The defining advantages of PTFE are its exceptional resistance to chemicals and extreme temperatures, making it one of the most reliable sealing materials for harsh industrial environments. Its non-stick surface and excellent electrical insulation further expand its utility, while its versatility allows for customization into various gasket and sheet forms to meet specific operational demands.

The core value of Polytetrafluoroethylene (PTFE) is not just one feature, but its unique combination of thermal stability, near-universal chemical inertness, and low-friction properties. This makes it the default choice for critical sealing applications where other materials would quickly fail.

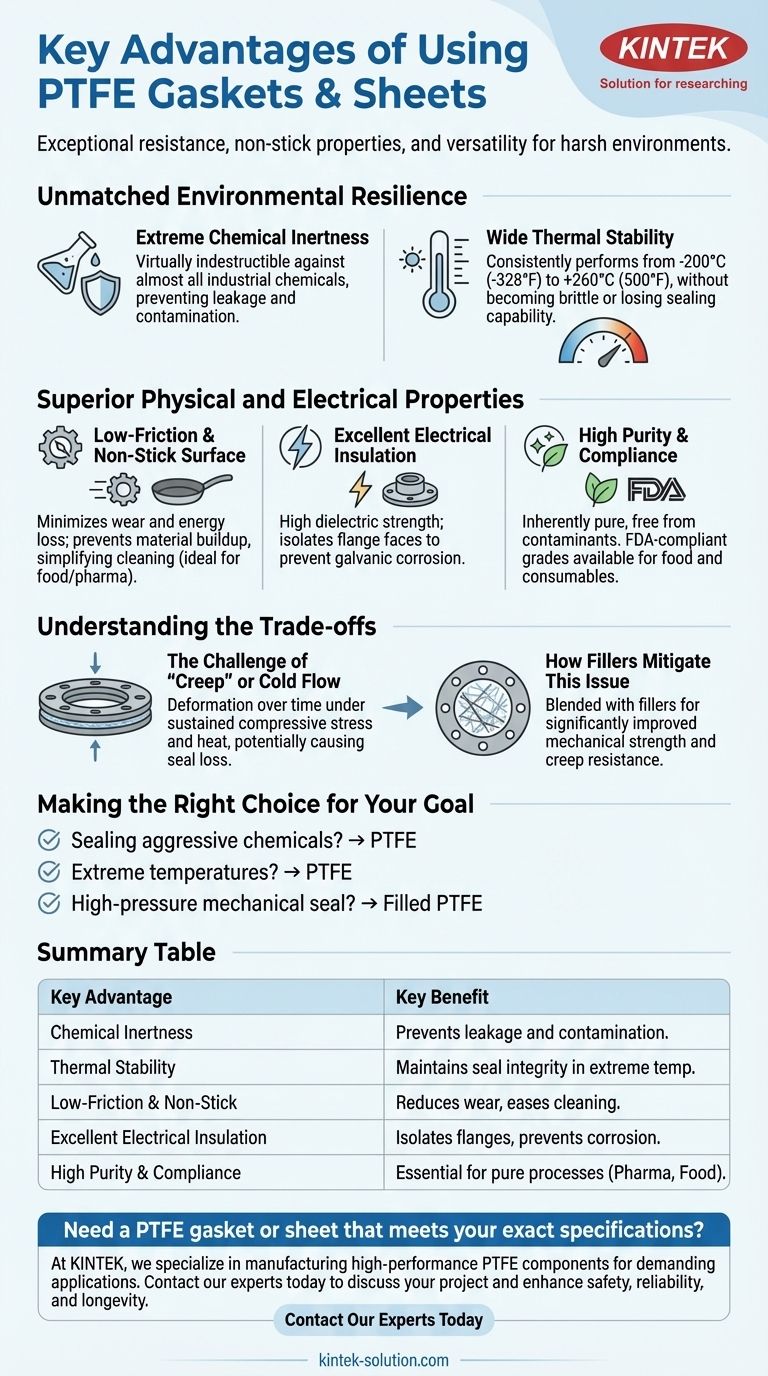

Unmatched Environmental Resilience

The primary reason engineers specify PTFE is its ability to withstand conditions that would destroy most other polymers. This resilience is rooted in its two most famous properties: chemical inertness and thermal stability.

Extreme Chemical Inertness

PTFE is virtually indestructible against almost all industrial chemicals. It reliably resists aggressive acids, bases, solvents, and corrosive agents that would degrade lesser materials.

This property ensures the integrity of the seal, preventing leakage and contamination even when handling the most challenging substances.

Wide Thermal Stability

PTFE performs consistently across an exceptionally broad temperature range, typically from cryogenic lows of -200°C (-328°F) up to high heat of +260°C (500°F).

This makes it suitable for applications involving extreme temperature fluctuations, from liquefied gas processing to high-temperature chemical reactors, without becoming brittle or losing its sealing capability.

Superior Physical and Electrical Properties

Beyond its environmental toughness, PTFE offers a set of physical characteristics that enhance its performance as a gasket and sealing material.

Low-Friction, Non-Stick Surface

PTFE has one of the lowest coefficients of friction of any solid material, creating a non-stick surface. This is critical in dynamic applications with rotating or sliding parts, as it minimizes wear and energy loss.

This "non-stick" quality also prevents material buildup on the gasket surface, simplifying cleaning and maintenance, which is vital in food processing and pharmaceutical applications.

Excellent Electrical Insulation

PTFE is a superb electrical insulator with high dielectric strength. This makes it an ideal material for gaskets that must electrically isolate flange faces to prevent galvanic corrosion or for use in electrical equipment.

High Purity and Compliance

Virgin PTFE is inherently pure and free from contaminants. This makes it an excellent choice for industries like pharmaceuticals, food and beverage, and semiconductors where process purity is non-negotiable.

Many grades of PTFE are also FDA-compliant, ensuring they are safe for contact with food and consumables.

Understanding the Trade-offs

No material is perfect, and its effectiveness depends on understanding its limitations. While PTFE's advantages are significant, its primary drawback must be considered in mechanical design.

The Challenge of "Creep" or Cold Flow

The main limitation of PTFE is its tendency to "creep" or experience "cold flow." This is the process where the material slowly deforms over time when subjected to sustained compressive stress, especially at elevated temperatures.

Impact on Sealing Performance

In a bolted flange joint, creep can cause the gasket to thin out, leading to a loss of bolt load and a reduction in sealing pressure. This can eventually compromise the integrity of the seal.

For this reason, applications involving high pressure and temperature may require periodic re-torquing of bolts or the use of specialized PTFE gaskets.

How Fillers Mitigate This Issue

To counteract creep, PTFE is often blended with filler materials like glass fiber, carbon, or graphite. These "filled PTFE" variants offer significantly improved mechanical strength and creep resistance, though they may slightly alter the material's chemical resistance or electrical properties.

Making the Right Choice for Your Goal

Selecting the right gasket material requires matching its properties to your application's primary demand.

- If your primary focus is sealing aggressive chemicals: PTFE's near-universal chemical inertness makes it the safest and most reliable choice.

- If your primary focus is performance across extreme temperatures: PTFE's wide operating temperature range ensures seal integrity in both cryogenic and high-heat conditions.

- If your primary focus is a high-pressure mechanical seal: Consider a filled PTFE to gain the necessary creep resistance while retaining its core benefits.

Choosing the correct material is the foundation for a safe, reliable, and long-lasting seal.

Summary Table:

| Key Advantage | Description | Key Benefit |

|---|---|---|

| Chemical Inertness | Resists virtually all aggressive acids, bases, and solvents. | Prevents leakage and contamination in harsh processes. |

| Thermal Stability | Performs from -200°C to +260°C (-328°F to 500°F). | Maintains seal integrity in cryogenic and high-heat applications. |

| Low-Friction & Non-Stick | One of the lowest coefficients of friction. | Reduces wear, prevents material buildup, and eases cleaning. |

| Excellent Electrical Insulation | High dielectric strength. | Ideal for isolating flanges and use in electrical equipment. |

| High Purity & Compliance | Inherently pure, with FDA-compliant grades available. | Essential for pharmaceuticals, food, beverage, and semiconductors. |

Need a PTFE gasket or sheet that meets your exact specifications?

At KINTEK, we specialize in manufacturing high-performance PTFE components—including custom gaskets, seals, liners, and labware—for the most demanding applications in the semiconductor, medical, laboratory, and industrial sectors. Whether you require a prototype or a high-volume order, our commitment to precision production ensures you get a reliable seal that delivers unmatched chemical resistance and thermal stability.

Contact our experts today to discuss your project requirements and discover how our custom PTFE solutions can enhance the safety, reliability, and longevity of your operations.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance