At their core, PTFE oil seals are defined by their exceptional resistance to heat, chemicals, and friction. This unique combination allows them to perform reliably in demanding operational environments where conventional seals would quickly degrade. They can withstand temperatures up to 260°C (500°F), resist aggressive fluids like acids and solvents, and can even function effectively with little to no lubrication.

PTFE seals are not a universal replacement for standard seals, but a high-performance solution engineered for specific, challenging environments. Their primary value is ensuring operational reliability and extending service life where extreme heat, aggressive chemicals, or a lack of lubrication would cause conventional seals to fail.

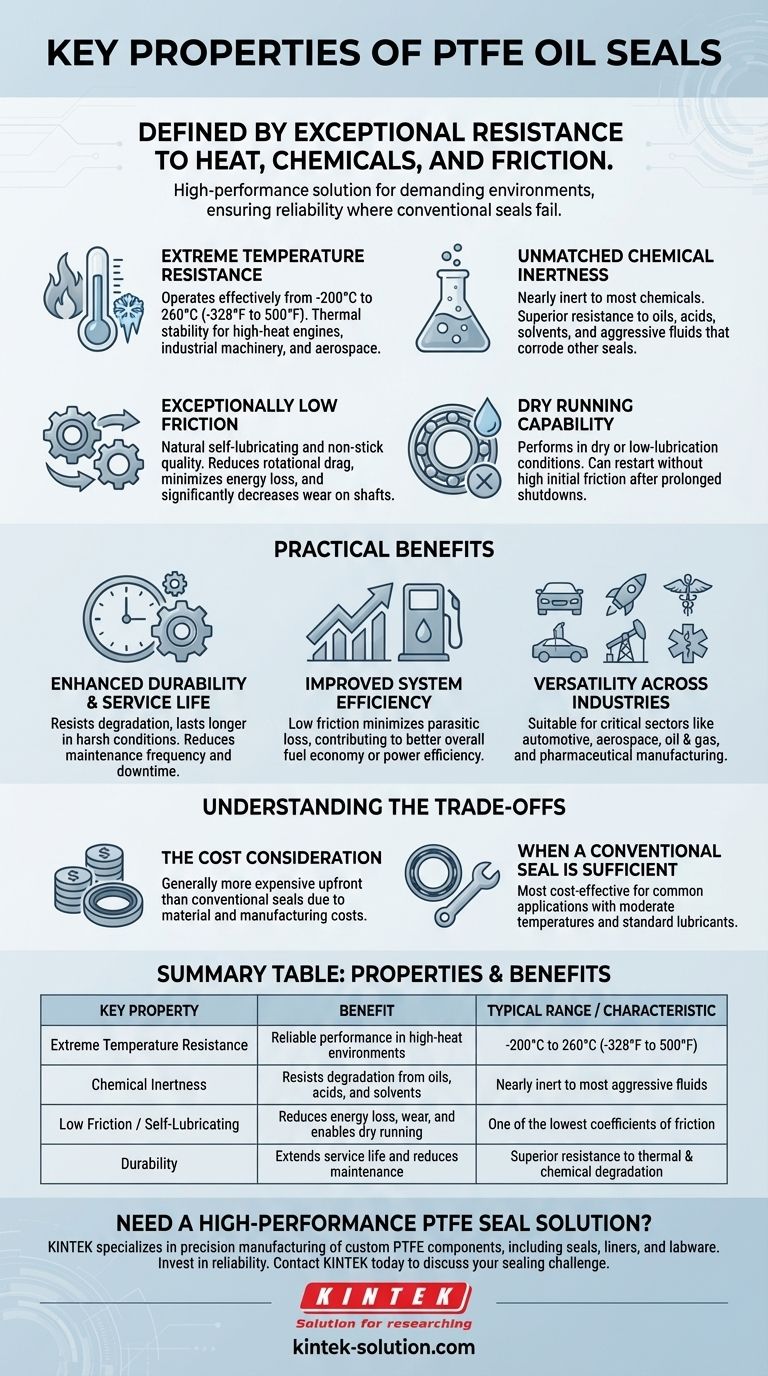

The Core Properties That Define PTFE Seals

To understand their value, we must break down the distinct material characteristics of Polytetrafluoroethylene (PTFE) that set these seals apart from traditional alternatives.

Extreme Temperature Resistance

PTFE seals operate effectively across an exceptionally wide temperature range, typically from -200°C to 260°C (-328°F to 500°F). This thermal stability makes them indispensable in applications involving high-heat engines, industrial machinery, and aerospace systems.

