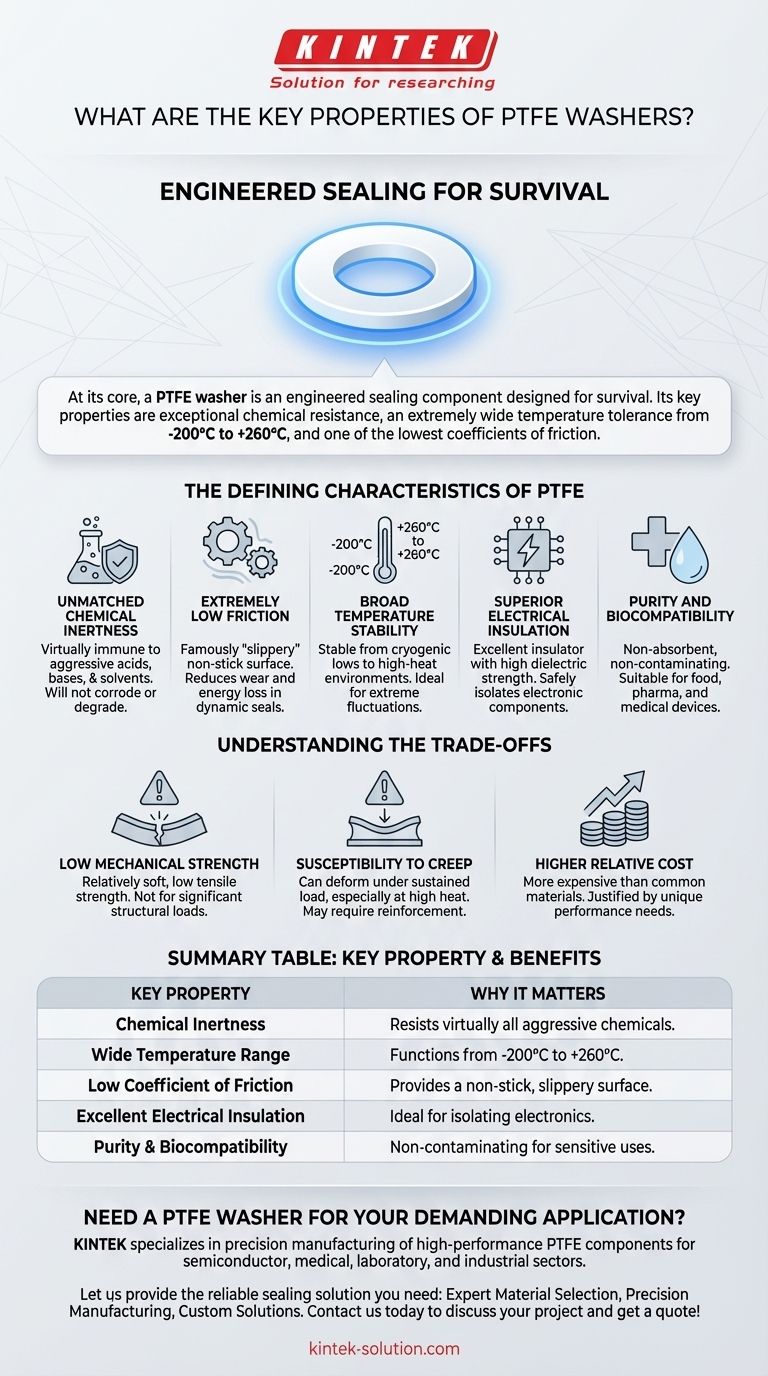

At its core, a PTFE washer is an engineered sealing component designed for survival. Its key properties are exceptional chemical resistance, an extremely wide temperature tolerance from -200°C to +260°C (-328°F to +500°F), and one of the lowest coefficients of friction of any solid material. These traits make it a definitive choice for reliability in harsh operational environments.

The decision to use a PTFE washer is not typically based on its mechanical strength, but on its unique ability to remain inert and functional in extreme chemical and thermal conditions where most other materials would quickly degrade and fail.

The Defining Characteristics of PTFE

To understand when and why to use Polytetrafluoroethylene (PTFE), we must look at its distinct properties. Each one solves a specific engineering challenge.

Unmatched Chemical Inertness

PTFE is virtually immune to chemical attack. It resists the most aggressive acids, bases, and solvents, making it invaluable in chemical processing, aerospace, and laboratory equipment.

This non-reactive nature ensures that the washer will not corrode, degrade, or contaminate the media it comes into contact with.

Extremely Low Friction

PTFE has a famously "slippery" or non-stick surface. This incredibly low coefficient of friction is critical in dynamic applications like seals, gaskets, and bearings.

This property prevents surfaces from adhering to the washer, which reduces operational wear, minimizes energy loss, and ensures smoother, more reliable movement.

Broad Temperature Stability

Few materials can match PTFE's operational temperature range. It remains stable and functional from cryogenic lows of -200°C (-328°F) up to high-heat environments of +260°C (+500°F).

This makes it a default choice for applications that experience extreme temperature fluctuations, from liquefied gas systems to high-temperature industrial processes.

Superior Electrical Insulation

PTFE is an excellent electrical insulator with high dielectric strength. It does not conduct electricity, which is essential for safely isolating electronic components.

This property is frequently leveraged in electrical and electronic applications to prevent short circuits and ensure signal integrity.

Purity and Biocompatibility

Because PTFE is non-absorbent, non-contaminating, and biocompatible, it is highly suitable for sensitive industries.

It is a standard material in food processing, pharmaceutical manufacturing, and medical devices where purity and preventing contamination are non-negotiable requirements.

Understanding the Trade-offs

While its properties are exceptional, PTFE is not the solution for every problem. Understanding its limitations is crucial for proper application and avoiding failure.

Low Mechanical Strength

PTFE is a relatively soft material. It does not possess the high tensile or compressive strength of metals or even many other engineering plastics.

It should not be chosen for applications where the washer's primary function is to bear a significant structural load.

Susceptibility to Creep

Under a constant, sustained load—especially at elevated temperatures—PTFE can slowly deform or "creep."

This tendency to cold-flow means it may not be suitable for high-pressure static sealing applications unless it is mechanically contained or reinforced with fillers (like glass or carbon).

Higher Relative Cost

Compared to common sealing materials like rubber or nylon, PTFE is more expensive.

Its use is best justified by application requirements where its unique chemical, thermal, or low-friction properties are essential for performance and longevity.

Making the Right Choice for Your Application

Selecting a PTFE washer depends entirely on the primary challenge you need to overcome in your design.

- If your primary focus is aggressive chemical exposure: PTFE is an industry-standard choice, providing a near-universal barrier against corrosion.

- If your primary focus is reducing friction and preventing sticking: The non-stick, low-friction surface of PTFE is ideal for dynamic seals and bearing applications.

- If your primary focus is extreme temperature stability: PTFE maintains its integrity in both cryogenic and high-heat environments where most elastomers and plastics would fail.

- If your primary focus is structural load-bearing: You should consider a different material or a filled-PTFE composite, as standard PTFE can creep under high pressure.

By understanding both its unique strengths and its practical limitations, you can leverage PTFE to ensure reliability in your most demanding applications.

Summary Table:

| Key Property | Why It Matters |

|---|---|

| Chemical Inertness | Resists virtually all aggressive acids, bases, and solvents. |

| Wide Temperature Range | Functions from -200°C to +260°C (-328°F to +500°F). |

| Low Coefficient of Friction | Provides a non-stick, slippery surface for dynamic applications. |

| Excellent Electrical Insulation | Ideal for isolating electronic components. |

| Purity & Biocompatibility | Non-contaminating for medical, food, and pharmaceutical uses. |

Need a PTFE Washer for Your Demanding Application?

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including seals, liners, and labware. We serve the semiconductor, medical, laboratory, and industrial sectors, providing custom fabrication from prototypes to high-volume orders.

Let us provide the reliable sealing solution you need:

- Expert Material Selection: Ensure your component performs under extreme chemical, thermal, and friction conditions.

- Precision Manufacturing: Achieve the exact specifications required for your application's success.

- Custom Solutions: Get parts tailored to your unique requirements, overcoming the limitations of standard PTFE.

Contact us today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments