In a direct comparison, PTFE-free bushings are engineered for superior long-term durability and are less prone to degradation under high stress than their PTFE counterparts. While traditional PTFE bushings offer exceptional low-friction performance, they can break down over time, potentially leading to machinery damage and requiring more frequent replacement in demanding environments.

The choice between PTFE-free and PTFE bushings is a strategic engineering decision. It requires balancing the need for ultimate long-term durability against the requirement for the lowest possible coefficient of friction in a self-lubricating system.

The Case for PTFE-Free: Durability and Reliability

PTFE-free bushings are primarily designed to address the potential long-term failure points of traditional materials. Their value is centered on resilience and reducing the total cost of ownership.

Engineered for High-Stress Environments

PTFE-free variants are constructed to withstand significant operational stress over many years. This robust design prevents the material breakdown that can cause damage to shafts and other connected machinery components.

Reducing Long-Term Maintenance Costs

The extended lifespan directly translates to lower maintenance and replacement costs. By minimizing downtime and the need for new parts, these bushings offer significant long-term financial value, even if initial costs differ.

Environmental and Safety Advantages

The "PTFE-free" designation highlights their composition, which avoids certain chemicals. For businesses focused on sustainability or operating under strict environmental regulations, this is a critical design advantage.

Understanding the Strengths of PTFE Bushings

While their longevity can be a concern in certain applications, PTFE bushings remain an industry standard for valid reasons, primarily related to their unique surface properties.

Unmatched Low-Friction Performance

PTFE boasts an exceptionally low coefficient of friction. This makes it the ideal choice for applications where minimizing resistance and ensuring smooth, quiet sliding motion is the absolute top priority.

Self-Lubricating Operation

These bushings can operate completely dry, eliminating the need for external grease or oil. This "maintenance-free" characteristic is invaluable in applications where lubrication is impractical, difficult, or could contaminate the surrounding environment.

High Chemical and Temperature Resistance

PTFE is inherently resistant to a wide range of chemicals and moisture. It can also perform reliably across a high operating temperature range, making it suitable for many challenging industrial settings.

Understanding the Trade-offs: Longevity vs. Application

The decision to use one bushing over the other is not about which is "better" overall, but which is better for a specific task. The trade-off is fundamentally between mechanical durability and frictional performance.

The Failure Mode of PTFE

The primary longevity concern with PTFE bushings is material breakdown. Over time, especially under high loads or continuous high-velocity movement, the PTFE material can wear away or deform, leading to increased clearance and a loss of performance.

The Performance Profile of PTFE-Free

While designed for durability, a PTFE-free bushing may not inherently match the exceptionally low friction coefficient of a pure PTFE surface. The engineering focus is on creating a durable, long-lasting, low-friction surface, which may be a different priority than creating the lowest possible friction surface for a shorter-term application.

Cost Analysis: Upfront vs. Total Cost of Ownership

A PTFE bushing might offer a lower upfront cost and ideal performance for a low-load, high-precision device. However, a PTFE-free bushing provides superior long-term value in a high-stress industrial machine that runs 24/7 by preventing costly downtime and component replacement.

Making the Right Choice for Your Application

To select the correct bushing, you must align the material's core strengths with your primary engineering goal.

- If your primary focus is maximum operational lifespan and minimizing part replacement: Choose PTFE-free bushings, as they are engineered for superior durability and resilience in high-stress applications.

- If your primary focus is achieving the lowest possible friction in a self-lubricating system: A traditional PTFE bushing is the ideal choice for its unmatched sliding properties and maintenance-free dry operation.

- If your primary focus is long-term value and environmental compliance: PTFE-free bushings offer a sustainable and cost-effective solution by reducing replacement frequency and avoiding specific chemicals.

Ultimately, an informed decision depends on a clear understanding of your application's specific loads, speeds, and lifetime service requirements.

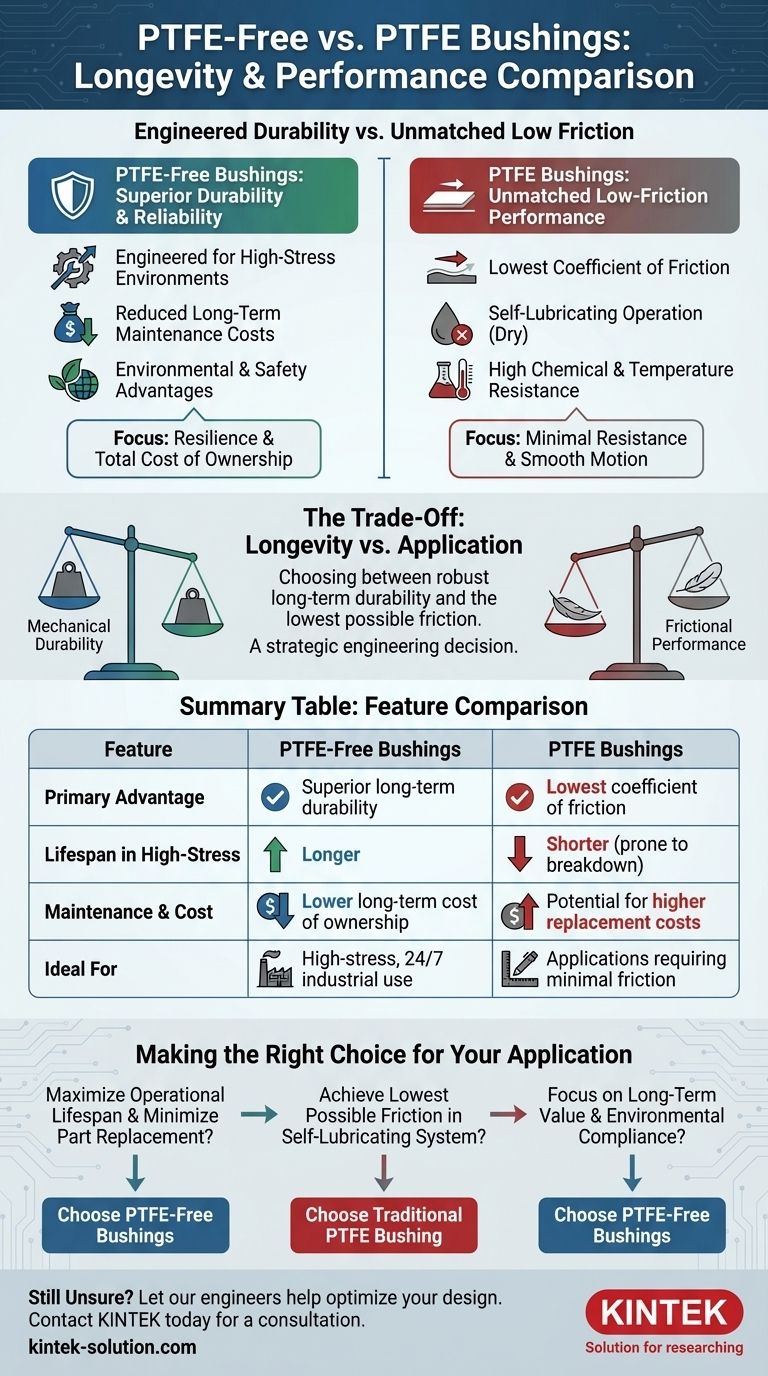

Summary Table:

| Feature | PTFE-Free Bushings | PTFE Bushings |

|---|---|---|

| Primary Advantage | Superior long-term durability | Lowest coefficient of friction |

| Lifespan in High-Stress | Longer | Shorter (prone to breakdown) |

| Maintenance & Cost | Lower long-term cost of ownership | Potential for higher replacement costs |

| Ideal For | High-stress, 24/7 industrial use | Applications requiring minimal friction |

Still Unsure Which Bushing is Right for Your Application?

Choosing between PTFE and PTFE-free bushings is a critical engineering decision that impacts your machine's performance, maintenance schedule, and total cost of ownership. KINTEK specializes in manufacturing high-performance PTFE components, including custom bushings, seals, and liners for the semiconductor, medical, laboratory, and industrial sectors.

Our expertise in precision production and custom fabrication—from prototypes to high-volume orders—ensures you get a component perfectly tailored to your specific loads, speeds, and environmental requirements.

Let our engineers help you optimize your design for longevity and performance. Contact KINTEB today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What is a Teflon sheet used for in heat press applications? The Essential Non-Stick Barrier

- What are some specific uses of PTFE in chemical handling? Enhance Safety and Reliability in Your Process

- Why are PTFE gaskets considered durable in harsh conditions? Unmatched Chemical & Temperature Resistance

- What are the tensile strength and elongation properties of PTFE O-rings? Key Metrics for Demanding Seals

- How does CNC turning work for PTFE, and what precautions are necessary? Achieve Precision Machining

- What is the conclusion regarding PTFE bellows as a material choice? Prioritize Chemical Inertness and Flexibility

- What are the key properties of PTFE washers? Ensure Reliability in Extreme Environments

- What are the key benefits of using PTFE gaskets? Achieve Unmatched Chemical & Temperature Resistance