Unmatched Chemical Inertness

The material is nearly inert, meaning it does not react with most chemicals. This gives PTFE seals superior resistance to oils, acids, solvents, and other aggressive fluids that would corrode or swell conventional rubber seals.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, giving it a natural self-lubricating and non-stick quality. This property reduces rotational drag, minimizes energy loss, and significantly decreases wear on the shaft.

Dry Running Capability

A direct result of its low-friction nature is the ability to perform in dry or low-lubrication conditions. Even after a prolonged shutdown, a PTFE seal can restart without the high initial friction that can damage other seal types.

The Practical Benefits in Demanding Applications

These fundamental properties translate directly into tangible performance advantages, making PTFE seals a strategic choice for improving system reliability and reducing long-term costs.

Enhanced Durability and Service Life

By resisting thermal and chemical degradation, PTFE seals last significantly longer in harsh operating conditions. This durability reduces the frequency of maintenance and equipment downtime.

Improved System Efficiency

The low-friction surface minimizes the energy required to turn the shaft. This reduction in parasitic loss contributes to better overall fuel economy or power efficiency in the system.

Versatility Across Industries

The unique combination of properties makes PTFE seals suitable for a wide range of critical sectors, including automotive, aerospace, oil and gas, and pharmaceutical manufacturing, where performance cannot be compromised.

Understanding the Trade-offs

While PTFE seals offer superior performance in specific contexts, they are not the default choice for every application. Objectivity requires acknowledging their primary trade-off.

The Cost Consideration

PTFE seals are generally more expensive upfront than their conventional rubber or elastomer counterparts. The manufacturing process and raw material costs are higher.

When a Conventional Seal is Sufficient

For many common applications with moderate temperatures, standard lubricants, and no aggressive chemicals, a conventional seal remains the most cost-effective solution. They perform well in these environments without the added expense of a high-performance material.

Making the Right Choice for Your Application

Selecting the correct seal is an engineering decision that balances performance requirements with budget constraints. Your primary goal should guide your choice.

- If your primary focus is reliability in extreme temperatures or with aggressive chemicals: PTFE seals are the definitive choice, as their material properties are engineered specifically for these conditions.

- If your primary focus is reducing friction and enabling dry-run capability: The self-lubricating nature of PTFE provides a significant operational advantage over seals that require constant lubrication.

- If your primary focus is cost-effectiveness for a standard application: A conventional elastomer seal is likely the more economical and perfectly adequate solution.

Ultimately, selecting a PTFE seal is an investment in long-term reliability for your most critical and demanding sealing challenges.

Summary Table:

| Key Property | Benefit | Typical Range/Characteristic |

|---|---|---|

| Extreme Temperature Resistance | Reliable performance in high-heat environments | -200°C to 260°C (-328°F to 500°F) |

| Chemical Inertness | Resists degradation from oils, acids, and solvents | Nearly inert to most aggressive fluids |

| Low Friction / Self-Lubricating | Reduces energy loss, wear, and enables dry running | One of the lowest coefficients of friction |

| Durability | Extends service life and reduces maintenance in harsh conditions | Superior resistance to thermal and chemical degradation |

Need a High-Performance PTFE Seal Solution?

Your most demanding applications require seals that won't fail under pressure, heat, or aggressive chemicals. The unique properties of PTFE make it the ideal material for extreme environments in the semiconductor, medical, laboratory, and industrial sectors.

KINTEK specializes in the precision manufacturing of custom PTFE components, including seals, liners, and labware. We partner with you from prototype to high-volume production to deliver reliable solutions that enhance operational efficiency and extend equipment service life.

Invest in reliability. Contact KINTEK today to discuss your specific sealing challenge and receive a quote.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What types of components are commonly manufactured from PTFE? Seals, Bearings, Insulators & More

- What are PTFE washers made of? Unlocking the Power of Carbon-Fluorine Chemistry

- Can PTFE rods be machined into complex shapes? Yes, with precision engineering for custom parts.

- What types of fluids can PTFE control valves handle? Master Corrosive Chemicals with Confidence

- What factors should be considered when selecting PTFE seals? Ensure Perfect Sealing for Your Critical Applications

- What are the main advantages of using Teflon gland packing? Achieve Superior Sealing and Lower Costs

- What precautions should be taken during the installation of PTFE gasket seals? Ensure a Perfect, Leak-Free Seal

- What methods are used to apply PTFE coatings to fasteners? Dip vs. Spray Coating Explained