The fundamental advantage of lining steel pipes with PTFE/PFA is the creation of a composite material that pairs the immense structural strength of steel with the near-universal chemical inertness of a fluoropolymer liner. This combination results in a piping system that can safely transport highly corrosive or pure substances under pressure, offering exceptional durability, longevity, and process reliability.

This system solves a critical engineering challenge: how to handle aggressive fluids without sacrificing the mechanical integrity required for industrial applications. It effectively separates the structural load-bearing function (steel) from the chemical containment function (PTFE/PFA).

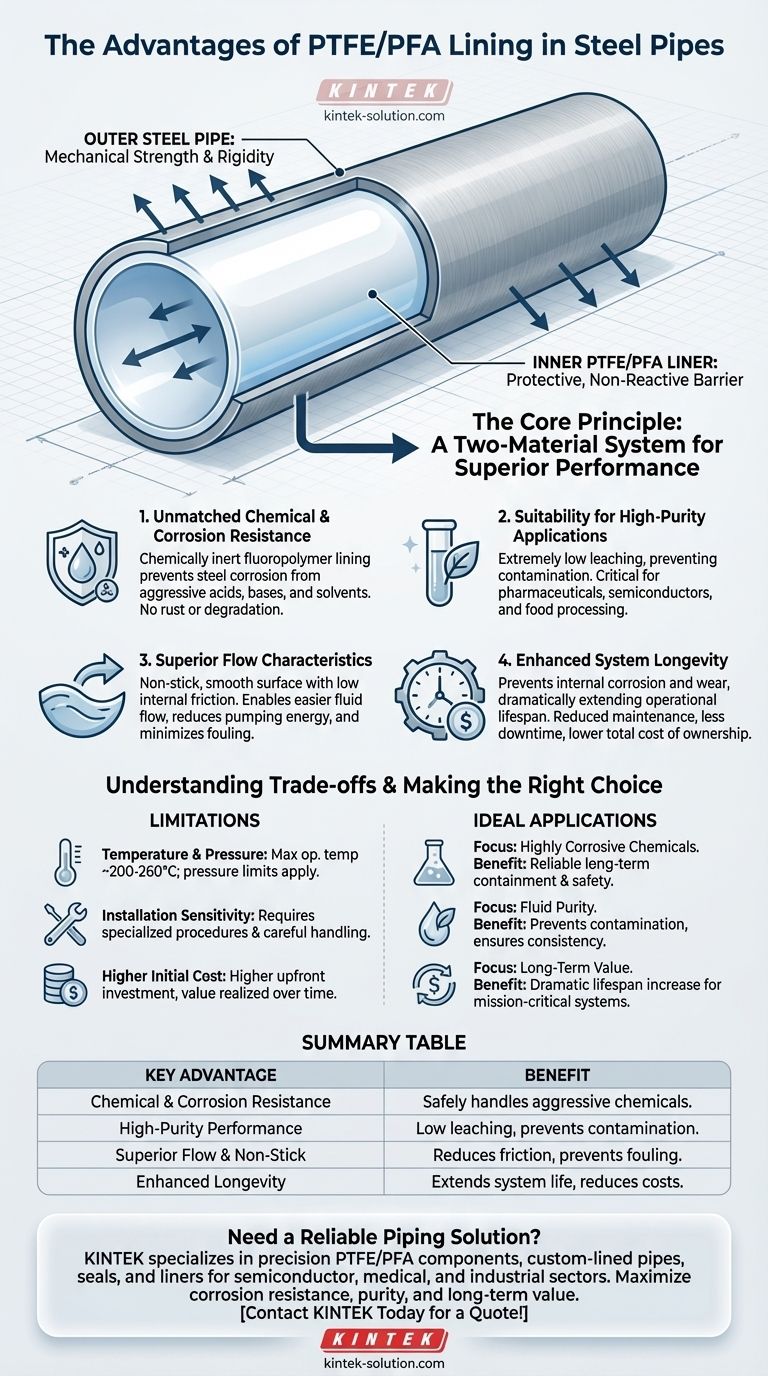

The Core Principle: A Two-Material System

To understand the benefits, it's essential to see the pipe not as a single material, but as a system where each component serves a distinct and vital purpose.

The Role of the Steel Exterior

The outer steel pipe provides the mechanical strength and rigidity of the system. It handles the physical stresses of pressure, installation, and the external plant environment. This ensures the piping remains stable and secure under demanding operational conditions.

