In short, PTFE (Polytetrafluoroethylene) polymer-plastic ball bearings are primarily used in applications where chemical resistance, self-lubrication, and sterility are critical. They are the go-to solution for harsh or sensitive environments, including chemical processing equipment, medical implants, semiconductor manufacturing, and food and beverage machinery.

The decision to use a PTFE bearing is not about seeking superior mechanical strength; it is about solving environmental challenges that would cause traditional lubricated steel bearings to corrode, seize, or contaminate their surroundings.

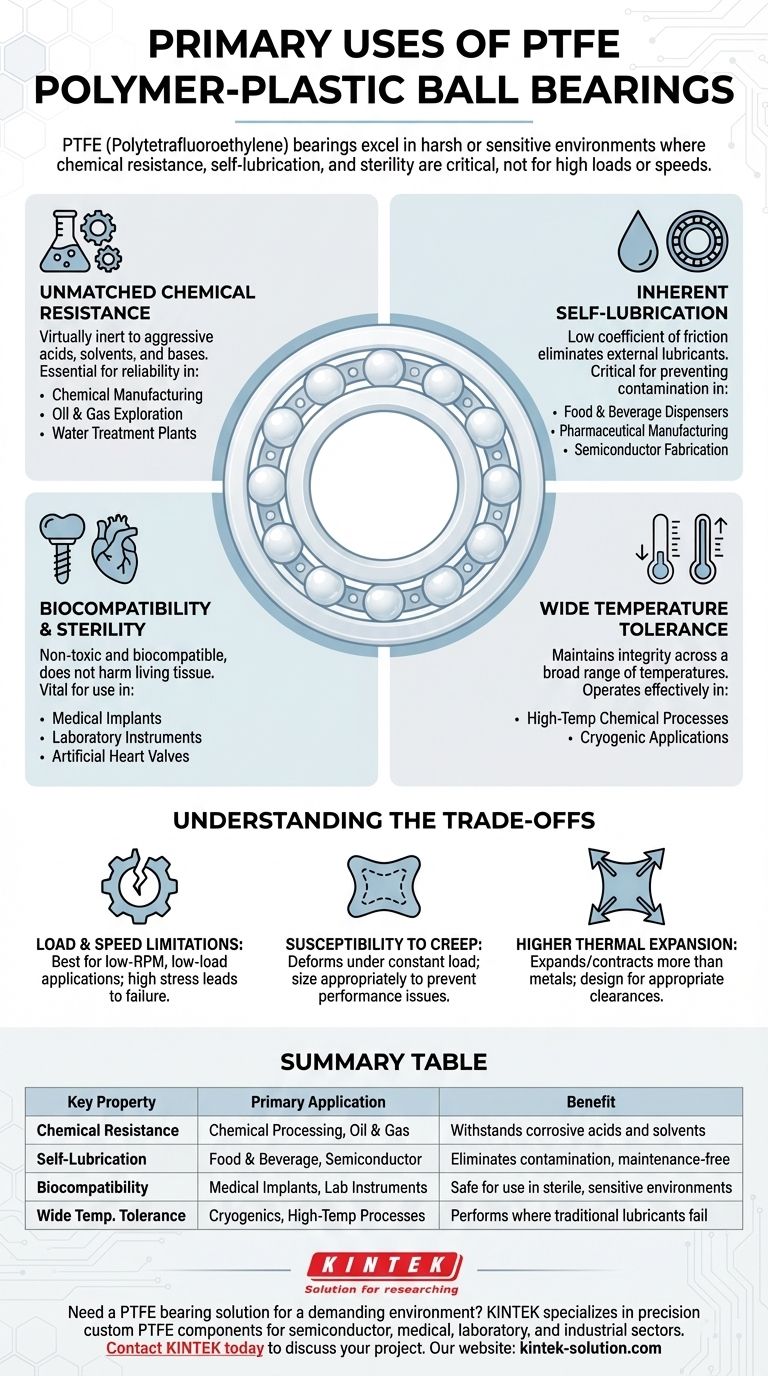

The Core Properties Driving PTFE Adoption

To understand where PTFE bearings excel, you must first understand the material's unique characteristics. Its value is rooted in its inherent chemical and physical properties, not in its ability to handle extreme loads or speeds.

Unmatched Chemical Resistance

PTFE is virtually inert, meaning it does not react with most chemicals. This makes it an essential material in highly corrosive environments.

It can withstand aggressive acids, solvents, and bases without degrading, ensuring operational reliability in applications like chemical manufacturing, oil and gas exploration, and water treatment plants.

Inherent Self-Lubrication

One of the most significant advantages of PTFE is its extremely low coefficient of friction. The material is inherently slick, which eliminates the need for external lubricants like grease or oil.

This self-lubricating property is critical in environments where contamination is unacceptable, such as food and beverage dispensers, pharmaceutical manufacturing, and semiconductor fabrication. It also means the bearings are effectively maintenance-free.

Biocompatibility and Sterility

PTFE is non-toxic and biocompatible, meaning it does not harm living tissue. This property, combined with its resistance to bodily fluids, makes it a vital material in the medical field.

You will find it used in sensitive laboratory instruments and even in critical medical implants, such as components for artificial heart valves.

Wide Temperature Tolerance

While not intended for extreme structural loads, PTFE maintains its integrity across a broad range of temperatures.

It can operate effectively in high-temperature chemical processes and cryogenic applications where traditional lubricants would either burn off or freeze solid.

Understanding the Trade-offs

While PTFE offers unique solutions, it is not a universal replacement for steel bearings. Its advantages in harsh environments come with mechanical limitations that are critical to understand.

Load and Speed Limitations

The primary trade-off is mechanical strength. PTFE and other plastic bearings cannot handle the high loads or rotational speeds that hardened steel bearings can.

They are best suited for low-RPM, low-load applications where environmental resilience is the most important factor. Applying them in high-stress machinery will lead to rapid failure.

Susceptibility to Creep

Like most polymers, PTFE is susceptible to "creep," which is the tendency to slowly deform over time when under a constant load.

This must be factored into the design of the application. The bearing must be appropriately sized for the sustained load to prevent dimensional changes that could compromise performance.

Higher Thermal Expansion

PTFE has a higher coefficient of thermal expansion than metals. This means it expands and contracts more significantly with temperature changes.

Engineers must account for this by designing in appropriate clearances to prevent the bearing from seizing within its housing during thermal cycles.

Making the Right Choice for Your Application

Selecting the correct bearing material depends entirely on the primary demands of your specific use case.

- If your primary focus is corrosion or chemical resistance: PTFE bearings are an excellent choice, providing longevity where metals would quickly fail.

- If your primary focus is high-speed or high-load performance: A traditional steel bearing is almost certainly the correct engineering choice.

- If your primary focus is eliminating contamination and maintenance: PTFE's self-lubricating nature makes it a superior option for sterile or cleanroom environments.

Ultimately, PTFE bearings are specialized components designed to thrive in conditions that are simply too hostile for conventional bearing solutions.

Summary Table:

| Key Property | Primary Application | Benefit |

|---|---|---|

| Chemical Resistance | Chemical Processing, Oil & Gas | Withstands corrosive acids and solvents |

| Self-Lubrication | Food & Beverage, Semiconductor | Eliminates contamination, maintenance-free |

| Biocompatibility | Medical Implants, Lab Instruments | Safe for use in sterile, sensitive environments |

| Wide Temp. Tolerance | Cryogenics, High-Temp Processes | Performs where traditional lubricants fail |

Need a PTFE bearing solution for a demanding environment?

KINTEK specializes in the precision manufacturing of custom PTFE components, including seals, liners, labware, and bearings. We serve the semiconductor, medical, laboratory, and industrial sectors, providing solutions that offer superior chemical resistance, self-lubrication, and sterility.

Whether you need a prototype or a high-volume order, our expertise ensures a component that meets your exact specifications for performance in harsh or sensitive conditions.

Contact KINTEK today to discuss your project requirements and discover how our PTFE expertise can benefit your application.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability