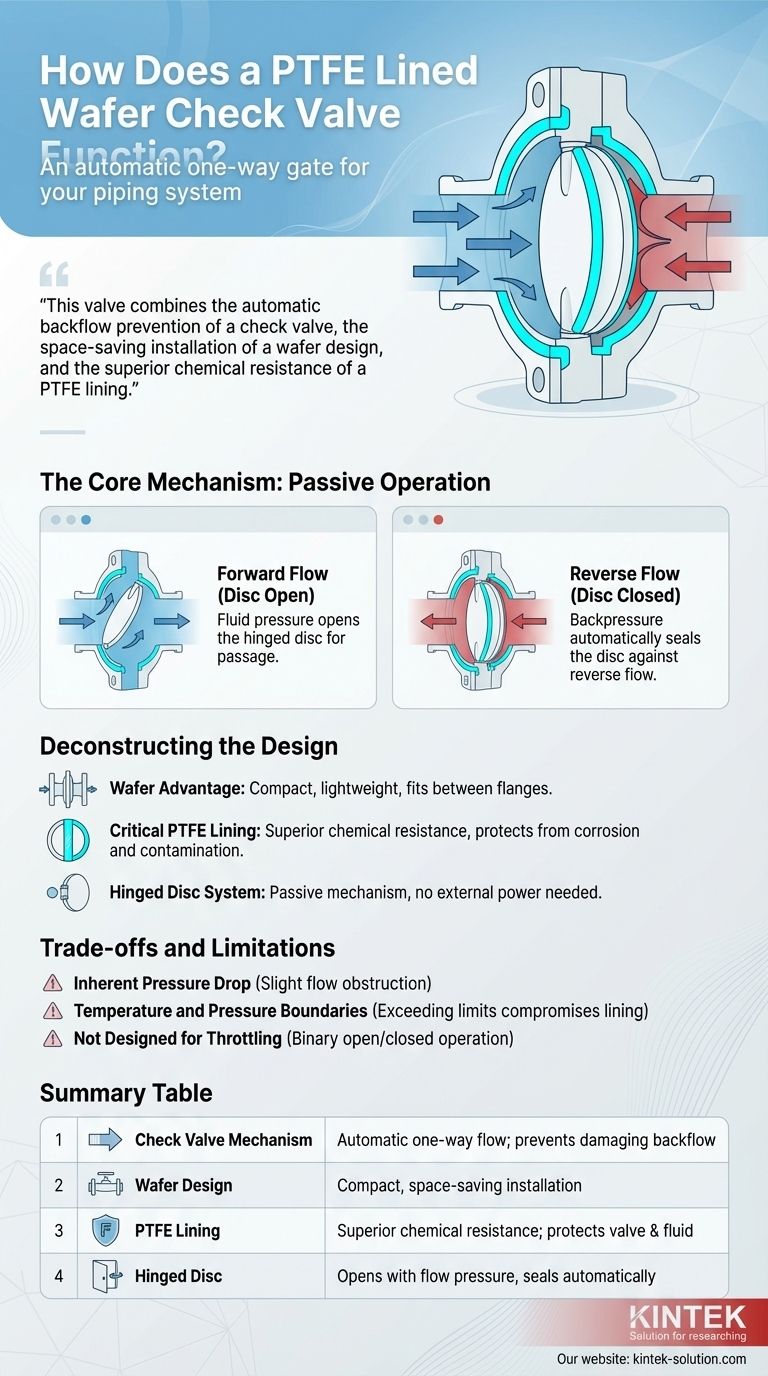

At its core, a PTFE lined wafer check valve is an automatic one-way gate for your piping system. It uses a simple, hinged disc that is pushed open by fluid moving in the desired direction. If the flow stops or attempts to reverse, the disc immediately swings shut against its seat, creating a seal that prevents any backflow.

This valve combines the automatic backflow prevention of a check valve, the space-saving installation of a wafer design, and the superior chemical resistance of a PTFE lining. Its primary purpose is to protect equipment and processes from the damaging effects of reverse flow in highly corrosive environments.

The Core Mechanism: How It Prevents Backflow

The valve's operation is entirely passive, relying on the pressure and direction of the fluid itself. It requires no external power or manual intervention.

The Hinged Disc System

A disc is mounted inside the valve body on a hinge. When fluid flows in the intended direction, the pressure exerted by the moving fluid pushes this disc open, allowing for passage.

The disc is designed to remain open as long as there is sufficient forward flow pressure to overcome its weight and the force of gravity.

The Automatic Closing Action

When the forward flow ceases, the disc begins to close. If any backpressure or reverse flow occurs, it pushes the disc firmly against its seat, creating a tight seal.

This automatic action is critical for protecting upstream equipment, such as pumps, from damage that can be caused by backflow and associated water hammer effects.

Deconstructing the Design: Key Features Explained

The name "PTFE lined wafer check valve" describes three distinct features, each serving a critical purpose in its application.

The "Wafer" Advantage

The term wafer refers to the valve's body style. It is a thin, compact design without its own flanges, intended to be sandwiched directly between two existing pipe flanges.

This design makes the valve significantly lighter, more compact, and often less expensive to install than traditional full-bodied flanged valves, making it ideal for systems where space is a constraint.

The Critical "PTFE Lining"

PTFE (Polytetrafluoroethylene), commonly known as Teflon, is a high-performance polymer renowned for its extreme chemical inertness and low-friction properties.

In this valve, a thick layer of PTFE lines all surfaces that come into contact with the fluid. This lining acts as a protective barrier, completely isolating the metal valve body from the process media. This prevents corrosion of the valve and contamination of the fluid, extending the valve's service life in aggressive applications.

Understanding the Trade-offs and Limitations

While highly effective, this valve type has specific characteristics that make it suitable for some applications but not others.

Inherent Pressure Drop

Like all check valves, the internal disc mechanism creates a slight obstruction in the flow path. This results in a small but measurable pressure drop across the valve, which must be accounted for in system design.

Temperature and Pressure Boundaries

PTFE has specific temperature and pressure limitations. Exceeding these manufacturer-rated limits can compromise the integrity of the lining, leading to valve failure. It's crucial to ensure the valve's specifications match the system's operating conditions.

Not Designed for Throttling

A check valve is a binary device; it is designed to be either fully open or fully closed. It cannot be used to regulate or "throttle" the rate of flow through a pipe.

Making the Right Choice for Your Goal

Selecting this valve depends on balancing the needs for backflow prevention, chemical compatibility, and physical installation constraints.

- If your primary focus is handling corrosive chemicals: The PTFE lining is the most important feature, ensuring the valve's longevity and protecting media purity.

- If your primary focus is protecting sensitive equipment: The automatic check function is critical for preventing damaging backflow that could harm pumps or disrupt processes.

- If your primary focus is efficient installation in tight spaces: The compact and lightweight wafer design provides a clear advantage over larger, heavier valve types.

Ultimately, this specialized valve provides a highly reliable, chemically-resistant safeguard for critical piping systems.

Summary Table:

| Feature | Function & Benefit |

|---|---|

| Check Valve Mechanism | Automatic one-way flow; prevents damaging backflow to protect pumps and equipment. |

| Wafer Design | Compact, lightweight body installed between flanges; saves space and reduces cost. |

| PTFE Lining | Provides superior chemical resistance; protects valve from corrosion and fluid from contamination. |

| Hinged Disc | Opens with forward flow pressure, swings shut automatically to seal against reverse flow. |

Need a reliable, corrosion-resistant check valve for your critical process?

At KINTEK, we specialize in the precision manufacturing of high-performance PTFE components, including custom wafer check valves, seals, liners, and labware. Whether you need a prototype for testing or high-volume production for the semiconductor, medical, laboratory, or industrial sectors, our expertise ensures your valves meet the highest standards for durability and chemical compatibility.

Contact KINTEK today to discuss your specific requirements and let our solutions protect your system.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- PTFE Chemical Solvent Sampling Spoon

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments