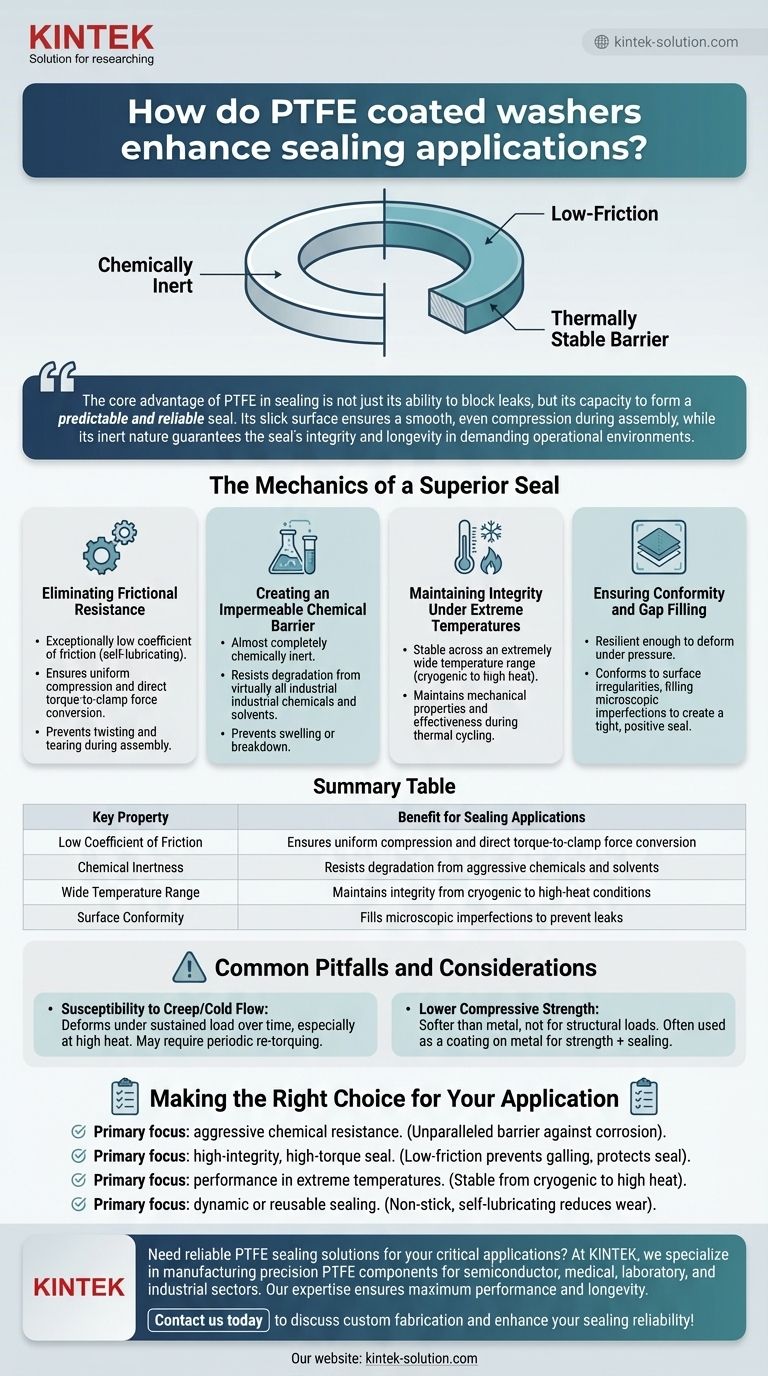

PTFE coated washers enhance sealing applications by creating a chemically inert, low-friction, and thermally stable barrier. This unique combination ensures that the full clamping force is applied directly to the seal without tearing or binding the material, while its resilience prevents degradation from harsh chemicals or extreme temperatures.

The core advantage of PTFE in sealing is not just its ability to block leaks, but its capacity to form a predictable and reliable seal. Its slick surface ensures a smooth, even compression during assembly, while its inert nature guarantees the seal's integrity and longevity in demanding operational environments.

The Mechanics of a Superior Seal

To understand why PTFE is so effective, we must look beyond its basic function as a barrier and examine its fundamental material properties. These properties work in concert to solve common sealing challenges.

Eliminating Frictional Resistance

The most distinctive feature of PTFE is its exceptionally low coefficient of friction—the lowest of any known solid.

When tightening a connection, this self-lubricating surface allows the washer to compress uniformly without twisting or tearing. This ensures that nearly all of the applied torque is converted directly into clamping force, creating a tight and consistent seal.

Creating an Impermeable Chemical Barrier

PTFE is almost completely chemically inert. It resists degradation from virtually all industrial chemicals, solvents, and corrosive agents.

This property guarantees that the washer will not swell, dissolve, or break down when in contact with aggressive media. It provides an effective barrier that protects the integrity of both the assembly and the fluid being sealed.

Maintaining Integrity Under Extreme Temperatures

Sealing materials often fail when they become brittle in the cold or soft in the heat.

PTFE maintains its excellent mechanical properties and stability across an extremely wide temperature range, from cryogenic conditions up to high heat. This resilience ensures the seal remains intact and effective during significant thermal cycling.

Ensuring Conformity and Gap Filling

A successful seal must perfectly fill any microscopic imperfections between the two mating surfaces.

PTFE is resilient enough to deform under pressure and conform to surface irregularities, effectively closing off potential leak paths for liquids or gases. This creates a tight, positive seal that prevents media from escaping.

Common Pitfalls and Considerations

While highly effective, PTFE is not a universal solution. Understanding its limitations is critical for proper application and avoiding premature failure.

Susceptibility to Creep

Under a sustained compressive load, especially at elevated temperatures, pure PTFE can be susceptible to "creep" or "cold flow."

This means the material can slowly deform over time, potentially reducing the clamping pressure on the joint. In critical applications, this may require periodic re-torquing of fasteners.

Lower Compressive Strength

Compared to metallic materials, PTFE is much softer. It is designed for sealing, not for bearing high structural loads.

Using a PTFE washer in an application where it is expected to provide significant structural strength can lead to material failure. Often, a metal washer with a PTFE coating is used to combine mechanical strength with sealing properties.

Making the Right Choice for Your Application

Choosing a sealing material depends entirely on the specific demands of your environment. PTFE excels where other materials fail due to its unique combination of properties.

- If your primary focus is aggressive chemical resistance: PTFE's inertness provides an unparalleled barrier against corrosion and media contamination.

- If your primary focus is a high-integrity, high-torque seal: The low-friction surface prevents galling and ensures torque translates directly into clamping force, protecting the seal from damage during assembly.

- If your primary focus is performance in extreme temperatures: PTFE's stability from cryogenic lows to high heat makes it one of the most versatile and reliable choices.

- If your primary focus is dynamic or reusable sealing: The non-stick, self-lubricating properties reduce wear in moving parts and allow for easier disassembly and maintenance.

Ultimately, leveraging PTFE washers is a decision for predictable performance and long-term reliability in your most critical sealing applications.

Summary Table:

| Key Property | Benefit for Sealing Applications |

|---|---|

| Low Coefficient of Friction | Ensures uniform compression and direct torque-to-clamp force conversion |

| Chemical Inertness | Resists degradation from aggressive chemicals and solvents |

| Wide Temperature Range | Maintains integrity from cryogenic to high-heat conditions |

| Surface Conformity | Fills microscopic imperfections to prevent leaks |

Need reliable PTFE sealing solutions for your critical applications?

At KINTEK, we specialize in manufacturing precision PTFE components, including seals, liners, and labware, tailored for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your sealing applications achieve maximum performance, longevity, and chemical resistance.

Contact us today to discuss custom fabrication from prototypes to high-volume orders and enhance your sealing reliability!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- Why is chemical inertness important for PTFE coated fasteners? Ensure Long-Term Reliability in Harsh Environments

- Why is PTFE resistant to chemicals? The Science Behind Its Unmatched Inertness

- What are the key considerations for fixturing PTFE during machining? Master Soft Material Handling for Precision

- What electrical properties do PTFE mechanical seals possess? Superior Insulation for Demanding Applications

- What factors determine the choice of insert material for PTFE envelope gaskets? Select the Right Core for Pressure & Performance

- How is PTFE rod applied in the food preparation industry? Unlock Safer, More Efficient Food Processing

- What are the core material options for PTFE encapsulated O-rings? Choose Viton® or Silicone for Your Sealing Needs

- What are the benefits of PTFE sealed ball bearings? Achieve Peak Performance with Low Friction & Zero Maintenance