To put it directly, PTFE sealed ball bearings are among the most durable options available for many applications. Their exceptional longevity is not due to the bearing's metal alone, but rather the unique and robust properties of the Polytetrafluoroethylene (PTFE) material used to create the seal, which provides a superior defense against the primary causes of bearing failure.

The core reason for their durability lies in the PTFE seal's ability to create a near-perfect, low-friction barrier. This protects the internal components from contamination while demanding virtually no maintenance, resulting in a significantly longer and more reliable service life.

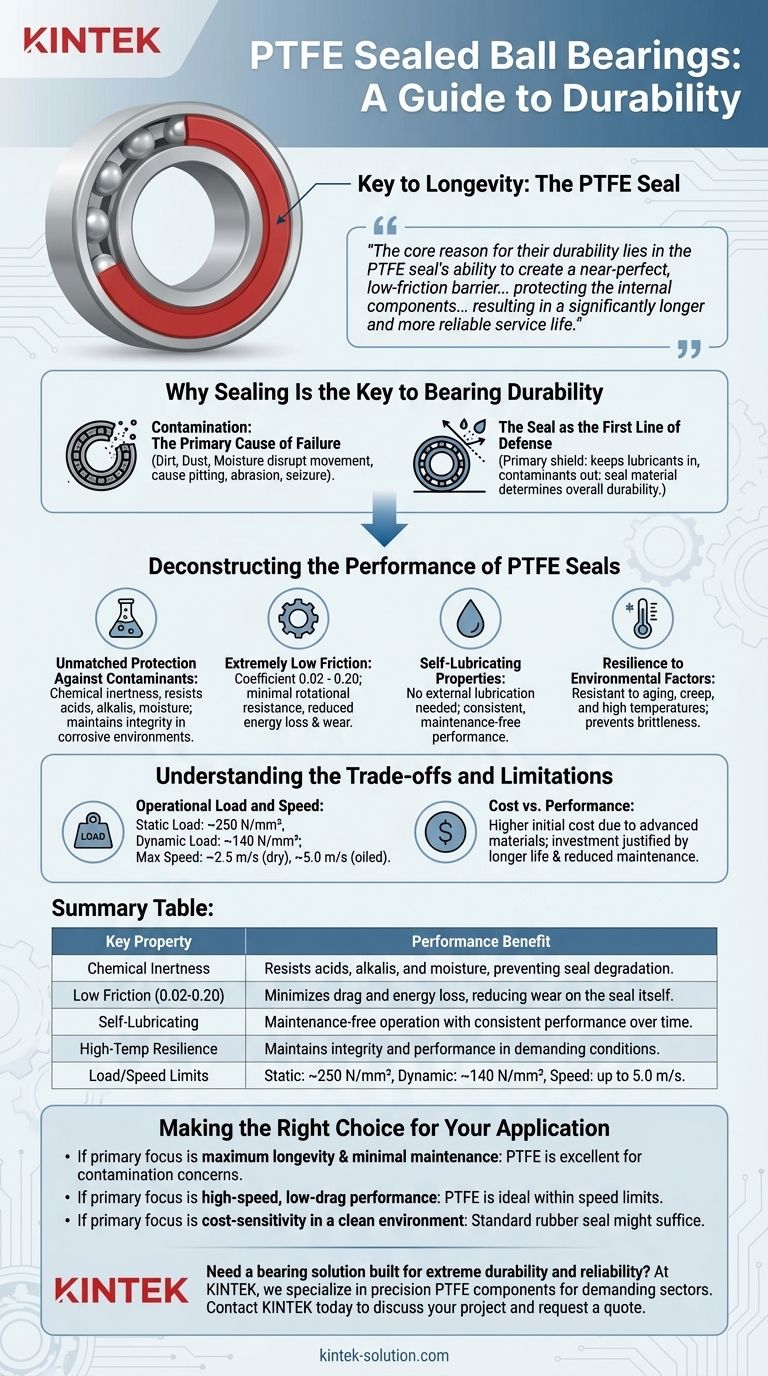

Why Sealing Is the Key to Bearing Durability

Before analyzing the specifics of PTFE, it is critical to understand that the lifespan of a ball bearing is most often determined by its seal, not its steel.

Contamination: The Primary Cause of Failure

The vast majority of premature bearing failures are caused by contamination. When microscopic particles of dirt, dust, or moisture penetrate a bearing, they disrupt the smooth movement of the balls, causing pitting, abrasion, and eventual seizure.

The Seal as the First Line of Defense

A bearing's seal is its primary shield. Its job is to keep lubricants in and contaminants out. The material properties of the seal—its resistance to wear, chemicals, and aging—are therefore the most critical factors in determining the bearing's overall durability.

Deconstructing the Performance of PTFE Seals

PTFE, commonly known by the brand name Teflon, possesses a unique combination of characteristics that make it an exceptional sealing material for high-performance bearings.

Unmatched Protection Against Contaminants

The chemical inertness of PTFE gives it excellent resistance to acids, alkalis, and moisture. This ensures the seal does not degrade even in corrosive environments, maintaining its integrity and protecting the bearing's internal raceways and balls.

Extremely Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, with a typical value between 0.02 and 0.20. This means the seal itself generates minimal rotational resistance or drag, reducing energy loss and preventing the seal from wearing itself out over time.

Self-Lubricating Properties

A key advantage of PTFE is its self-lubricating nature. The material does not require external lubrication to maintain its low-friction surface. This quality contributes to a "maintenance-free" design, as the seal's performance remains consistent throughout the bearing's life.

Resilience to Environmental Factors

The molecular structure of PTFE makes it highly resistant to aging and creep under load. It also has a high-temperature tolerance, ensuring the seal remains effective and does not become brittle or deformed in demanding operational conditions.

Understanding the Trade-offs and Limitations

While highly durable, PTFE sealed bearings are engineered for specific operational windows. Understanding their limits is key to leveraging their strengths.

Operational Load and Speed

PTFE sealed bearings have defined mechanical limits. Based on typical specifications, they can handle static loads up to 250 N/mm² and dynamic loads of 140 N/mm². Maximum sliding speeds are around 2.5 m/s when dry and can be as high as 5.0 m/s in an oiled environment. Exceeding these thresholds can lead to premature wear.

Cost vs. Performance

The advanced material science and manufacturing involved in high-quality PTFE seals often result in a higher initial cost compared to bearings with conventional rubber or metal shields. The investment is justified by longer life and reduced maintenance needs, but the upfront cost is a necessary consideration.

Making the Right Choice for Your Application

Selecting the correct bearing requires aligning its properties with your primary goal.

- If your primary focus is maximum longevity and minimal maintenance: PTFE sealed bearings are an excellent choice, especially in environments where dirt, moisture, or chemicals are a concern.

- If your primary focus is high-speed, low-drag performance: The exceptionally low friction of PTFE seals makes them ideal for applications where every bit of efficiency counts, provided you operate within their specified speed limits.

- If your primary focus is cost-sensitivity in a clean environment: A standard rubber-sealed bearing may be sufficient if the risk of contamination is low and periodic maintenance is acceptable.

Ultimately, choosing a PTFE sealed bearing is an investment in long-term reliability and consistent performance.

Summary Table:

| Key Property | Performance Benefit |

|---|---|

| Chemical Inertness | Resists acids, alkalis, and moisture, preventing seal degradation. |

| Low Friction (0.02-0.20) | Minimizes drag and energy loss, reducing wear on the seal itself. |

| Self-Lubricating | Maintenance-free operation with consistent performance over time. |

| High-Temp Resilience | Maintains integrity and performance in demanding conditions. |

| Load/Speed Limits | Static: ~250 N/mm², Dynamic: ~140 N/mm², Speed: up to 5.0 m/s. |

Need a bearing solution built for extreme durability and reliability?

At KINTEK, we specialize in precision PTFE components, including custom seals and liners for demanding applications in the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your equipment benefits from the superior protection and long service life of high-performance PTFE.

Let us provide a solution tailored to your specific operational needs, from prototype to high-volume production.

Contact KINTEK today to discuss your project and request a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the key features of Teflon bushings? Unlock Maintenance-Free Performance

- What are the advantages of PTFE/PFA lining in steel pipes? Achieve Superior Corrosion Resistance and Purity

- How does PTFE compare to other fluoropolymers in chemical resistance? Discover the Benchmark for Chemical Inertness

- Why are PTFE gaskets preferred in high-temperature environments? Ensure Reliable Sealing Under Extreme Heat

- What are some alternatives to Teflon for machining? Optimize Your Material Selection for Specialized Applications

- When should RPTFE not be used? Avoid Component Failure with HF and Caustics

- How do Medical Grade PTFE Liners exhibit chemical resistance? Unmatched Inertness for Medical Devices

- What are the advantages of machining Teflon? Unlock Superior Performance for Critical Components