In short, PTFE O-rings are specified for demanding applications where resistance to aggressive chemicals and extreme temperatures is critical. They are most commonly found in industries such as chemical processing, aerospace, semiconductor manufacturing, and medical devices, where standard elastomers would quickly fail.

The core reason PTFE is chosen is not for general-purpose sealing, but for its exceptional performance in extreme environments. Its chemical inertness and wide operating temperature range make it a specialized problem-solver for applications where material failure is not an option.

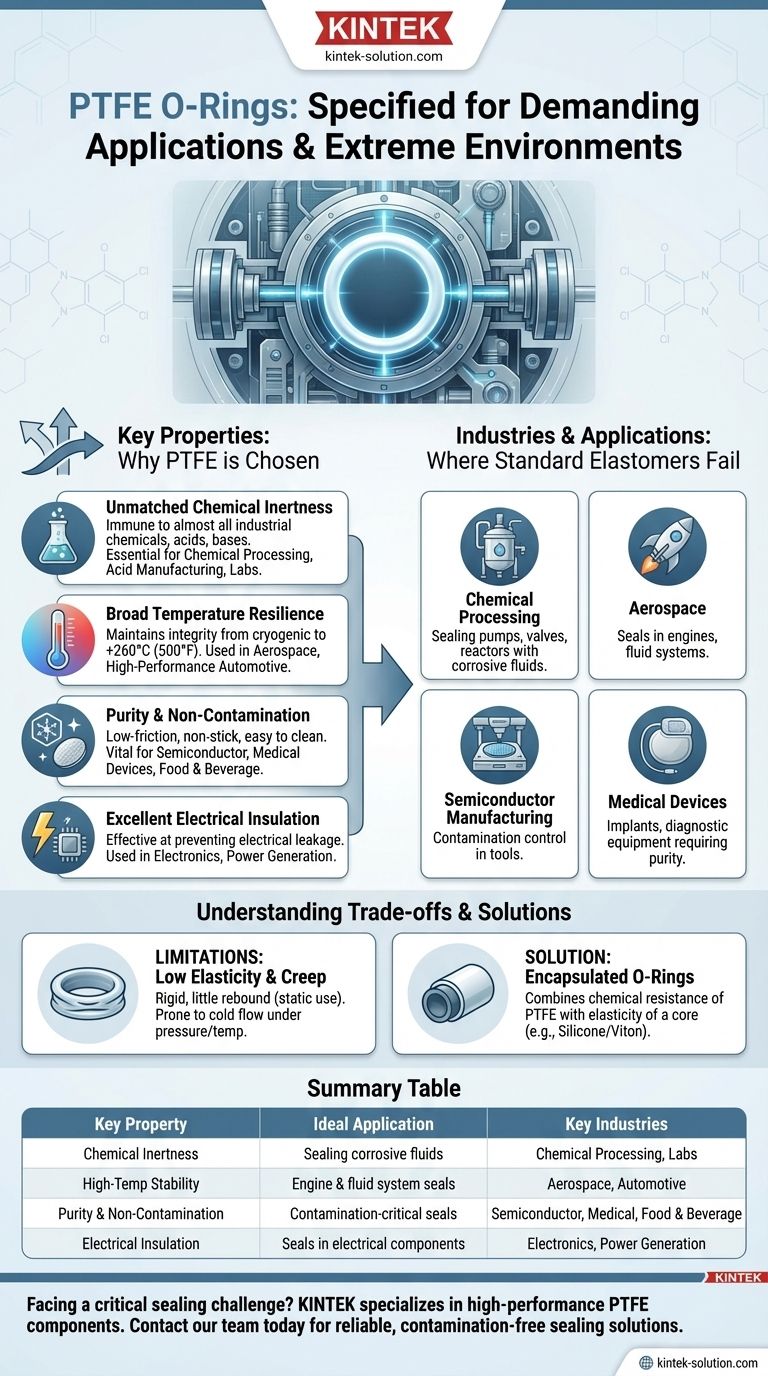

Why PTFE Is the Material of Choice in Demanding Industries

PTFE (Polytetrafluoroethylene) is not a typical O-ring material. Unlike flexible elastomers like nitrile or Viton, solid PTFE is rigid. Its value comes from a unique combination of properties that make it indispensable for certain high-stakes applications.

