PTFE's exceptional chemical resistance is a cornerstone of its value in industrial settings, directly benefiting applications by preventing equipment degradation, reducing costly downtime, and ensuring operational safety. Its ability to remain stable when exposed to a vast range of aggressive acids, bases, and solvents allows it to protect critical components where other materials would quickly fail.

The core reason for PTFE's industrial advantage is not just resistance, but its fundamental chemical inertness. This non-reactive nature translates directly into tangible benefits: enhanced equipment lifespan, lower long-term operational costs, and unmatched reliability in aggressive environments.

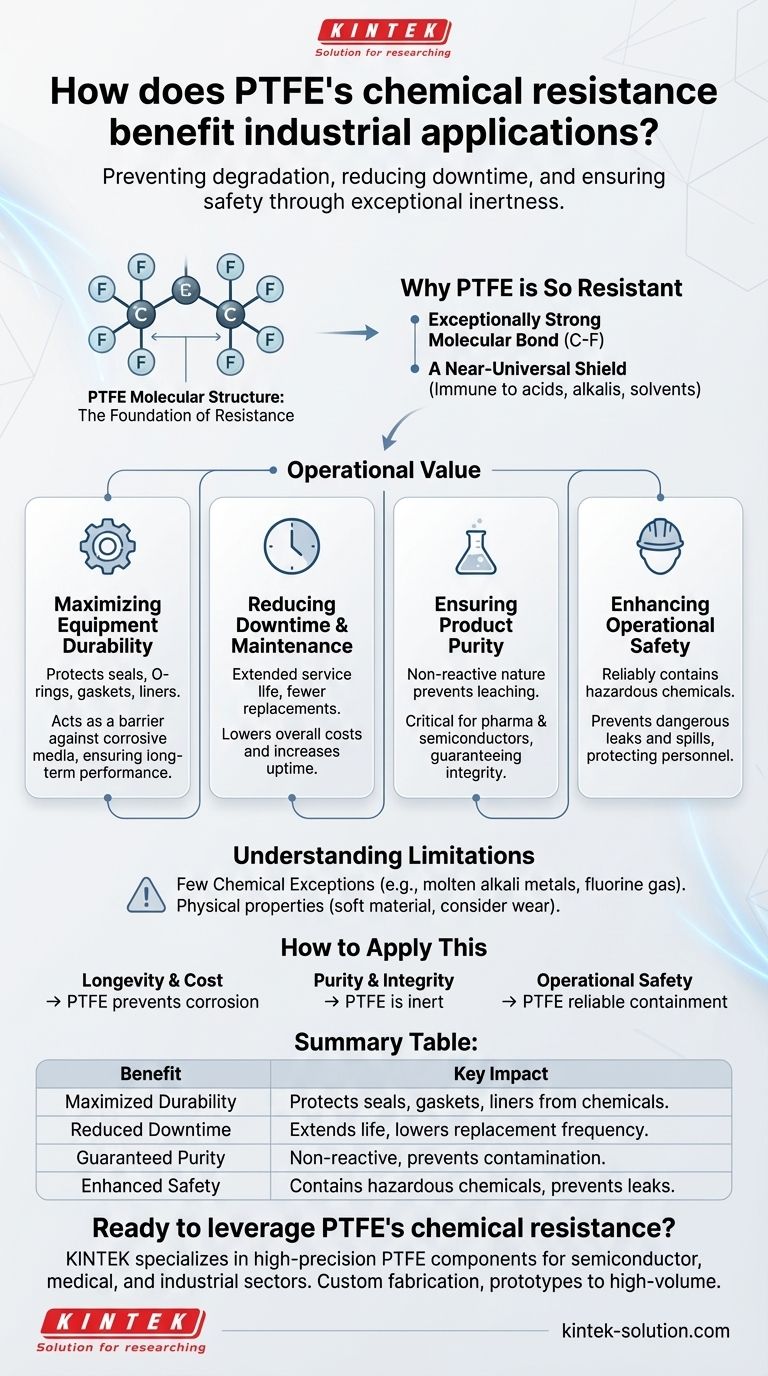

The Foundation: Why PTFE is So Resistant

The benefits of Polytetrafluoroethylene (PTFE) stem from its unique molecular structure, which makes it one of the most non-reactive substances known.

An Exceptionally Strong Molecular Bond

At its core, PTFE consists of a chain of carbon atoms completely shielded by fluorine atoms. The carbon-fluorine bond is one of the strongest in organic chemistry.

This powerful bond makes the molecule incredibly stable and non-reactive, preventing other chemicals from breaking it down or interacting with it.

A Near-Universal Shield

This molecular stability gives PTFE its renowned resistance to an extremely broad spectrum of substances.

It is effectively immune to strong acids, alkalis, alcohols, solvents, oxidants, and other corrosive chemicals that are common in industrial processes.

Translating Resistance into Operational Value

This chemical inertness is not just a theoretical property; it delivers significant, measurable advantages in demanding industrial applications.

Maximizing Equipment Durability

Components like seals, O-rings, gaskets, and pipeline liners made from PTFE act as a barrier against corrosive media.

This protects the larger, more expensive equipment from chemical attack, ensuring long-term durability and consistent performance.

Reducing Downtime and Maintenance Costs

Because PTFE components do not degrade or deteriorate upon chemical exposure, they last significantly longer than parts made from other materials.

This extended service life minimizes the need for frequent replacements, which in turn reduces equipment downtime and lowers overall maintenance costs.

Ensuring Product Purity

In industries like pharmaceuticals and semiconductor manufacturing, preventing contamination is critical.

PTFE's inertness means it will not leach substances into the process fluid or react with the final product, guaranteeing the purity and integrity of sensitive materials.

Enhancing Operational Safety

By reliably containing aggressive and often hazardous chemicals, PTFE components prevent dangerous leaks and spills.

This enhances the safety of personnel and protects the surrounding environment from exposure to corrosive substances.

Understanding the Limitations

While its chemical resistance is nearly absolute, no material is without limitations. An objective assessment requires acknowledging its boundaries.

The Few Chemical Exceptions

PTFE is vulnerable to a very small and specific group of substances under certain conditions.

These include molten alkali metals (like sodium) and highly reactive fluorinating agents, such as fluorine gas at high temperatures. For the vast majority of industrial applications, these exceptions are not a factor.

Physical vs. Chemical Properties

It's important to distinguish chemical resistance from mechanical properties. While chemically robust, PTFE is a relatively soft material.

In high-load or high-abrasion applications, other factors like wear resistance and compressive strength must also be considered.

How to Apply This to Your Application

Choosing a material is about matching its strengths to your primary operational goal.

- If your primary focus is equipment longevity and cost reduction: PTFE's ability to prevent corrosion is your key benefit, directly extending the life of critical components and minimizing replacement cycles.

- If your primary focus is product purity and process integrity: Its inertness makes PTFE the ideal choice for applications where any form of contamination is unacceptable, such as in food-grade or pharmaceutical systems.

- If your primary focus is operational safety: The reliable containment of hazardous chemicals is PTFE's defining feature, providing a trustworthy barrier to protect personnel and the environment.

Ultimately, leveraging PTFE's chemical resistance is a strategic decision to build more robust, reliable, and cost-effective industrial systems.

Summary Table:

| Benefit | Key Impact |

|---|---|

| Maximized Equipment Durability | Protects seals, gaskets, and liners from corrosive chemicals. |

| Reduced Downtime & Maintenance | Extends component life, lowering replacement frequency and costs. |

| Guaranteed Product Purity | Non-reactive nature prevents contamination in sensitive processes. |

| Enhanced Operational Safety | Reliably contains hazardous chemicals to prevent leaks and spills. |

Ready to leverage PTFE's chemical resistance in your application?

At KINTEK, we specialize in manufacturing high-precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your equipment benefits from maximum chemical resistance, extended lifespan, and unwavering reliability.

Whether you need a prototype or a high-volume order, we deliver custom fabrication tailored to your specific requirements.

Contact us today to discuss how our PTFE solutions can enhance your operational efficiency and safety.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key advantages of using PTFE gaskets and sheets? Superior Sealing for Harsh Environments

- What are PTFE lined pipes and where are they used? A Complete Guide to Corrosion-Resistant Piping

- What role does Teflon sheet play in the packaging industry? Ensuring Clean, Non-Stick Heat Sealing

- What are the advantages of using Teflon lip seals? Achieve Unmatched Reliability in Extreme Conditions

- What are the key material characteristics of PTFE that affect its CNC machining? Master Precision for Soft, Slippery Materials

- What are the key characteristics of PTFE oil seals? Unlock Superior Performance in Extreme Conditions

- What are the key properties of PTFE oil seals? Superior Performance for Extreme Environments

- What are the key roles of gland packing in industrial applications? Achieve Robust, Controllable Sealing