In heat press applications, a Teflon sheet serves as a reusable, non-stick protective barrier. Placed between the hot upper platen of your press and your transfer design, it prevents ink from smudging or sticking to the heat source and shields the garment from scorching, ensuring a clean and professional result.

Think of a Teflon sheet not as an optional accessory, but as essential insurance for your heat press projects. It is the primary tool for preventing common failures like scorching and sticking, safeguarding both your garment and your equipment.

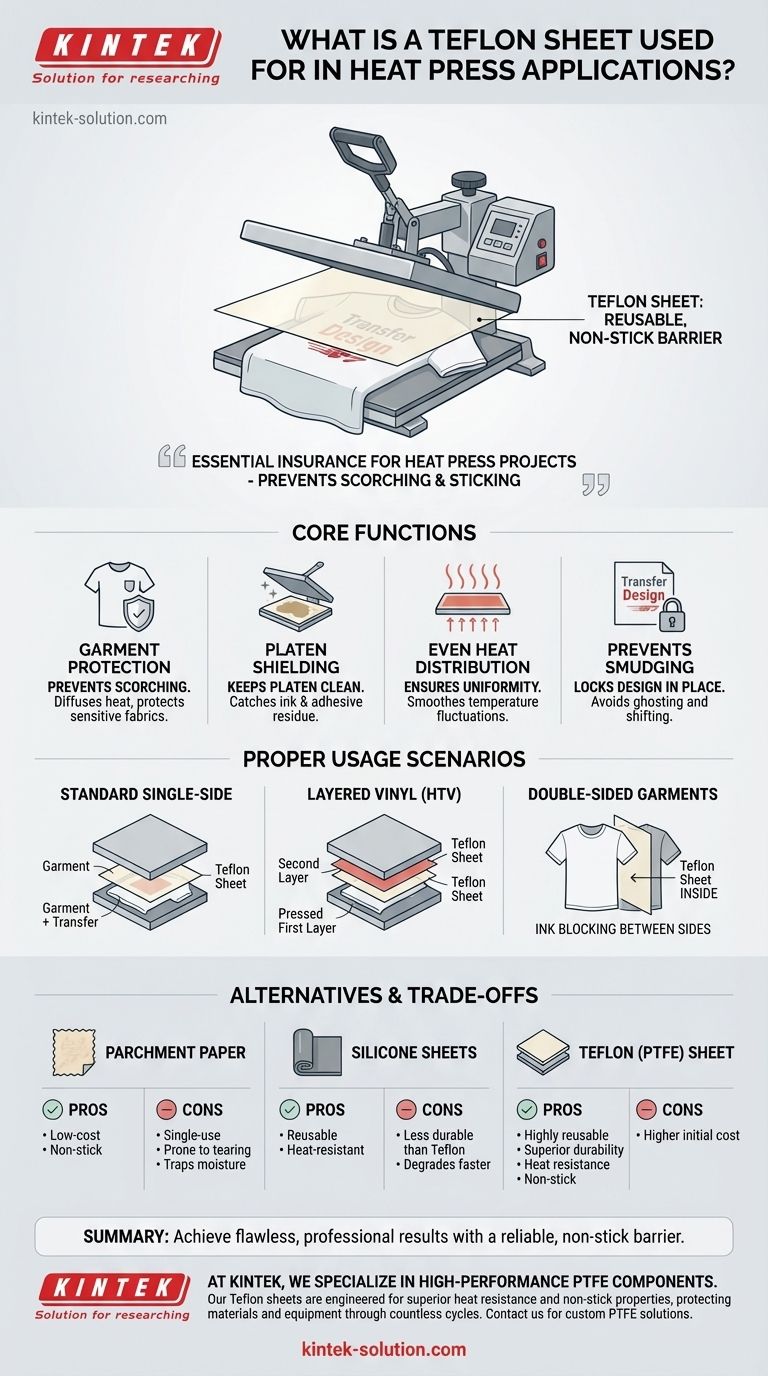

The Core Functions of a Teflon Sheet

A Teflon sheet performs several critical roles that contribute to a high-quality, repeatable heat transfer process. Understanding these functions clarifies why it is a staple for both hobbyists and professionals.

Protecting the Garment from Scorching

The most common failure in heat pressing is scorching, where the fabric yellows or discolors due to direct, intense heat. A Teflon sheet acts as a crucial buffer, diffusing the heat slightly and protecting sensitive or light-colored fabrics from burn marks.

Shielding the Heat Platen

During pressing, excess ink (especially in sublimation) or adhesive from heat transfer vinyl (HTV) can seep out. Without a protective layer, this residue bakes onto the hot platen, which is difficult to clean and can ruin subsequent projects. The non-stick Teflon surface catches this residue, keeping your expensive equipment clean.

Ensuring Even Heat Distribution

While a quality heat press should have even heating, a Teflon sheet helps smooth out any minor temperature fluctuations across the platen. This ensures that every part of your design receives consistent heat, leading to a more uniform and durable transfer.

Preventing Smudging and Ghosting

The slick surface of a Teflon sheet prevents the transfer paper from shifting or sticking to the platen when the press is opened. This small movement is a primary cause of "ghosting" or smudged images, and the sheet helps lock the design in place.

Proper Usage in Different Scenarios

How you use the sheet depends on the project. Applying it correctly maximizes its protective benefits.

For Standard Single-Side Transfers

This is the most common use. Simply place your garment and transfer design on the lower platen, then lay the Teflon sheet over the top of the transfer paper before closing the press.

For Layered Vinyl (HTV)

When applying multiple layers of vinyl, you must protect the layers you've already pressed. After applying the first layer, place the Teflon sheet over it before pressing the next layer on top. This prevents the direct heat from melting or damaging the exposed vinyl.

For Double-Sided Garments

To print on both sides of a shirt, place a Teflon sheet inside the garment. This creates an internal barrier that stops ink from the first side from being reactivated by the heat and bleeding through to the other side.

Understanding the Trade-offs and Alternatives

While highly recommended, it's important to understand the context and the other options available.

Is It Always Necessary?

While it is a best practice, it is not strictly required for every single project. Some durable fabrics or certain types of transfers may press successfully without one. However, the risk of ruining a garment or staining your platen is significantly higher, making the sheet a low-cost insurance policy.

Alternative 1: Parchment Paper

Parchment paper is a very common, low-cost alternative. It provides a non-stick surface but is a single-use item. It is prone to tearing and can sometimes trap moisture, which can negatively affect sublimation transfers.

Alternative 2: Silicone Sheets

Silicone-treated sheets are also reusable and heat-resistant. However, they are typically less durable than true Teflon (PTFE) sheets and may degrade more quickly over time. Teflon is generally considered the more robust, professional-grade solution for long-term use.

Making the Right Choice for Your Goal

Your decision to use a Teflon sheet or an alternative should be guided by your specific project goals and priorities.

- If your primary focus is professional quality and consistency: Always use a Teflon sheet. It is the industry standard for preventing common errors and protecting your investments.

- If your primary focus is minimizing initial costs: You can begin with parchment paper, but be aware of the risks and the need for constant replacement.

- If you are working with delicate or light-colored fabrics: A Teflon sheet is non-negotiable. The risk of scorching is too high to justify skipping this protective step.

Ultimately, incorporating a Teflon sheet into your workflow is the most reliable step toward achieving flawless, professional-grade results with every press.

Summary Table:

| Function | Benefit |

|---|---|

| Garment Protection | Prevents scorching and discoloration on fabrics. |

| Platen Shielding | Keeps the heat press clean from ink and adhesive residue. |

| Even Heat Distribution | Ensures a uniform, durable transfer every time. |

| Prevents Smudging | Locks the design in place to avoid ghosting. |

Achieve flawless, professional heat press results every time with a reliable, non-stick barrier.

At KINTEK, we specialize in manufacturing high-performance PTFE components, including durable Teflon sheets designed for the demanding environments of industrial and specialized applications. Our sheets are engineered for superior heat resistance and non-stick properties, ensuring they protect both your materials and your equipment through countless cycles.

Whether you are a professional in the garment decoration industry, a laboratory requiring precise thermal processing, or an industrial operation needing custom PTFE solutions, KINTEK provides the precision and durability you need. We offer custom fabrication from prototypes to high-volume orders.

Contact KINTEK today to discuss your specific needs and learn how our PTFE components can enhance your process and protect your investments.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments