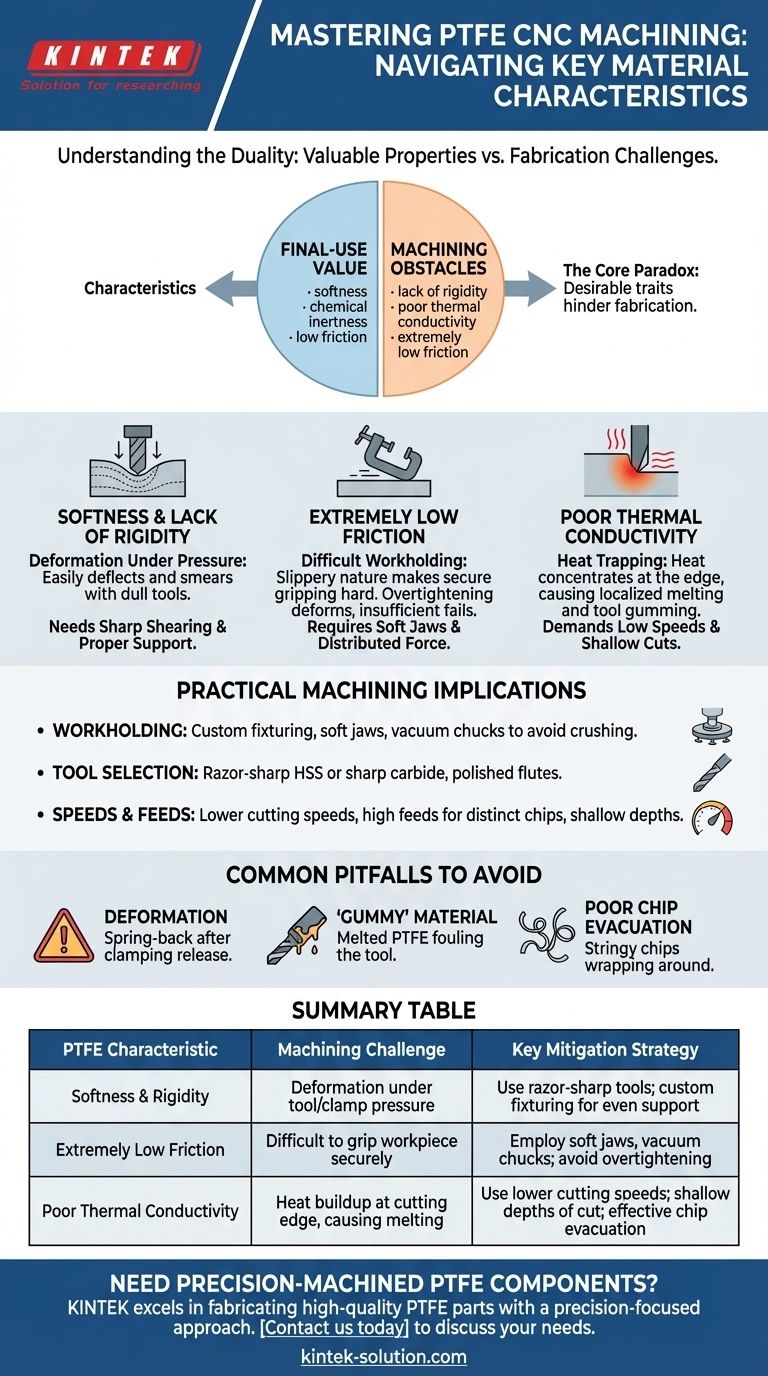

At its core, CNC machining of PTFE is governed by a central paradox: its most valuable final-use properties—softness, chemical inertness, and a low-friction surface—are the very characteristics that present the greatest challenges during fabrication. The key material properties affecting its machining are its lack of rigidity, which leads to deformation under pressure, its poor thermal conductivity, which traps heat at the cutting edge, and its extremely low coefficient of friction, which makes secure workholding difficult.

The fundamental challenge in machining PTFE is not cutting it, but controlling it. Success depends on techniques that manage material deformation and localized heat buildup, which are direct consequences of the material's inherent softness and poor thermal dissipation.

The Duality of PTFE's Core Properties

PTFE is often chosen for its unique combination of characteristics. However, for a machinist, these same traits must be understood as potential obstacles to precision.

Softness and Lack of Rigidity

PTFE is a soft material that lacks structural stiffness. It easily deflects under the pressure of a cutting tool or clamping force.

