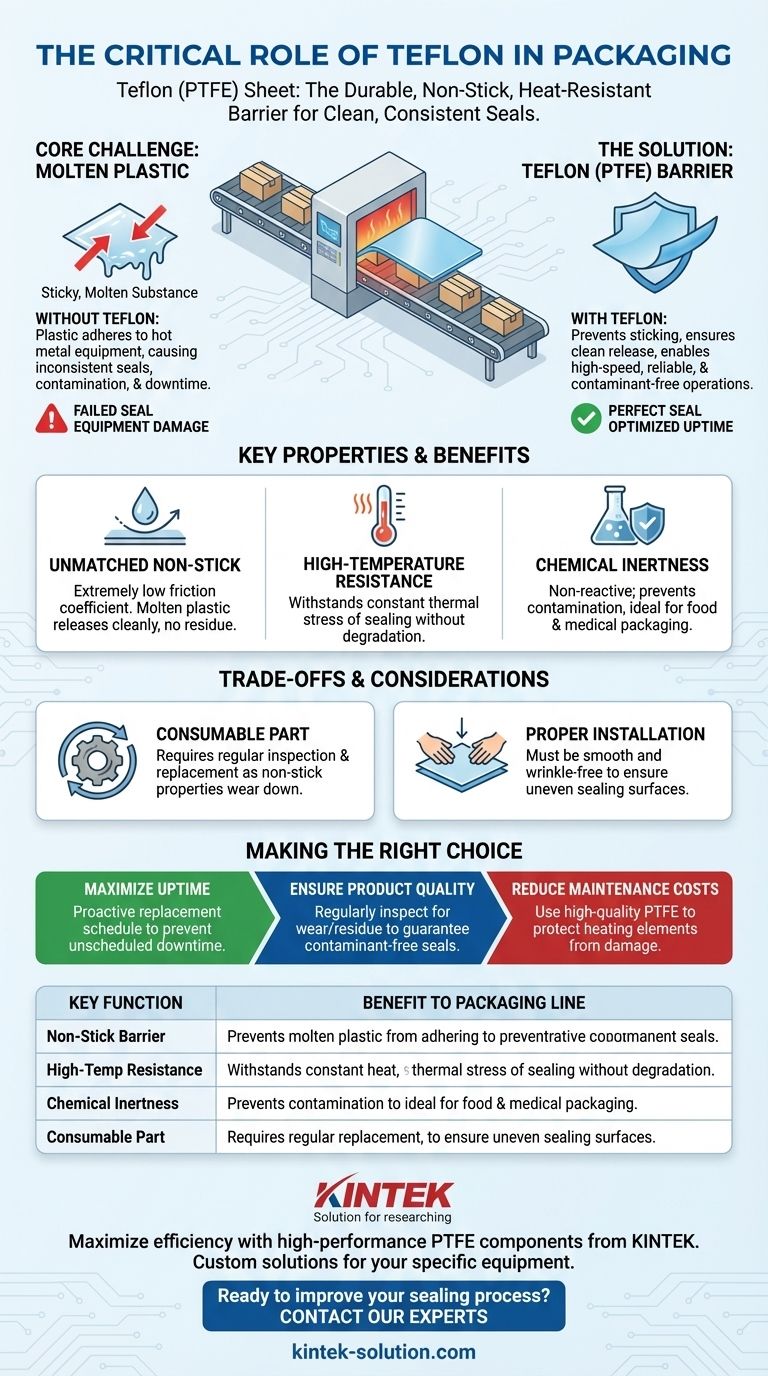

In the packaging industry, a Teflon (PTFE) sheet serves one primary, critical function: to act as a durable, non-stick, and heat-resistant barrier on heat-sealing equipment. It prevents molten packaging plastics from sticking to the hot metal surfaces of sealing jaws, wires, or bars, ensuring a clean, consistent seal every time.

The core challenge in heat-sealing plastic packaging is managing the molten material itself. Teflon sheets are the industry-standard solution because their unique properties solve this problem directly, enabling high-speed, reliable, and contaminant-free packaging operations.

The Core Problem: Sealing Thermoplastics

The Challenge of Molten Plastic

Most flexible packaging, such as bags and pouches, is made from thermoplastic films like polyethylene. To create a seal, these films must be heated to their melting point.

This process inherently creates a sticky, molten substance. Without a proper barrier, this melted plastic would immediately adhere to the hot metal sealing equipment.

The Consequence of Sticking

This build-up of plastic on sealing components leads to several critical failures. It causes inconsistent seals, product contamination, increased equipment cleaning and maintenance, and significant operational downtime.

How Teflon (PTFE) Solves the Sealing Challenge

A Teflon sheet, technically known as Polytetrafluoroethylene (PTFE), is a fluoropolymer perfectly suited to solve the challenges of heat sealing. Its value comes from a combination of three key properties.

Unmatched Non-Stick Properties

The defining characteristic of Teflon is its extremely low coefficient of friction. Its surface is so slick that virtually nothing adheres to it, including molten plastic.

This ensures that as the sealing jaws clamp down and heat the packaging film, the plastic melts, forms a seal, and releases cleanly from the equipment without leaving any residue behind.

High-Temperature Resistance

Heat sealing operates at high temperatures, often for extended periods. PTFE can withstand this constant thermal stress without degrading, melting, or losing its non-stick characteristics.

This thermal stability is essential for the reliability and longevity of the sealing process in a high-volume production environment.

Chemical Inertness

Teflon is a highly stable and non-reactive material. This is crucial in food and medical packaging applications.

It will not react with the product or the packaging film, which prevents any form of chemical contamination and helps maintain the freshness and integrity of the contents.

Understanding the Trade-offs and Considerations

Teflon is a Consumable Part

While durable, Teflon sheets and tapes on sealing equipment are not permanent. Over time, the constant heat and mechanical pressure will cause the material to wear down or tear.

This wear reduces its non-stick effectiveness, leading to poor seal quality. Therefore, it must be treated as a consumable part that requires regular inspection and replacement.

Proper Installation is Critical

The effectiveness of a Teflon sheet is highly dependent on its installation. It must be applied smoothly, without any wrinkles or creases.

A poorly installed sheet will result in an uneven sealing surface, leading to weak spots or channels in the final seal, compromising the package's integrity.

Making the Right Choice for Your Operation

To leverage Teflon effectively, you must align its use with your primary operational goals.

- If your primary focus is maximizing uptime: Implement a proactive replacement schedule for your Teflon sheets and tapes, replacing them before they fail to prevent unscheduled downtime.

- If your primary focus is ensuring product quality: Regularly inspect the surface of the Teflon for any signs of wear, residue, or degradation to guarantee a perfect, contaminant-free seal on every package.

- If your primary focus is reducing maintenance costs: Using high-quality PTFE material will extend the life of the barrier and protect the underlying heating elements from costly damage caused by plastic build-up.

Ultimately, understanding the function of this simple material is fundamental to maintaining an efficient and reliable packaging line.

Summary Table:

| Key Function | Benefit to Packaging Line |

|---|---|

| Non-Stick Barrier | Prevents molten plastic from adhering to hot sealing jaws, ensuring clean release. |

| High-Temp Resistance | Withstands constant heat of sealing process without degrading. |

| Chemical Inertness | Prevents contamination, ideal for food and medical packaging. |

| Consumable Part | Requires regular replacement to maintain seal quality and uptime. |

Maximize the efficiency and reliability of your packaging line with high-performance PTFE components from KINTEK.

Just as detailed in this article, the right Teflon sheet is critical for preventing costly downtime and ensuring perfect seals. KINTEK specializes in manufacturing precision PTFE seals, liners, and custom components for the semiconductor, medical, laboratory, and industrial packaging industries. We offer custom fabrication from prototypes to high-volume orders, ensuring you get a durable, non-stick solution tailored to your specific equipment and operational goals.

Ready to improve your sealing process and reduce maintenance? Contact our experts today to discuss your requirements and get a quote for reliable PTFE solutions.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry