Properly installing a PTFE gasket seal is a meticulous process that demands more than just physical placement. The key precautions involve careful handling to protect sealing surfaces, ensuring absolute cleanliness of all components, applying force gradually and symmetrically with proper tools, and avoiding over-tightening which can permanently deform the soft material and compromise the seal.

Successful PTFE gasket installation hinges on respecting the material's unique properties. Because PTFE is soft and prone to deformation, precision, cleanliness, and controlled force are non-negotiable to prevent creating invisible leak paths from the very start.

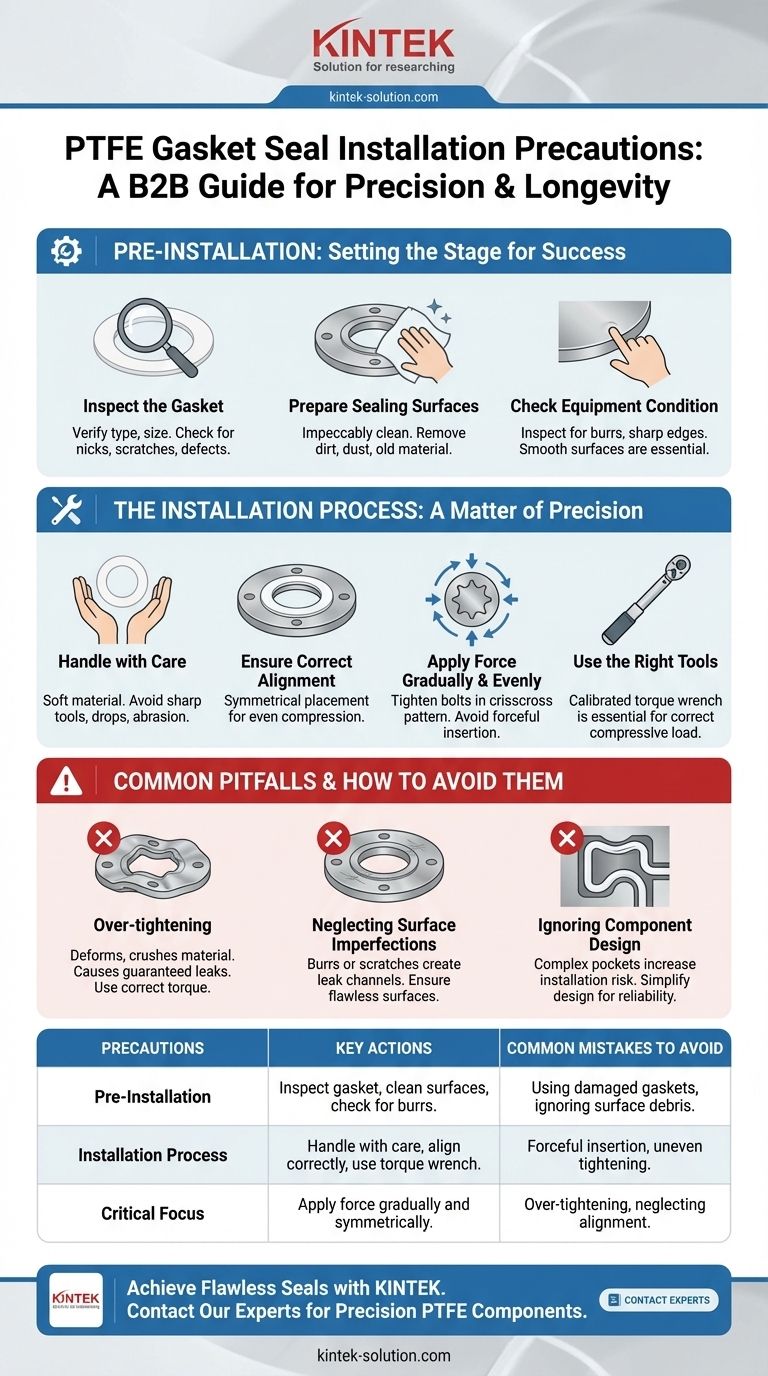

Pre-Installation: Setting the Stage for Success

The most common installation failures originate from a lack of preparation. Ensuring the components are ready before the gasket is even handled is the first and most critical phase.

Inspect the Gasket Itself

Before you begin, thoroughly inspect the new PTFE gasket. Confirm it is the correct type and size for the application and check for any nicks, scratches, or manufacturing defects that could compromise its integrity.

Prepare the Sealing Surfaces

The flange faces or sealing surfaces must be impeccably clean. Remove all dirt, dust, and old gasket material. Even microscopic debris can create a significant leak path under pressure.

Check the Equipment Condition

Inspect the gland and mating surfaces for any burrs or sharp edges. These imperfections can easily damage the soft PTFE material during installation, leading to immediate or premature failure. Smooth surfaces are essential.

The Installation Process: A Matter of Precision

The physical act of installation requires a delicate and methodical approach. Rushing this stage is a primary cause of seal failure.

Handle with Care

PTFE is a relatively soft material. Avoid dropping the gasket or allowing it to come into contact with sharp tools or abrasive surfaces. Protect the sealing line and any raised surfaces at all costs.

Ensure Correct Alignment

Place the gasket carefully onto the sealing surface. Proper symmetry and balance are critical to ensure even compression across the entire face of the seal, preventing localized pressure points that can lead to leaks.

Apply Force Gradually and Evenly

Never use forceful insertion. Tighten bolts in a star or crisscross pattern to apply pressure evenly. This gradual process prevents the gasket from being pinched or unevenly compressed.

Use the Right Tools

Using a calibrated torque wrench is not optional; it is essential. It is the only way to ensure you achieve the required compressive load without exceeding the material's limits.

Common Pitfalls and How to Avoid Them

Understanding what can go wrong provides the insight needed to ensure everything goes right. These common mistakes are easily avoidable with the right knowledge.

The Danger of Over-tightening

This is the single most common installation error. Excessive force will deform, crush, or extrude the soft PTFE material out of the joint. This permanently damages the gasket's structure and guarantees a leak.

Neglecting Surface Imperfections

A perfectly installed gasket will still fail if placed on a flawed surface. A small burr or scratch on a flange face creates a built-in channel for fluid or gas to escape.

Ignoring Component Design

The design of the sealing pocket or cavity itself matters. Complex machined pockets that require the seal to be twisted or bent significantly increase the risk of damage during installation. Proper design simplifies the process and improves reliability.

Making the Right Choice for Your Goal

Your installation focus should align with the demands of your specific application.

- If your primary focus is maximizing seal lifespan: Prioritize meticulous surface preparation and the consistent use of a calibrated torque wrench to prevent material deformation.

- If your primary focus is preventing micro-leaks in critical systems: Pay extreme attention to the symmetrical alignment and gradual, even tightening of the fasteners.

- If your primary focus is ease of maintenance: Ensure the equipment gland and sealing cavities are well-designed and free of burrs to facilitate simple installation without damaging the seal.

A successful seal is the direct result of precision and a thorough understanding of the material's properties before, during, and after installation.

Summary Table:

| Precautions | Key Actions | Common Mistakes to Avoid |

|---|---|---|

| Pre-Installation | Inspect gasket, clean surfaces, check for burrs | Using damaged gaskets, ignoring surface debris |

| Installation Process | Handle with care, align correctly, use torque wrench | Forceful insertion, uneven tightening |

| Critical Focus | Apply force gradually and symmetrically | Over-tightening, neglecting alignment |

Need a reliable PTFE gasket that installs perfectly every time?

At KINTEK, we understand that a successful seal starts with precision manufacturing. Our PTFE components—including seals, liners, and labware—are crafted for exacting applications in semiconductor, medical, laboratory, and industrial settings. We prioritize dimensional accuracy and material integrity to ensure your installation is straightforward and leak-free from the start.

Whether you need standard parts or custom fabrication from prototypes to high-volume orders, we deliver solutions that match your specific requirements.

Let us help you achieve a flawless seal. Contact our experts today to discuss your project needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the main features of PTFE bellow mechanical seals? A Guide to Extreme Chemical Resistance and Reliability

- In which industries are machined PTFE parts commonly used? Discover the Essential High-Performance Material

- How do PTFE lip seals compare to traditional elastomer lip seals? A Guide to High-Performance Sealing

- What are the characteristics of fully PFA or PTFE lined butterfly valves? Maximize Corrosion Resistance & Reliability

- What are the properties of stainless steel-filled PTFE bushings? Achieve Superior Strength & Durability

- What is the radiation resistance of PTFE and mPTFE? Key Insights for Semiconductor & Medical Applications

- How do PEEK and POM compare in terms of pressure resistance? A Guide for High-Performance Applications

- What are the technical advantages of PTFE slide bearings? Achieve Maintenance-Free, Long-Lasting Structural Movement