The Function of the Fluoropolymer Liner

The internal PTFE/PFA liner is the component in direct contact with the process fluid. Its sole job is to provide a protective, non-reactive barrier, completely isolating the fluid from the structural steel.

Key Performance Advantages Explained

This two-material design delivers several distinct operational benefits that are impossible to achieve with either material alone.

Unmatched Chemical and Corrosion Resistance

The fluoropolymer lining is chemically inert to a vast range of substances, including aggressive acids, bases, and solvents. This prevents the steel pipe from ever being exposed to corrosive media, eliminating rust and chemical degradation as a failure mode.

Suitability for High-Purity Applications

PTFE/PFA liners have extremely low leaching characteristics. This means the pipe lining itself does not shed particles or chemicals into the fluid passing through it. This is critical for high-purity industries like pharmaceuticals, semiconductors, and food processing, where even trace contamination is unacceptable.

Superior Flow Characteristics

The liner's surface is exceptionally smooth and has non-stick properties, often referred to as low surface energy. This creates very little internal friction, which allows fluids to flow more easily and reduces the energy required for pumping. It also minimizes the risk of material buildup or fouling on the pipe walls.

Enhanced System Longevity

By preventing internal corrosion and wear, the liner dramatically extends the operational lifespan of the piping system. This leads to reduced maintenance requirements, less downtime, and a lower total cost of ownership compared to exotic metal alloys or less-resistant materials.

Understanding the Trade-offs

While highly effective, this technology is not a universal solution. An objective evaluation requires acknowledging its specific limitations.

Temperature and Pressure Boundaries

Fluoropolymers have a definitive maximum operating temperature (typically around 200-260°C or 400-500°F, depending on the specific material). Exceeding this can compromise the liner's integrity. The system's pressure rating is also a function of both the steel's strength and the liner's temperature.

Installation Sensitivity

Proper installation is critical. Flange connections must be made carefully to ensure a perfect seal without damaging the flared liner face. Specialized knowledge and procedures are required to prevent tears or cracks that would create a leak path and expose the steel to the process fluid.

Higher Initial Cost

PTFE/PFA-lined piping represents a higher upfront investment compared to standard carbon steel or some plastic systems. Its value is realized over time through its longevity and reduced maintenance in applications where other materials would fail quickly.

Making the Right Choice for Your Application

Selecting this piping system is a decision based on the specific demands of your process.

- If your primary focus is handling highly corrosive chemicals: The liner's near-universal chemical inertness provides the most reliable long-term containment, ensuring plant safety and asset protection.

- If your primary focus is maintaining fluid purity: The low-leaching and non-stick properties of the liner are essential for preventing product contamination and ensuring process consistency.

- If your primary focus is maximizing long-term value: The dramatic increase in system lifespan and reduction in maintenance often justifies the initial investment for mission-critical applications.

Ultimately, choosing PTFE/PFA-lined steel is an investment in system reliability, safety, and long-term operational performance.

Summary Table:

| Key Advantage | Benefit |

|---|---|

| Chemical & Corrosion Resistance | Safely handles aggressive acids, bases, and solvents. |

| High-Purity Performance | Low leaching prevents contamination in sensitive processes. |

| Superior Flow & Non-Stick | Smooth surface reduces friction and prevents fouling. |

| Enhanced Longevity | Protects steel, extending system life and reducing costs. |

Need a reliable piping solution for corrosive or high-purity applications?

KINTEK specializes in manufacturing precision PTFE and PFA components, including custom-lined pipes, seals, and liners. We serve the semiconductor, medical, laboratory, and industrial sectors, offering solutions from prototypes to high-volume production.

Our expertise ensures your system delivers maximum corrosion resistance, purity, and long-term value. Contact KINTEK today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- How do Teflon bushings benefit chemical processing plants? Enhance Reliability and Purity in Harsh Environments

- What makes PTFE an ideal sealing material overall? Superior Performance in Extreme Conditions

- What are the main features of PTFE bushings? Unlock Superior Performance in Harsh Environments

- What are the recommended applications for Teflon balls? Ideal Uses for Chemical Resistance & Low Friction

- What are the two most common materials used for backup rings? PTFE vs. PEEK for Superior Sealing

- What are the compression and recovery characteristics of expanded PTFE gaskets? Achieve Superior Sealing for Delicate Flanges

- What are the key benefits of using PTFE sheet material? Achieve Unmatched Performance in Extreme Conditions

- What are important final considerations when machining Teflon? Mastering PTFE for Precision and Safety