To put it simply, PTFE control valves are specifically engineered to handle the most aggressive and corrosive fluids. Their primary application is in services involving harsh chemicals like acids, caustic soda (sodium hydroxide), chlorine, and a wide variety of industrial plating solutions where standard materials would quickly fail.

The core reason to select a PTFE control valve is its exceptional chemical inertness. It is not a general-purpose valve; it is a specialized solution designed to provide long-term reliability in highly corrosive environments that would destroy most other materials.

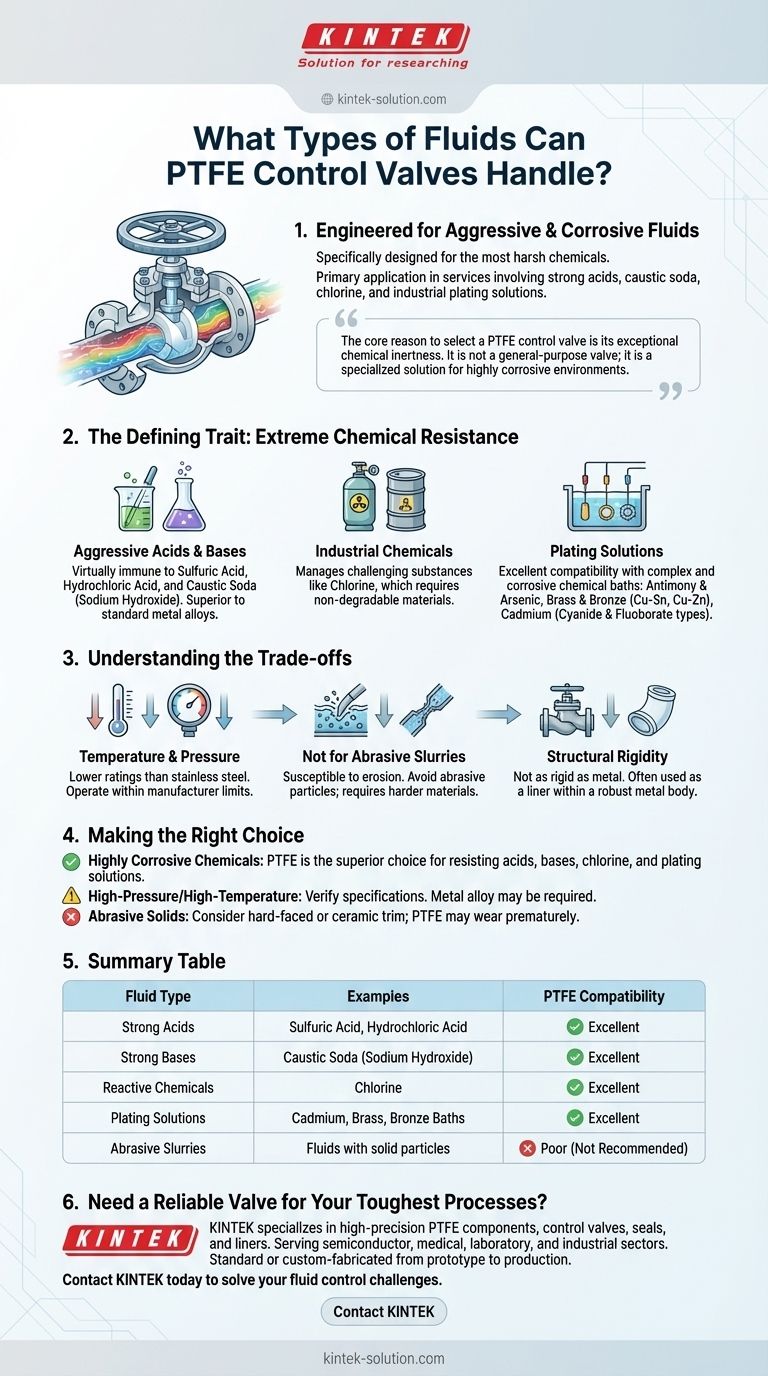

The Defining Trait of PTFE: Extreme Chemical Resistance

Polytetrafluoroethylene (PTFE) is a fluoropolymer with incredibly strong carbon-fluorine bonds, making it one of the most non-reactive substances known. This unique chemical structure is the key to its performance in control valves.

Handling Aggressive Acids and Bases

PTFE is virtually immune to attack from strong acids and alkaline solutions. This makes it an ideal choice for controlling substances like sulfuric acid, hydrochloric acid, and caustic soda, which are known to rapidly corrode even specialized metal alloys.

Compatibility with Industrial Chemicals

Beyond simple acids and bases, PTFE valves are used to manage other challenging chemicals. A common example is chlorine, which is highly reactive and requires materials that will not degrade upon exposure.

Specialized Use in Plating Solutions

The material shows excellent compatibility in various electroplating processes, which often involve complex and corrosive chemical baths. PTFE valves reliably handle fluids such as:

- Antimony and arsenic plating solutions

- Brass and bronze plating baths (Cu-Sn, Cu-Zn)

- Cadmium plating baths (both cyanide and fluoborate types)

Understanding the Trade-offs

While its chemical resistance is nearly unmatched, choosing a PTFE valve involves understanding its physical limitations compared to metal alternatives.

Temperature and Pressure

PTFE has lower temperature and pressure ratings than stainless steel or other high-performance alloys. It is crucial to operate within the manufacturer's specified limits to prevent mechanical failure, even if the chemical compatibility is perfect.

Not for Abrasive Slurries

PTFE is a relatively soft material. While ideal for corrosive liquids and gases, it can be susceptible to erosion and damage from abrasive particles in a fluid stream. Abrasive slurries often require valves with harder lining materials.

Structural Rigidity

As a polymer, PTFE is not as rigid as metal. In valve design, this means it is often used as a liner or for wetted components within a more robust metal body, combining the structural strength of metal with the chemical resistance of PTFE.

Making the Right Choice for Your Application

Selecting the correct valve material is critical for safety, reliability, and cost-effectiveness.

- If your primary focus is handling highly corrosive chemicals: A PTFE valve is almost always the superior choice for its ability to resist acids, bases, chlorine, and complex plating solutions without degrading.

- If your primary focus is high-pressure or high-temperature service: You must carefully verify the valve's specifications, as a metal alloy valve may be required to meet the demanding physical conditions.

- If your primary focus is controlling fluids with abrasive solids: Consider a valve with a hard-faced or ceramic trim, as the softness of PTFE may lead to premature wear.

Ultimately, selecting a PTFE control valve is a strategic decision for safely and reliably managing the most chemically aggressive fluids in your system.

Summary Table:

| Fluid Type | Examples | PTFE Compatibility |

|---|---|---|

| Strong Acids | Sulfuric Acid, Hydrochloric Acid | Excellent |

| Strong Bases | Caustic Soda (Sodium Hydroxide) | Excellent |

| Reactive Chemicals | Chlorine | Excellent |

| Plating Solutions | Cadmium, Brass, Bronze Baths | Excellent |

| Abrasive Slurries | Fluids with solid particles | Poor (Not Recommended) |

Need a reliable valve for your most aggressive chemical processes?

KINTEK specializes in manufacturing high-precision PTFE components, including control valves, seals, and liners. We serve the semiconductor, medical, laboratory, and industrial sectors by providing durable, chemically inert solutions that ensure long-term reliability and safety in corrosive environments.

Whether you need a standard product or a custom-fabricated valve from prototype to high-volume production, our expertise ensures you get a component that meets your exact specifications.

Contact KINTEK today to discuss how our PTFE valves can solve your toughest fluid control challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- PTFE Chemical Solvent Sampling Spoon

People Also Ask

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection