In short, the key benefits of PTFE gaskets are their extraordinary chemical resistance, broad temperature stability, and excellent non-stick properties. Polytetrafluoroethylene (PTFE) is a uniquely versatile sealing material that remains inert when exposed to the most aggressive acids, bases, and solvents, while performing reliably in conditions from cryogenic temperatures (-200°C) to high heat (+260°C).

The core value of a PTFE gasket is its ability to provide a reliable, non-contaminating seal in chemically aggressive and extreme-temperature environments where most other materials would fail. However, understanding its mechanical limitations, particularly creep, is essential for successful application.

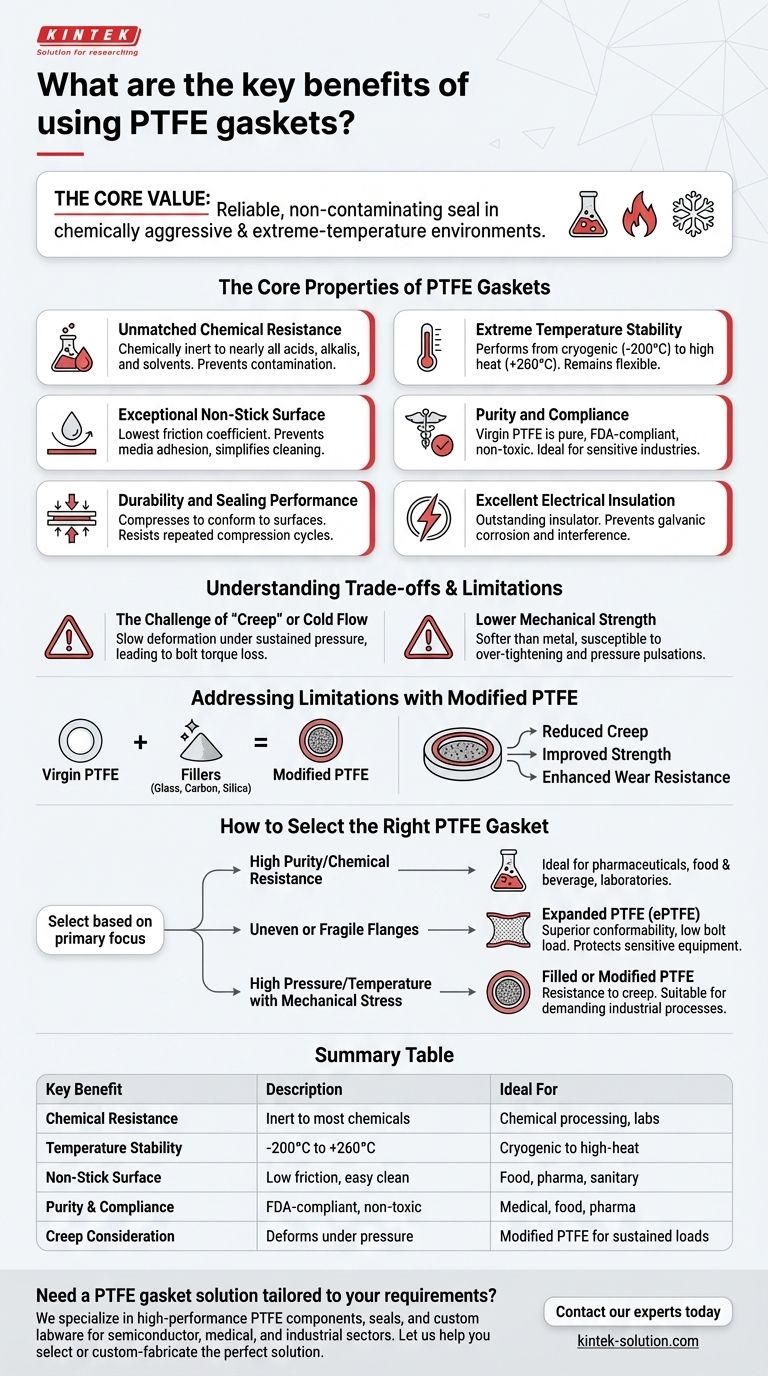

The Core Properties of PTFE Gaskets

To understand where PTFE excels, it's important to break down its primary characteristics. These properties work together to make it one of the most reliable choices for demanding industrial applications.

Unmatched Chemical Resistance

This is the most defining feature of PTFE. The material is chemically inert to nearly all industrial chemicals, including the most corrosive acids, alkalis, and solvents.

This near-universal resistance prevents the gasket from degrading, swelling, or contaminating the process media, ensuring both the integrity of the seal and the purity of the product.

Extreme Temperature Stability

PTFE gaskets maintain their properties across an exceptionally wide thermal range. They remain flexible and functional at cryogenic temperatures as low as -200°C (-328°F).

At the same time, they can withstand continuous service temperatures up to +260°C (+500°F), making them suitable for applications involving steam, hot oils, or other high-temperature processes.

Exceptional Non-Stick Surface

PTFE has one of the lowest coefficients of friction of any solid material, creating a non-stick, low-friction surface.

This property prevents process media from adhering to the gasket, which simplifies cleaning, reduces maintenance, and ensures easy removal of flanges without damaging the sealing surfaces.

Purity and Compliance

Virgin PTFE is inherently pure and free from contaminants. This makes it an ideal choice for sensitive industries like food processing, pharmaceuticals, and medical devices.

Many PTFE formulations are FDA-compliant, ensuring they are non-toxic and safe for contact with consumable products.

Durability and Sealing Performance

PTFE is a flexible material that can compress and conform to minor imperfections on flange surfaces, creating a tight and reliable seal against both liquids and gases.

Its durability allows it to withstand repeated compression cycles without significant degradation, contributing to a long service life.

Excellent Electrical Insulation

In its virgin form, PTFE is an outstanding electrical insulator. This property makes it valuable in applications where electrical isolation between flange components is required to prevent galvanic corrosion or interference.

Understanding the Trade-offs and Limitations

No material is perfect. While PTFE's chemical and thermal properties are elite, its mechanical properties present a critical trade-off that every engineer must consider.

The Challenge of "Creep" or Cold Flow

The most significant limitation of virgin PTFE is its tendency to exhibit creep, also known as cold flow. This is the process where the material slowly deforms permanently under sustained pressure, especially at elevated temperatures.

This deformation can lead to a loss of bolt torque over time, reducing the sealing pressure and potentially causing a leak. It is the primary reason why careful installation procedures and sometimes re-torquing are necessary.

Lower Mechanical Strength

Compared to metallic gaskets or even some other polymers, PTFE is a relatively soft material with lower tensile strength. It is more susceptible to damage from over-tightening or high-pressure system pulsations.

Addressing Limitations with Modified PTFE

To overcome the challenge of creep, manufacturers have developed modified PTFE materials. These gaskets are filled with substances like glass, carbon, or silica.

These fillers significantly reduce creep, improve mechanical strength, and enhance wear resistance, making them suitable for more demanding high-pressure and high-temperature services while retaining most of PTFE's chemical resistance. Expanded PTFE (ePTFE) is another common solution that offers excellent conformability with reduced creep.

How to Select the Right PTFE Gasket

Choosing the correct gasket depends entirely on the specific demands of your application.

- If your primary focus is high purity or universal chemical resistance: Virgin PTFE is an excellent choice for applications in pharmaceuticals, food and beverage, or labs where media purity is paramount.

- If your primary focus is sealing uneven or fragile flanges (e.g., glass-lined steel): Expanded PTFE (ePTFE) offers superior conformability with low bolt load requirements, protecting sensitive equipment.

- If your primary focus is high pressure or temperature with mechanical stress: Filled or modified PTFE gaskets provide the necessary resistance to creep and are better suited for demanding industrial processes.

Ultimately, leveraging PTFE's remarkable properties requires a clear understanding of both its strengths and its mechanical limitations.

Summary Table:

| Key Benefit | Description | Ideal For |

|---|---|---|

| Chemical Resistance | Inert to nearly all acids, bases, and solvents | Chemical processing, laboratories |

| Temperature Stability | Performs from -200°C to +260°C | Cryogenic to high-heat applications |

| Non-Stick Surface | Low friction, easy to clean | Food, pharmaceutical, and sanitary processes |

| Purity & Compliance | FDA-compliant, non-toxic | Medical, pharmaceutical, and food industries |

| Creep Consideration | Virgin PTFE may deform under pressure; modified PTFE available | Applications requiring sustained bolt load |

Need a PTFE gasket solution tailored to your specific chemical, temperature, or purity requirements?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including seals, gaskets, liners, and custom labware. Whether you're in the semiconductor, medical, laboratory, or industrial sector, we provide precision-engineered solutions—from prototypes to high-volume orders—that ensure reliability in the most aggressive environments.

Let us help you select or custom-fabricate the perfect PTFE gasket for your application. Contact our experts today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech