Selecting the right PTFE seal requires a systematic evaluation of four primary factors: the material composition (pure vs. filled PTFE), the physical seal design, the specific operating conditions it will face, and the characteristics of the hardware it will be installed into. A mismatch in any of these areas can lead to premature failure, leaks, and costly downtime.

The optimal PTFE seal is not an off-the-shelf component but the result of a deliberate design choice. True reliability comes from viewing the seal not in isolation, but as a critical part of an integrated system where its material, design, and operating environment are perfectly aligned.

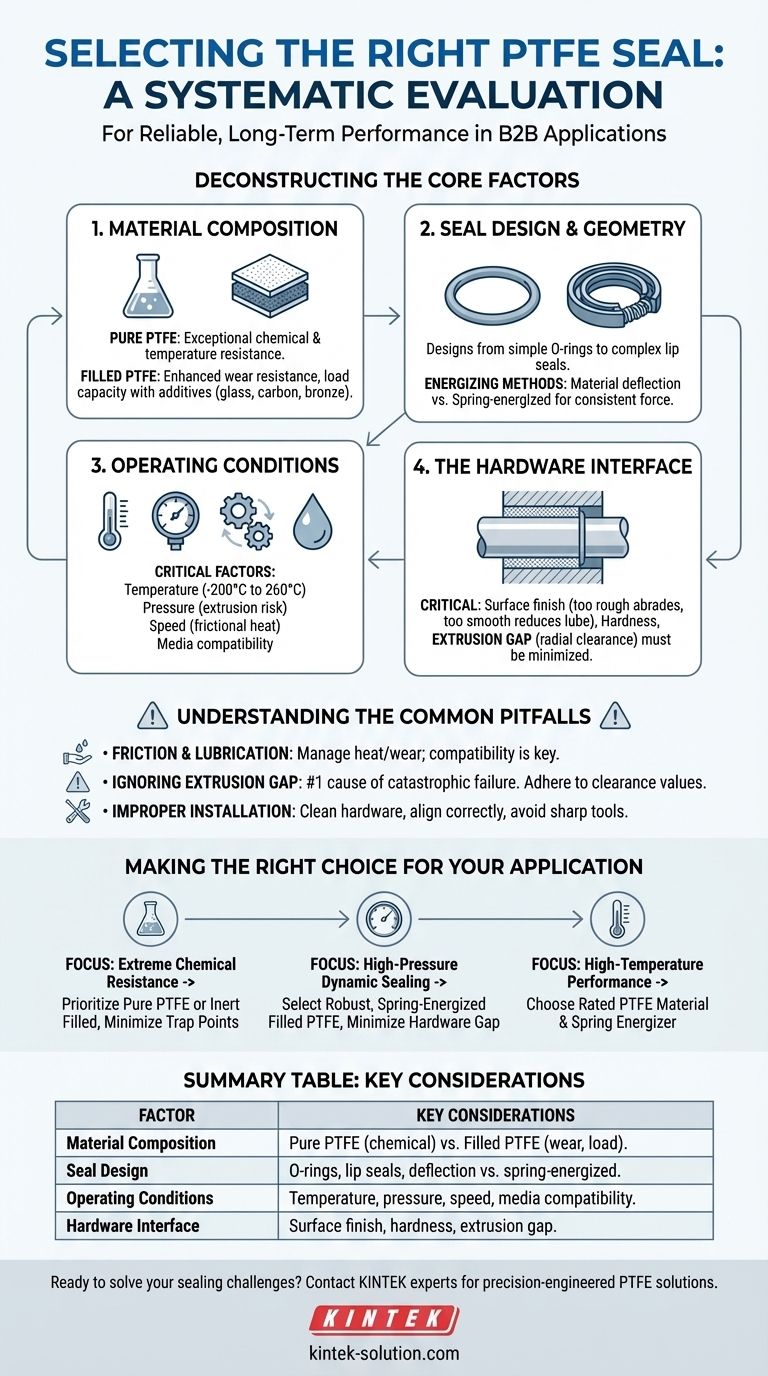

Deconstructing the Core Factors

To ensure long-term performance, each aspect of the seal and its environment must be carefully analyzed. The interplay between these factors determines the success or failure of the application.

Material Composition: Pure vs. Filled PTFE

The foundation of any seal is its material. Pure PTFE offers exceptional chemical and temperature resistance, making it ideal for environments with aggressive media.

For more demanding mechanical applications, filled PTFE is the superior choice. Additives like glass, carbon, or bronze are blended into the PTFE to significantly enhance properties like wear resistance, load-bearing capacity, and resistance to deformation under pressure.

Seal Design and Geometry

The physical shape of the seal is dictated by the application's demands. Designs range from simple O-rings to complex, multi-component lip seals.

A key design consideration is the energizing method. Some seals rely on their material's own elasticity (deflection systems), while others use a metal spring (spring-energized systems) to provide a consistent sealing force across a wide range of temperatures and pressures.

Operating Conditions: The Non-Negotiables

This is the most critical area of analysis, as the environment will constantly challenge the seal.

- Temperature: PTFE has a wide operating range (typically -200°C to 260°C), but extreme temperatures can affect material hardness and sealing force.

- Pressure: High pressure can cause the seal material to extrude into gaps. The seal's material and design must be robust enough to resist this.

- Speed: In dynamic applications, high speeds generate frictional heat, which can degrade the seal material over time.

- Media: The seal must be chemically compatible with all fluids or gases it will contact to prevent swelling, degradation, or chemical attack.

The Hardware Interface: Where the Seal Meets the Machine

A perfect seal can fail if the hardware is not properly prepared. The two are inextricably linked.

Surface finish is critical; a surface that is too rough will abrade the seal lip, while a surface that is too smooth may not provide adequate lubrication retention.

Likewise, the hardness of the mating hardware surface must be sufficient to prevent wear. Most importantly, the extrusion gap (or radial clearance) between moving parts must be minimized to support the seal and prevent it from being physically pushed out of place under high pressure.

Understanding the Common Pitfalls

Selecting a seal is only half the battle. Avoiding common mistakes during implementation is essential for achieving a reliable seal.

The Friction and Lubrication Balance

While PTFE is known for its low friction, this property can be affected by high loads, speeds, and temperatures. In some cases, lubrication is still necessary to dissipate heat and minimize wear, and its compatibility with the seal material is non-negotiable.

Ignoring the Extrusioin Gap

This is one of the most common causes of catastrophic seal failure. If the clearance between the rod and the bore is too large, high pressure will physically force the softer PTFE material into the gap, destroying the seal. Always adhere to the manufacturer's recommended clearance values for the given pressure.

Installation: The Final, Critical Step

The most advanced seal in the world will fail if installed improperly. Using sharp tools that can nick the seal lip, failing to clean the hardware of debris, or applying uneven force can all create an immediate leak path. Correct alignment and the use of proper installation tools are paramount.

Making the Right Choice for Your Application

Your final decision should be guided by the primary demand of your specific application.

- If your primary focus is extreme chemical resistance: Prioritize pure PTFE or a chemically inert filled PTFE, ensuring the seal design minimizes potential trap points for media.

- If your primary focus is high-pressure dynamic sealing: Select a robust, spring-energized design made from a filled PTFE compound engineered for wear resistance, and pay strict attention to minimizing the hardware's extrusion gap.

- If your primary focus is high-temperature performance: Choose a PTFE material and spring energizer (if applicable) specifically rated for your target temperature range to prevent loss of sealing force.

Ultimately, a successful sealing solution is achieved by methodically matching the seal's capabilities to the precise demands of the system it serves.

Summary Table:

| Factor | Key Considerations |

|---|---|

| Material Composition | Pure PTFE (chemical resistance) vs. Filled PTFE (wear resistance, load capacity) |

| Seal Design | O-rings, lip seals, deflection systems, or spring-energized systems |

| Operating Conditions | Temperature, pressure, speed, and media compatibility |

| Hardware Interface | Surface finish, hardness, and extrusion gap (radial clearance) |

Ready to solve your sealing challenges with precision-engineered PTFE components?

At KINTEK, we don't just sell seals; we deliver reliable sealing solutions. Our expertise in custom PTFE fabrication ensures your seals are perfectly matched to your application's unique demands—whether you're in the semiconductor, medical, laboratory, or industrial sector.

We partner with you to:

- Optimize Performance: Select the ideal material (pure or filled PTFE) and design for your specific temperature, pressure, and chemical environment.

- Prevent Failures: Engineer solutions that account for critical factors like extrusion gaps and hardware compatibility to avoid costly downtime.

- Scale with You: From initial prototypes to high-volume production, we provide consistent quality and support.

Let's engineer your solution together. Contact our experts today for a consultation.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key properties of PTFE that make it suitable for sealing applications? | High-Performance Seals for Extreme Conditions

- What is the overall operating temperature range for PTFE seals, gaskets, and O-rings? Achieve Sealing Integrity from -200°C to +260°C

- What are the key advantages of PTFE rotary seals over traditional rubber seals? Superior Performance in Extreme Conditions

- What are the two temperature extremes discussed for PTFE seals? Maximize Performance from Cryogenic to High-Heat

- How do FEP and PTFE encapsulated O-rings contribute to equipment longevity? Prevent Costly Downtime with Superior Seals