Polytetrafluoroethylene (PTFE) is a uniquely versatile fluoropolymer used to manufacture a wide range of high-performance components. Due to its exceptional properties, it is most commonly used for parts requiring extreme chemical resistance, low friction, or high-temperature electrical insulation. This includes components like seals, gaskets, O-rings, bearings, bushings, and insulators for demanding industrial applications.

The decision to specify a component made from PTFE is almost always driven by its core characteristics: its extreme chemical inertness, its incredibly low coefficient of friction, its wide operating temperature range, or its excellent dielectric properties.

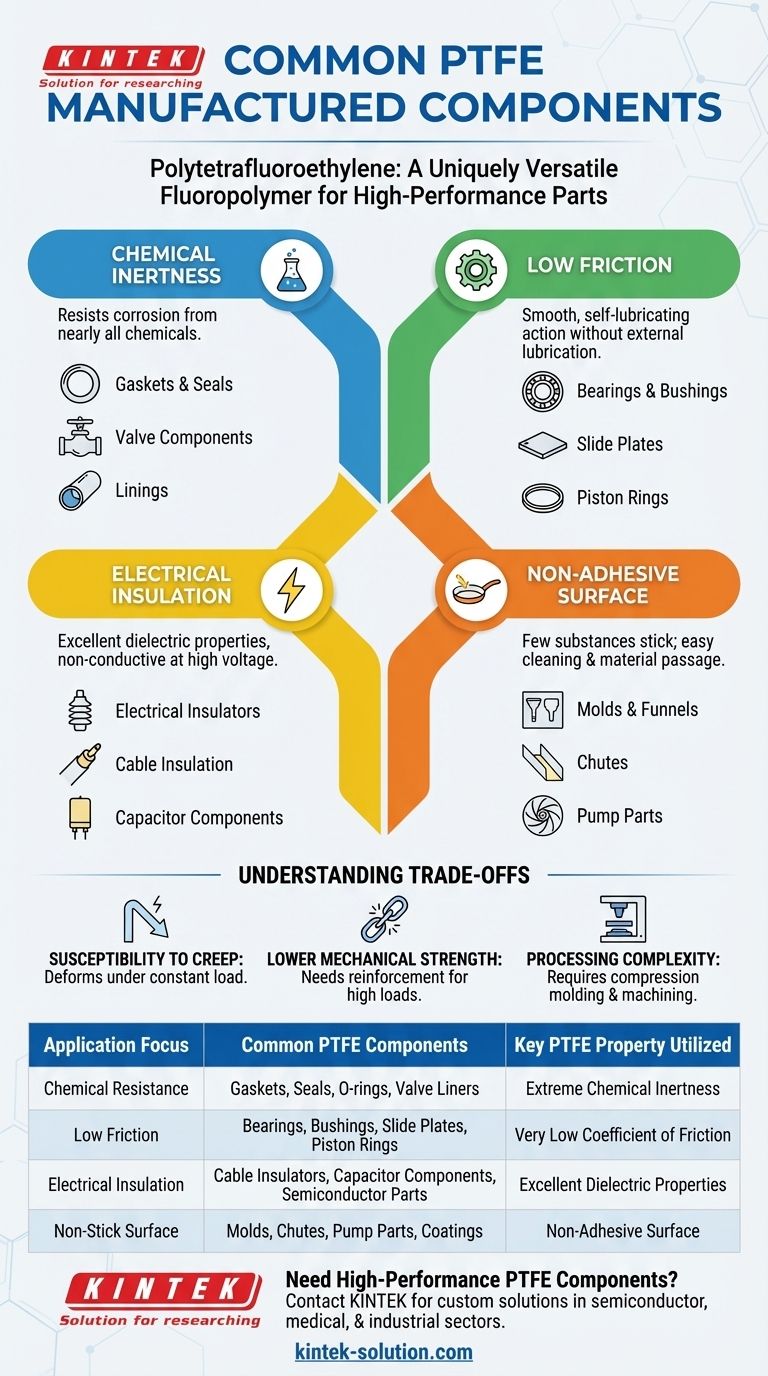

Why PTFE is a Premier Engineering Material

PTFE, widely known by the brand name Teflon®, is not a single-use material. Its value comes from a combination of properties that are difficult to find in any other polymer. Understanding these traits is key to understanding its applications.

The Impact of Chemical Inertness

PTFE is non-reactive to nearly all chemicals and solvents. This makes it an essential material for components that will be exposed to corrosive or aggressive substances.

Common components in this category include gaskets, seals, O-rings, V-rings, valve components, and linings for pipework and chemical containers.

The Advantage of Low Friction

With one of the lowest coefficients of friction of any solid material, PTFE is ideal for applications where smooth, sliding action is required without external lubrication.

This property leads to its use in bearings, bushings, slide plates, gears, piston rings, and non-stick surface coatings.

The Importance of Electrical Insulation

PTFE has excellent dielectric properties, meaning it does not conduct electricity and can withstand high voltages. This makes it a superior insulator, especially for high-frequency applications.

Typical components include electrical insulators, insulation for coaxial cables and hookup wires, and components for capacitors and semiconductors.

The Benefit of a Non-Adhesive Surface

Few substances will stick to a PTFE surface. This non-stick characteristic is invaluable for components that must remain clean or allow other materials to pass over them easily.

This leads to its use in molds, funnels, chutes, pump parts, and as a coating for cookware and industrial processing equipment.

Understanding the Trade-offs

While its properties are exceptional, PTFE is not the solution for every engineering problem. Its limitations are just as important to understand as its strengths to avoid misapplication.

Susceptibility to Creep

PTFE is a relatively soft material and can be subject to "creep" or cold flow. This means it can slowly deform over time if placed under a constant, heavy load, particularly at elevated temperatures.

Lower Mechanical Strength

Compared to other engineering plastics like nylon or PEEK, PTFE has lower tensile strength and wear resistance. It is not typically suitable for high-load structural components unless it is reinforced with fillers like glass fiber or carbon.

Processing Complexity

PTFE cannot be processed using conventional melt techniques like injection molding. It is most often compression molded into basic shapes (like rods or sheets) and then precisely machined into the final component.

Making the Right Choice for Your Application

Selecting the correct material requires matching the primary challenge of your application to the core strength of the material.

- If your primary focus is sealing against aggressive chemicals: PTFE's unrivaled chemical inertness makes it the default choice for gaskets, seals, and valve components.

- If your primary focus is reducing friction and wear: Its self-lubricating nature is ideal for creating maintenance-free bearings, bushings, and slide plates.

- If your primary focus is electrical insulation: PTFE's excellent dielectric properties are essential for high-frequency components like cable insulators and capacitors.

- If your primary focus is a non-stick surface: Its non-adhesive quality is perfect for molds, material handling chutes, and specialized coatings.

Ultimately, understanding these core properties is the key to identifying where PTFE will deliver unparalleled performance in your design.

Summary Table:

| Application Focus | Common PTFE Components | Key PTFE Property Utilized |

|---|---|---|

| Chemical Resistance | Gaskets, Seals, O-rings, Valve Liners | Extreme Chemical Inertness |

| Low Friction | Bearings, Bushings, Slide Plates, Piston Rings | Very Low Coefficient of Friction |

| Electrical Insulation | Cable Insulators, Capacitor Components, Semiconductor Parts | Excellent Dielectric Properties |

| Non-Stick Surface | Molds, Chutes, Pump Parts, Coatings | Non-Adhesive Surface |

Need High-Performance PTFE Components for Your Project?

At KINTEK, we specialize in manufacturing precision PTFE components—from custom seals and liners to complex labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume production, our expertise ensures components that meet your exact specifications for chemical resistance, low friction, and electrical insulation.

Let us help you solve your toughest engineering challenges. Contact our team today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F