Unmatched Chemical Inertness

PTFE is virtually immune to almost all industrial chemicals, solvents, acids, and bases. This makes it an essential material in environments that would destroy conventional seals.

This property drives its use in chemical processing plants, acid manufacturing, and laboratory equipment for sealing pumps, valves, reactors, and flanges that handle corrosive fluids.

Broad Temperature Resilience

PTFE maintains its integrity across an exceptionally wide temperature range, from cryogenic conditions up to approximately 260°C (500°F).

This thermal stability is why it is heavily relied upon in the aerospace industry for seals and gaskets in engines and fluid systems, as well as in high-performance automotive applications like valve seats and piston rings.

Purity and Non-Contamination

PTFE has an extremely low-friction, non-stick surface that resists buildup and is easy to clean. This inherent purity is vital where contamination control is paramount.

This makes it a primary choice for semiconductor manufacturing tools, medical devices and implants, and the food and beverage industry, where preventing product contamination is a critical requirement.

Excellent Electrical Insulation

PTFE is one of the best known electrical insulators, making it highly effective at preventing electrical leakage.

This property is leveraged in electronics and power generation, where PTFE is used for wire insulation, gaskets in transformers, and seals in other electrical components.

Understanding the Trade-offs

While powerful, PTFE is a specialized material with clear limitations. Understanding these trade-offs is crucial for correct application.

Low Elasticity and Compression Set

Solid PTFE O-rings are rigid and have very little elasticity. They do not compress and rebound like rubber O-rings, which can make achieving a perfect seal more difficult.

This lack of "memory" means they are best suited for static applications, like flange gaskets, rather than dynamic ones with significant movement.

The Solution: Encapsulated O-Rings

To overcome the rigidity issue, PTFE-encapsulated O-rings are often used. These combine a flexible inner core (like silicone or Viton) with a seamless outer PTFE jacket.

This design provides the chemical resistance of PTFE with the elasticity of a standard elastomer, offering the best of both worlds for a wider range of sealing applications.

Susceptibility to Creep

Under sustained pressure and temperature, PTFE can be prone to "creep," or cold flow, where the material slowly deforms over time. This must be accounted for in the design of the sealing gland to ensure long-term performance.

Making the Right Choice for Your Goal

Selecting the right material depends entirely on the demands of your specific operating environment.

- If your primary focus is surviving aggressive chemicals: PTFE is the default choice, as few other materials can offer its level of near-universal chemical resistance.

- If your primary focus is high-temperature stability: PTFE provides reliable performance in applications where most elastomers would degrade or fail.

- If you need both chemical resistance and elastic sealing: A PTFE-encapsulated O-ring is likely the ideal solution, providing flexibility that solid PTFE cannot.

Ultimately, choosing PTFE is a decision to prioritize chemical and thermal resilience above all other sealing characteristics.

Summary Table:

| Key Property | Ideal Application | Key Industries |

|---|---|---|

| Chemical Inertness | Sealing corrosive fluids | Chemical Processing, Labs |

| High-Temp Stability | Engine & fluid system seals | Aerospace, Automotive |

| Purity & Non-Contamination | Contamination-critical seals | Semiconductor, Medical, Food & Beverage |

| Electrical Insulation | Seals in electrical components | Electronics, Power Generation |

Facing a critical sealing challenge with aggressive chemicals or extreme temperatures? KINTEK specializes in manufacturing high-performance PTFE components, including custom O-rings, seals, liners, and labware. We serve semiconductor, medical, laboratory, and industrial industries by prioritizing precision and offering custom fabrication from prototypes to high-volume orders. Let our expertise in PTFE provide the reliable, contamination-free sealing solution you need. Contact our team today to discuss your specific requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications