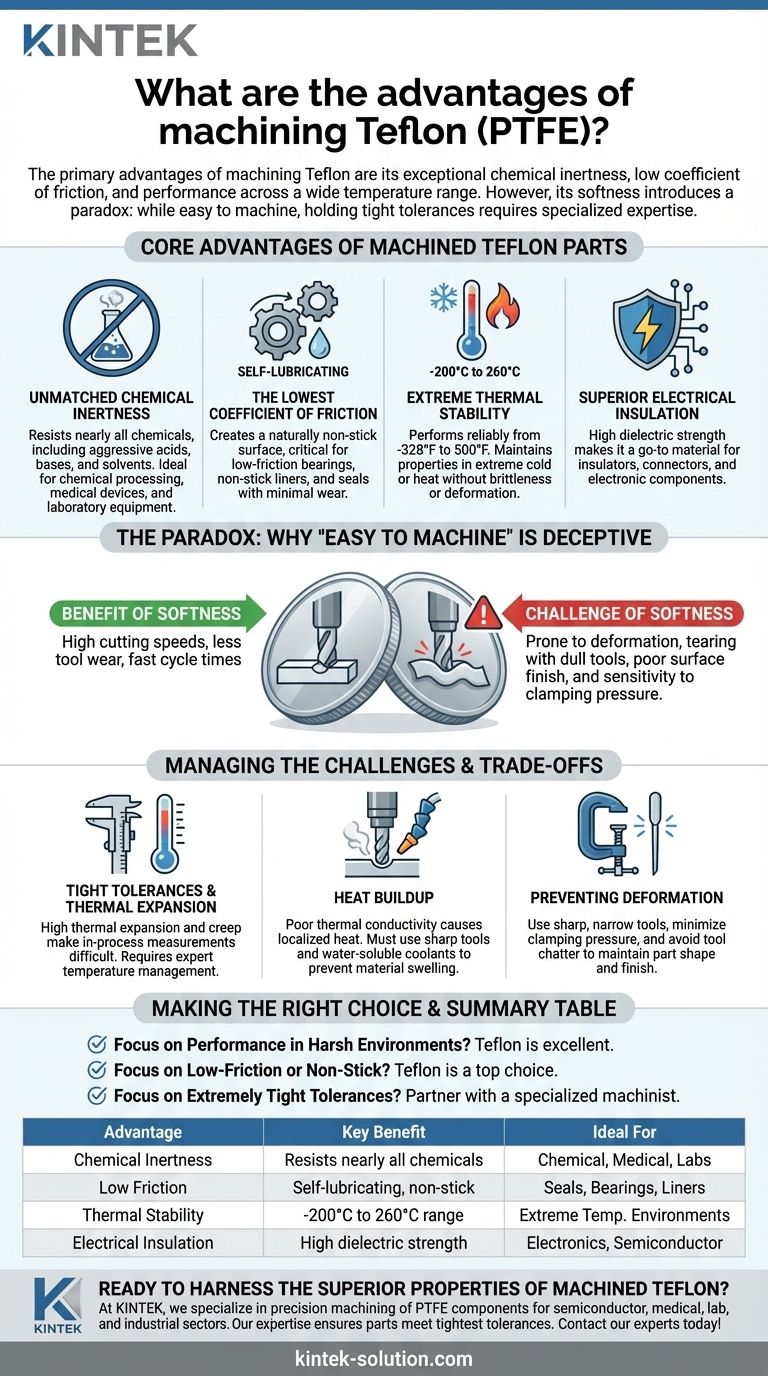

The primary advantages of machining Teflon (PTFE) are its exceptional chemical inertness, an extremely low coefficient of friction, and excellent performance across a wide temperature range. These inherent material properties are retained in the final machined part, making it a superior choice for demanding applications where other materials would fail.

While Teflon's softness makes it seem easy to machine, its true value is unlocked by understanding a critical paradox: the very properties that make the material desirable also introduce specific challenges, such as managing thermal expansion and creep to hold tight tolerances.

The Core Advantages of Machined Teflon Parts

Machining allows the unique properties of raw Teflon stock to be shaped into precise components like seals, bearings, insulators, and valves. The final part's performance is a direct result of these core material advantages.

Unmatched Chemical Inertness

Teflon is renowned for its resistance to nearly all chemicals, including aggressive acids, bases, and solvents. This makes it an ideal material for components used in chemical processing, medical devices, and laboratory equipment where corrosion or material degradation is not an option.

The Lowest Coefficient of Friction

Among all solid materials, Teflon possesses one of the lowest coefficients of friction. This creates a naturally non-stick and self-lubricating surface, which is critical for applications like low-friction bearings, non-stick liners, and high-performance seals that must operate smoothly with minimal wear.

Extreme Thermal Stability

Machined Teflon parts perform reliably across an exceptionally broad temperature range, typically from -200°C to 260°C (-328°F to 500°F). Unlike many plastics that become brittle in the cold or deform under heat, Teflon maintains its key properties in extreme conditions.

Superior Electrical Insulation

Teflon is an excellent electrical insulator with high dielectric strength. This makes it a go-to material for manufacturing insulators, connectors, and other components for the electronics and semiconductor industries.

Durability and Purity

Teflon is also resistant to UV radiation and weathering, does not absorb water, and is often compliant with food-grade standards. This makes it a durable, long-lasting, and safe choice for a wide array of applications.

The Paradox: Why "Easy to Machine" is Deceptive

Teflon is often described as "easy to machine" because its softness and density require less force and cause less tool wear than metals. However, this simplicity is misleading and overlooks the skill required to produce an accurate part.

The Benefit of Softness

The material's low resistance allows for high cutting speeds and feeds, which can reduce cycle times. Sharp tools cut through it cleanly with minimal wear, a distinct advantage over machining abrasive composites or hardened steels.

The Challenge of Softness

The same softness makes Teflon prone to deformation. If tools are not extremely sharp, they can push or tear the material rather than shear it cleanly, resulting in a poor surface finish. Likewise, excessive clamping pressure can easily crush or distort the workpiece.

Understanding the Trade-offs and Machining Challenges

Successfully machining Teflon means directly addressing its unique behaviors. The primary challenge is not cutting the material, but controlling its response to the forces and heat of the machining process.

The Difficulty with Tight Tolerances

Achieving tight dimensional tolerances is the single greatest challenge. This is due to two factors: a high coefficient of thermal expansion and stress creep. Even a small amount of heat from cutting will cause the material to expand significantly, making in-process measurements unreliable.

Managing Heat Buildup

Teflon is a poor thermal conductor, meaning heat generated at the cutting edge does not dissipate quickly. This localized heat can cause material to swell or even clog tooling. Using water-soluble coolants and ensuring tools are sharp are critical for managing this effect.

Preventing Part Deformation

Controlling part shape requires a specialized approach. This includes using sharp, narrow tools to minimize cutting forces, applying just enough clamping pressure to secure the part without distortion, and avoiding tool chatter that can mar the surface.

Making the Right Choice for Your Application

Choosing to machine Teflon is a decision based on the final part's required performance. Understanding the balance between its benefits and its machining demands is key to a successful outcome.

- If your primary focus is performance in harsh environments: Teflon is an excellent choice due to its unparalleled chemical and thermal resistance.

- If your primary focus is low-friction or non-stick surfaces: Teflon is one of the best materials available for applications like high-performance seals, bearings, or liners.

- If your primary focus is holding extremely tight tolerances: You must partner with a machinist who specializes in plastics and understands how to manage Teflon's unique thermal expansion and creep properties.

Ultimately, the advantages of a machined Teflon component are immense, provided the manufacturing process is expertly tailored to the material's distinct personality.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Chemical Inertness | Resists nearly all chemicals | Chemical processing, medical devices, labs |

| Low Friction | Self-lubricating, non-stick | Seals, bearings, liners |

| Thermal Stability | Performs from -200°C to 260°C | Extreme temperature environments |

| Electrical Insulation | High dielectric strength | Electronics, semiconductor components |

Ready to harness the superior properties of machined Teflon for your project?

At KINTEK, we specialize in precision machining of PTFE components like seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in managing Teflon's unique challenges ensures your parts meet the tightest tolerances and perform reliably in the most demanding conditions.

From custom prototypes to high-volume production, we deliver the quality and precision your application requires.

Contact our experts today to discuss your Teflon machining needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining