In short, a PTFE lined dual plate check valve uses two spring-loaded, half-moon-shaped plates (discs) to automatically control flow direction. Forward fluid pressure pushes the plates open, and any reverse flow pressure quickly snaps them shut against a central seal. The critical feature is its internal Polytetrafluoroethylene (PTFE) lining, which provides exceptional resistance to corrosive chemicals and prevents process contamination.

This valve combines the fast-acting, non-slam design of a dual plate check valve with the superior chemical inertness of a PTFE liner. The result is a compact, reliable solution for preventing backflow in systems handling aggressive or high-purity fluids.

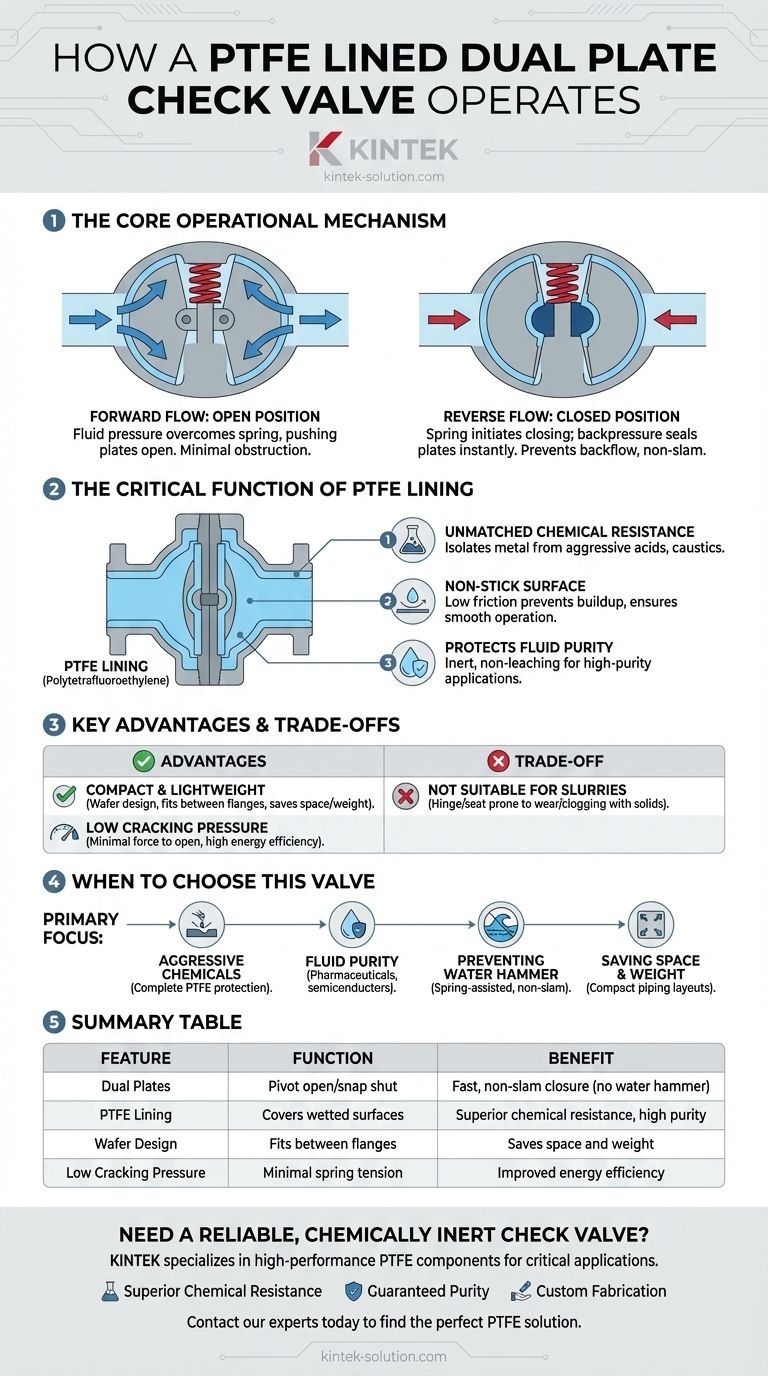

The Core Operational Mechanism

A dual plate check valve’s operation is entirely passive, relying on fluid dynamics and a simple mechanical design.

Forward Flow: The Open Position

When fluid moves in the intended direction, its pressure overcomes the light force of the internal spring. This pressure pushes the two D-shaped plates open, causing them to pivot around a central hinge pin, much like a butterfly's wings. This allows the fluid to pass through the valve with minimal obstruction.

Reverse Flow: The Closed Position

If the forward flow stops or if backpressure begins to build, the flow reversal works in concert with the spring mechanism. The spring initiates the closing action, and the backpressure then forces both plates to instantly snap shut against the valve seat, creating a tight seal and effectively preventing any backflow.

The Role of the Spring

The internal torsion spring is a critical component. Its primary function is to assist in closing the plates before significant reverse flow velocity can build up. This rapid, spring-assisted closure is what makes the valve "non-slam," as it drastically reduces the potential for damaging water hammer effects.

The Critical Function of the PTFE Lining

The PTFE liner is not just a coating; it is a thick, seamless layer that covers all wetted parts of the valve's interior. This lining is the primary reason for selecting this specific valve type.

Unmatched Chemical Resistance

PTFE is one of the most chemically inert materials used in industry. The lining isolates the valve's metal body from the process fluid, making it ideal for handling highly corrosive media such as strong acids, caustics, and other aggressive chemicals that would quickly destroy standard metal valves.

Non-Stick Surface for Reliability

PTFE has an extremely low coefficient of friction, creating a non-stick surface. This prevents process media from building up on the valve's internal components, ensuring the plates can open and close smoothly without sticking. This property significantly reduces maintenance requirements and improves long-term reliability.

Protecting Fluid Purity

Because the PTFE liner is inert and non-leaching, it does not contaminate the fluid passing through it. This makes these valves essential for high-purity applications found in the pharmaceutical, semiconductor, and food and beverage industries.

Key Advantages and Trade-offs

Understanding the design's strengths and weaknesses is crucial for proper application.

Advantage: Compact and Lightweight Design

Most dual plate check valves feature a "wafer" style body. This thin, compact design allows the valve to be installed directly between two existing pipe flanges, saving significant space and weight compared to traditional full-body check valves.

Advantage: Low Cracking Pressure

The lightweight plates and minimal spring tension mean very little forward pressure (cracking pressure) is required to open the valve. This results in low pressure drop across the valve, improving the system's overall energy efficiency.

Trade-off: Not Suitable for Slurries

The primary limitation of this design is its performance with fluids containing significant solids or abrasive slurries. The central hinge pin and seating area can become points of wear or clogging, which can prevent the valve from seating correctly and lead to failure.

When to Choose a PTFE Lined Dual Plate Check Valve

Making the right selection depends entirely on the demands of your system.

- If your primary focus is handling aggressive chemicals: This valve's complete PTFE lining provides the necessary protection against corrosion from acids, bases, and solvents.

- If your primary focus is maintaining fluid purity: This is the ideal choice for pharmaceutical or high-purity water systems where preventing process contamination is non-negotiable.

- If your primary focus is preventing water hammer: The spring-assisted, non-slam closing action makes it superior for protecting pumps and piping systems from damaging pressure surges.

- If your primary focus is saving space and weight: The wafer-style construction is perfectly suited for compact piping layouts or applications where structural load is a concern.

Ultimately, this valve is a specialized tool engineered to provide reliable backflow prevention in the most demanding chemical and high-purity environments.

Summary Table:

| Feature | Function | Benefit |

|---|---|---|

| Dual Plates | Spring-assisted plates pivot open with flow, snap shut against backflow. | Fast, non-slam closure to prevent water hammer. |

| PTFE Lining | Seamless inert liner covers all wetted interior surfaces. | Superior chemical resistance and prevents fluid contamination. |

| Wafer Design | Compact body installs directly between pipe flanges. | Saves space and weight compared to full-body valves. |

| Low Cracking Pressure | Minimal spring tension and lightweight plates. | Low pressure drop for improved system energy efficiency. |

Need a Reliable, Chemically Inert Check Valve?

For semiconductor, pharmaceutical, laboratory, and industrial applications handling aggressive or high-purity fluids, the right valve is critical. KINTEK specializes in the precision manufacturing of high-performance PTFE components, including custom-fabricated seals, liners, and labware.

We can provide the solution you need:

- Superior Chemical Resistance: Our PTFE components withstand the most corrosive environments.

- Guaranteed Purity: Prevent contamination in sensitive processes.

- Custom Fabrication: From prototypes to high-volume orders, we meet your exact specifications.

Let's discuss your specific requirements. Contact our experts today to find the perfect PTFE solution for your system.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- PTFE Chemical Solvent Sampling Spoon

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is virgin PTFE particularly suitable for food and medical applications? Ensuring Purity and Safety

- In which industries or applications are PTFE O-rings typically used? Solve Extreme Sealing Challenges

- How does a PTFE lined wafer check valve function? A Guide to Reliable Backflow Prevention

- What are the primary uses of PTFE polymer-plastic ball bearings? Ideal for Harsh & Sensitive Environments

- What are the advantages of mechanical seals with PTFE rings? Superior Chemical & Thermal Resistance

- What are the general advantages of using Teflon coating in industrial applications? Boost Efficiency & Protect Equipment

- What are the three types of springs used in PTFE seals? Optimize Your Seal Performance

- What industries benefit from using PTFE plugs? Solve Extreme Sealing Challenges