In industrial settings, Teflon coatings provide a powerful combination of surface protection and operational efficiency. These coatings, based on resins like PTFE, FEP, and PFA, deliver significant advantages by creating a non-stick, chemically inert, and temperature-resistant barrier. This protects equipment from corrosion and wear, which extends its lifespan and dramatically reduces maintenance requirements.

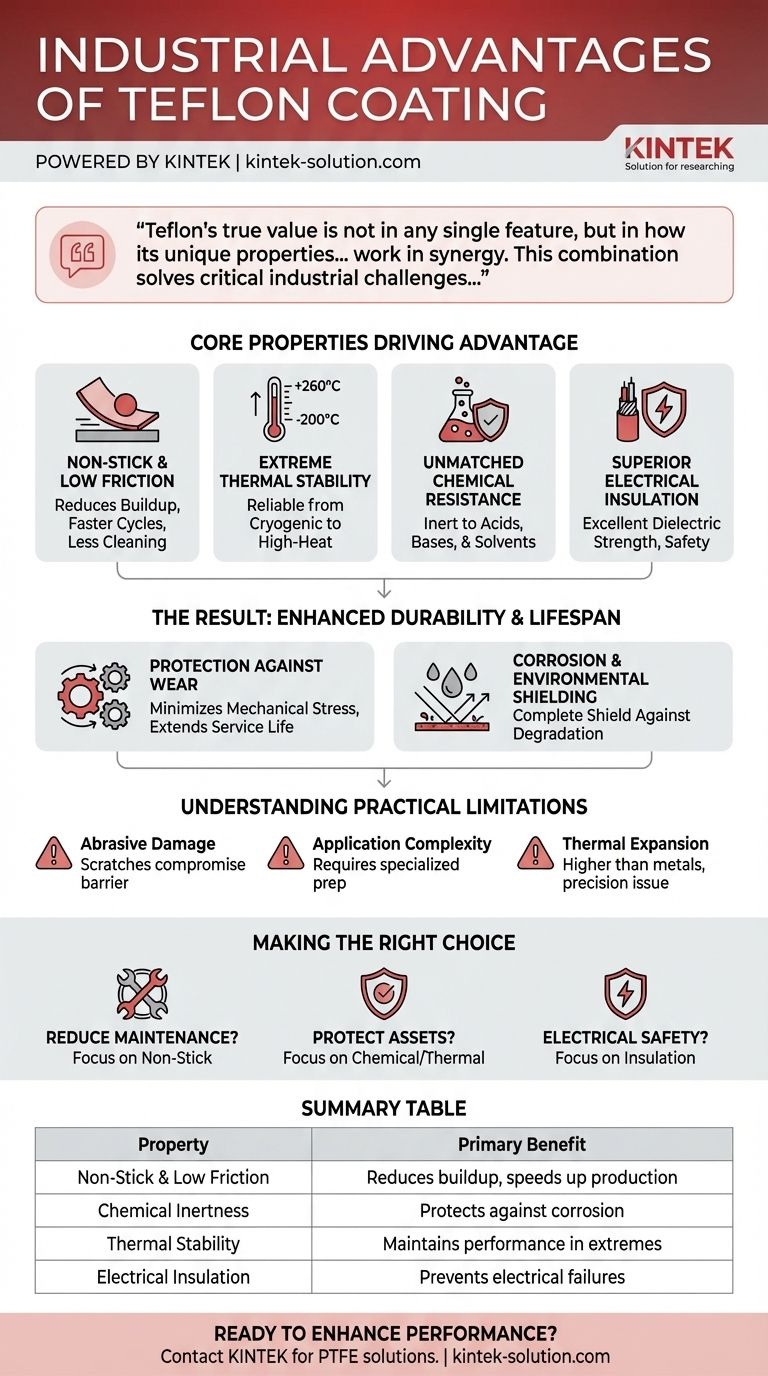

Teflon's true value is not in any single feature, but in how its unique properties—low friction, chemical inertness, and thermal stability—work in synergy. This combination solves critical industrial challenges by reducing downtime, protecting capital investments, and improving overall process reliability.

The Core Properties Driving Industrial Advantage

The benefits of Teflon stem from a few fundamental material characteristics. Understanding these properties reveals why it is so versatile across industries from food processing to construction.

Non-Stick and Low Friction

Teflon is famous for its non-stick surface. This quality prevents viscous or sticky substances from building up on machinery, which is critical in industries like food processing.

This low coefficient of friction means materials slide off easily. The result is faster production cycles, less contamination, and significantly reduced time and effort spent on cleaning.

Extreme Thermal Stability

Teflon coatings perform reliably across an exceptionally wide temperature range, typically from -200°C to +260°C (-328°F to +500°F).

This stability allows it to function without degrading in high-heat manufacturing processes or cryogenic applications, where other materials would fail.

Unmatched Chemical Resistance

Due to powerful fluorine-carbon bonds, Teflon is inert to almost all industrial chemicals, acids, and bases.

This chemical inertness makes it an ideal protective barrier for equipment in chemical manufacturing plants, preventing corrosion on pipes, valves, and vessels.

Superior Electrical Insulation

Teflon is an excellent electrical insulator with high dielectric strength. It does not conduct electricity, making it perfect for protecting sensitive components.

In construction and electronics, it is used to encase wiring and hoses, shielding them from moisture, chemicals, and temperature fluctuations that could cause electrical failures.

The Result: Enhanced Durability and Lifespan

These individual properties combine to produce the most important industrial outcome: making equipment last longer and work better.

Protection Against Wear and Tear

By reducing friction, Teflon coatings minimize mechanical stress on moving parts like bearings, gears, and bushes. This dramatically slows down wear and tear, extending the service life of critical components.

Corrosion and Environmental Shielding

The coating acts as a complete shield. It protects the underlying metal or material from moisture, chemicals, and other corrosive agents, preventing degradation and preserving the structural integrity of the asset.

Understanding the Practical Limitations

While highly effective, Teflon coatings are not a universal solution. Acknowledging their trade-offs is crucial for proper application.

Susceptibility to Abrasive Damage

Teflon's surface is relatively soft. While durable against friction, it can be scratched or damaged by sharp objects or highly abrasive materials, which can compromise its protective barrier.

Application Complexity

Achieving a durable bond requires specialized surface preparation and controlled curing processes. Improper application can lead to premature flaking or failure of the coating.

Thermal Expansion

Teflon has a higher coefficient of thermal expansion than metals. In precision engineering applications, this difference must be accounted for to maintain tight tolerances during temperature changes.

Making the Right Choice for Your Goal

Select and specify your Teflon coating based on the primary problem you need to solve.

- If your primary focus is reducing maintenance and downtime: The non-stick and low-friction properties are most critical for preventing material buildup and simplifying cleaning.

- If your primary focus is protecting assets in harsh environments: Prioritize the coating's chemical inertness and thermal stability to prevent corrosion and material degradation.

- If your primary focus is electrical safety and reliability: The coating's high dielectric strength and resistance to moisture make it an ideal choice for insulating wiring and components.

By understanding these core advantages and limitations, you can strategically leverage Teflon coatings to enhance the performance and resilience of your industrial systems.

Summary Table:

| Key Property | Primary Industrial Benefit |

|---|---|

| Non-Stick & Low Friction | Reduces material buildup, simplifies cleaning, and speeds up production cycles. |

| Chemical Inertness | Protects equipment from corrosion caused by acids, bases, and harsh chemicals. |

| Thermal Stability | Maintains performance in extreme temperatures from -200°C to +260°C. |

| Electrical Insulation | Shields wiring and components from moisture and chemicals, preventing electrical failures. |

Ready to enhance your equipment's performance and durability with precision-engineered PTFE components?

At KINTEK, we specialize in manufacturing high-quality PTFE seals, liners, and custom labware for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your components deliver the superior non-stick, chemical-resistant, and thermally stable properties you need to reduce downtime and protect your capital investment.

Contact us today to discuss your custom fabrication needs, from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials