°C | Cryogenic to high-heat systems |

| Anti-Adhesion | Non-stick surface prevents buildup | Food, beverage, pharmaceutical purity |

| Flexibility | Absorbs thermal expansion and vibration | Pipe movement, misalignment compensation |

Need a reliable PTFE expansion joint for your demanding application?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including custom expansion joints, seals, and liners. Our expertise ensures your system benefits from PTFE's superior chemical resistance, thermal stability, and purity—whether you're in the semiconductor, medical, laboratory, or industrial sector.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders. Let us help you solve your most challenging fluid handling problems with a solution built for longevity and performance.

Contact us today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How does a PTFE lined butterfly valve compare to other valve types? A Guide to Superior Sealing & Chemical Resistance

- What are the disadvantages of unreinforced PTFE laminates? Navigating Manufacturing Challenges for High-Frequency Performance

- What are the benefits of using PTFE gaskets in industrial sealing applications? Achieve Leak-Free Performance in Harsh Environments

- What is the pH range that PTFE Enveloped Gaskets can handle? Achieve Universal Chemical Resistance

- How do PTFE oil scraper rings compare to metal oil scraper rings? Optimize Your Compressor's Performance

- How does PTFE prevent corrosion in piping systems? A Complete Guide to Chemical & Galvanic Protection

- What are the key properties of PTFE that make it suitable for lined bearings? Discover the Ultimate Low-Friction Solution

- What are the properties and applications of glass-filled PTFE bushes? Enhance Strength & Performance