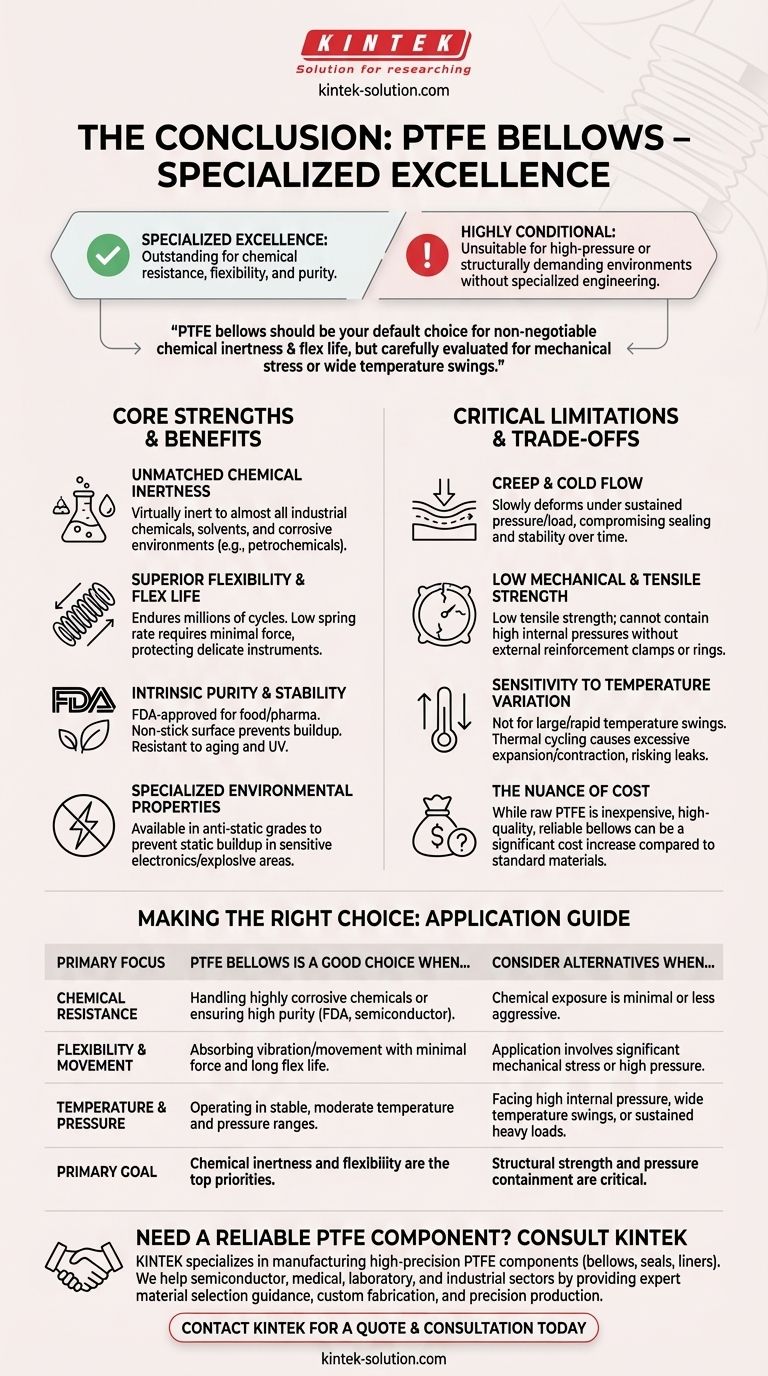

The definitive conclusion on PTFE bellows is one of specialized excellence. PTFE is an outstanding material choice for applications demanding extreme chemical resistance, flexibility, and purity. However, its suitability is highly conditional, as its inherent mechanical weaknesses make it unsuitable for high-pressure or structurally demanding environments without specific engineering and support.

PTFE bellows should be your default choice when chemical inertness and flex life are non-negotiable, but they must be carefully evaluated or avoided in applications with significant mechanical stress or wide temperature swings.

The Core Strengths of PTFE in Bellows Design

To understand if PTFE is the right choice, you must first appreciate its unique combination of properties where it has no equal.

Unmatched Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals and solvents. This makes it a first-choice material in highly corrosive environments.

Applications from petrochemical pipelines to aggressive chemical processing rely on PTFE's ability to perform without degradation.

Superior Flexibility and Flex Life

PTFE exhibits an excellent flex life, meaning it can endure millions of cycles of compression and extension without cracking or failing.

It also has a very low spring rate, which means it requires minimal force to move. This is critical for protecting delicate instruments or sensors from system vibration and movement.

Intrinsic Purity and Stability

PTFE is an inherently pure material and is FDA-approved for food and pharmaceutical contact. Its surfaces are also repellant, or non-stick, which prevents material buildup.

Furthermore, it is highly resistant to degradation from environmental factors like aging or UV radiation from sunlight, ensuring long-term stability.

Specialized Environmental Properties

For sensitive applications like semiconductor manufacturing or explosive environments, PTFE is available in anti-static grades.

This prevents the buildup of static electricity, protecting delicate electronic components and enhancing safety.

Understanding the Critical Trade-offs and Limitations

While its strengths are significant, PTFE's weaknesses are equally important. Ignoring them leads to component failure.

The Problem of Creep and Cold Flow

PTFE is a type of plastic that is subject to creep and cold flow. This means that under sustained pressure or load, the material can slowly and permanently deform.

This deformation can compromise sealing integrity and the overall dimensional stability of the bellow over time, especially in high-pressure applications.

Low Mechanical and Tensile Strength

Compared to metal or even many elastomers, PTFE has low tensile strength. It cannot contain high internal pressures without reinforcement.

For this reason, PTFE bellows used in pressure applications almost exclusively require high-pressure clamps or external reinforcement rings to provide structural support and prevent catastrophic failure.

Sensitivity to Temperature Variation

PTFE is not recommended for environments with large and rapid temperature variations.

Significant thermal cycling can cause the material to expand and contract excessively, impacting its sealing ability and leading to potential leaks.

The Nuance of Cost

While raw PTFE can be an inexpensive polymer, the manufacturing process for high-quality, reliable bellows can be costly.

When compared to standard rubber or metal bellows for less demanding applications, a specialized PTFE component can represent a significant cost increase.

Making the Right Choice for Your Application

Your decision must be guided by the single most critical demand of your system.

- If your primary focus is handling corrosive chemicals or ensuring high purity: PTFE is likely the superior, if not the only, viable choice due to its chemical inertness.

- If your primary focus is managing a high-pressure system: A reinforced metal or a robust elastomeric bellow will almost always be a more reliable and cost-effective solution.

- If your primary focus is absorbing vibration in a system with wide temperature fluctuations: You must carefully evaluate PTFE's limitations and may need to consider alternative materials like specialized composites or fluoroelastomers.

Ultimately, selecting PTFE is a strategic decision to prioritize its unparalleled chemical stability over its inherent mechanical limitations.

Summary Table:

| Key Consideration | PTFE Bellows: A Good Choice When... | Consider Alternatives When... |

|---|---|---|

| Chemical Resistance | Handling highly corrosive chemicals or requiring high purity (FDA, semiconductor). | Chemical exposure is minimal or less aggressive. |

| Flexibility & Movement | Absorbing vibration/movement with minimal force (low spring rate) and long flex life. | The application involves significant mechanical stress or high pressure. |

| Temperature & Pressure | Operating in stable, moderate temperature and pressure ranges. | Facing high internal pressure, wide temperature swings, or sustained heavy loads. |

| Primary Goal | Chemical inertness and flexibility are the top priorities. | Structural strength and pressure containment are critical. |

Need a Reliable PTFE Component for Your Demanding Application?

Selecting the right material is critical for performance and safety. At KINTEK, we specialize in manufacturing high-precision PTFE components, including custom bellows, seals, liners, and labware.

We help engineers and procurement specialists in the semiconductor, medical, laboratory, and industrial sectors solve complex challenges by:

- Providing expert material selection guidance to ensure your component meets the specific demands of your application.

- Offering custom fabrication from initial prototypes to high-volume production runs, ensuring a perfect fit and function.

- Prioritizing precision production to deliver components with the reliability and chemical resistance your processes require.

Let's discuss your project requirements and find the optimal solution. Contact our team today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What types of PTFE seals are used in the medical field? From O-rings to Spring-Energized Seals

- How does low friction benefit mechanical systems using PTFE washers? Boost Efficiency & Lifespan

- What is the primary function of PTFE pneumatic valves? Control Corrosive Media with Unmatched Reliability

- What does the machining process for PTFE parts involve? Mastering Precision for Soft, Heat-Sensitive Materials

- What role do Teflon PTFE sheets play in sewing projects? Achieve Flawless, Professional Results

- What is the PH range and temperature tolerance of pure PTFE gaskets? Master Extreme Chemical and Thermal Sealing

- What material is a PTFE liner made of? A Two-Part Composite for High-Performance Lubrication

- How do PTFE seals enhance sealing performance in ball valves? Achieve Superior, Leak-Proof Sealing