This softness means tools must be exceptionally sharp to shear the material cleanly rather than pushing it, which would cause it to deform, tear, or "smear" instead of cutting.

Without proper support, the material can also vibrate or "chatter" during machining, resulting in poor surface finish and inaccurate dimensions.

Extremely Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any solid, making it incredibly "slippery." This is excellent for applications like non-stick coatings and low-friction bearings.

During machining, however, this property makes it difficult to grip the workpiece securely. Overtightening a clamp will deform the soft material, while insufficient pressure will allow the part to shift or spin.

Thermal Characteristics

PTFE has a very high melting point (327°C) and excellent continuous service temperature (260°C), making it stable in hot environments.

Crucially, however, it is a poor thermal conductor. Heat generated by the friction of the cutting tool does not dissipate quickly through the material. This heat becomes concentrated at the cutting edge, which can cause localized melting, tool gumming, and part warping, even at temperatures well below its overall melting point.

Practical Machining Implications

Understanding these properties directly informs the strategy for successfully machining PTFE components. A specialized approach is non-negotiable.

Workholding is the Primary Challenge

Securing the PTFE stock without distortion is the first and most critical step. Standard vise jaws with high clamping pressure will crush the material.

Custom fixturing, soft jaws, or vacuum chucks are often necessary to distribute clamping force evenly and hold the part securely with minimal pressure.

Tool Selection and Geometry

Tools must be razor-sharp. Any dullness will increase cutting forces, leading to material deformation and heat generation.

High-speed steel (HSS) or uncoated, sharp-edged carbide tools are often recommended. Polished flutes help prevent the "gummy" chips from sticking to the tool.

Speeds, Feeds, and Depth of Cut

A counter-intuitive approach is required. To manage heat, lower cutting speeds are used. This reduces the friction and energy introduced into the part.

Feed rates must be high enough to produce a distinct chip and avoid rubbing, but not so high that they exert excessive force. Shallow depths of cut are essential to minimize heat accumulation and cutting pressure.

Common Pitfalls to Avoid

Ignoring PTFE's unique nature leads to predictable failures. Awareness of these common issues is key to preventing them.

Deformation Under Clamping Pressure

This is the most frequent unforced error. A machinist may secure a PTFE billet in a vise, and the part may appear perfectly dimensioned while clamped. Once released, however, the material springs back, revealing it was compressed and is now out of tolerance.

The "Gummy" Material Problem

When too much heat is generated, the PTFE at the cutting edge doesn't form a clean chip. Instead, it becomes soft and sticky, fouling the cutting tool. This ruins the surface finish and can quickly lead to catastrophic tool failure.

Poor Chip Evacuation

PTFE produces continuous, stringy chips. If not managed properly, these chips can wrap around the tool and workpiece, melting onto the surface and marring the finish. Effective chip removal, often with compressed air, is vital.

Making the Right Choice for Your Process

Your machining strategy should be tailored to the specific requirements of the final component.

- If your primary focus is precision and tight tolerances: Prioritize sharp tooling, minimal and evenly distributed clamping force, and very light finishing passes.

- If your primary focus is excellent surface finish: Concentrate on managing heat by using lower cutting speeds, sharp tools, and effective chip evacuation to prevent any localized melting.

- If your primary focus is high-volume production: Invest in custom fixturing that allows for quick, repeatable, and secure workholding without causing material deformation.

Ultimately, treating PTFE as a unique material requiring finesse over force is the key to producing high-quality, dimensionally accurate components.

Summary Table:

| PTFE Characteristic | Machining Challenge | Key Mitigation Strategy |

|---|---|---|

| Softness & Lack of Rigidity | Deformation under tool/clamp pressure | Use razor-sharp tools; custom fixturing for even support |

| Extremely Low Friction | Difficult to grip workpiece securely | Employ soft jaws, vacuum chucks; avoid overtightening |

| Poor Thermal Conductivity | Heat buildup at cutting edge, causing melting | Use lower cutting speeds; shallow depths of cut; effective chip evacuation |

Need precision-machined PTFE components?

Machining PTFE requires specialized expertise to overcome its unique challenges. At KINTEK, we excel in fabricating high-quality PTFE parts (seals, liners, labware, and more) for the semiconductor, medical, laboratory, and industrial sectors. Our precision-focused approach ensures your components meet exact specifications, from prototypes to high-volume production.

Contact us today to discuss your PTFE machining needs and benefit from our technical expertise!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts