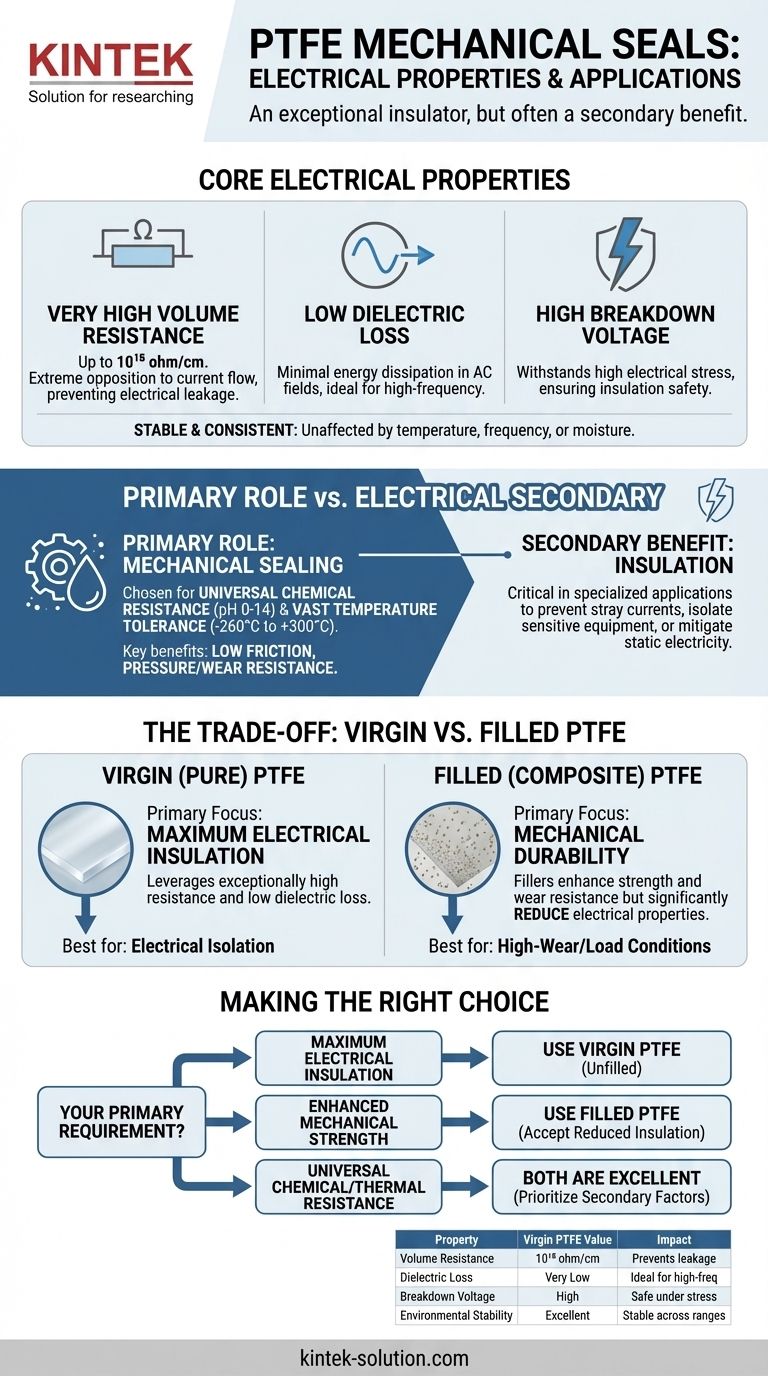

In short, Polytetrafluoroethylene (PTFE) is an exceptional electrical insulator. Its key electrical properties include an extremely high volume resistance of up to 10¹⁸ ohm/cm, a low dielectric loss, and a high breakdown voltage. Crucially, these characteristics remain stable and are largely unaffected by changes in frequency, temperature, or other environmental factors.

The core takeaway is that while PTFE's electrical insulation is among the best of any plastic, this property is typically a secondary benefit in mechanical seal applications. The primary reasons for selecting PTFE are almost always its unparalleled chemical resistance, wide temperature tolerance, and low coefficient of friction.

Deconstructing PTFE's Electrical Insulation Capabilities

To understand why PTFE is considered a premier electrical insulator, we need to look at its specific metrics. These properties make it a reliable choice for applications where electrical isolation is a concern.

Exceptionally High Volume Resistance

PTFE’s volume resistance of 10¹⁸ ohm/cm is one of the highest values known for a solid material. This means it provides extreme opposition to the flow of electrical current through its bulk. In practical terms, it almost completely prevents electrical leakage.

Low Dielectric Loss

This property means that when PTFE is subjected to an alternating electric field, it absorbs and dissipates very little energy. This is a critical advantage in high-frequency applications, where materials with high dielectric loss can generate unwanted heat and cause signal degradation.

High Breakdown Voltage

Breakdown voltage is the maximum voltage a material can withstand before it fails and conducts electricity. PTFE's high rating provides a significant safety margin, ensuring it maintains its insulating properties even when exposed to high electrical stress.

Unmatched Environmental Stability

A key advantage of PTFE is the stability of its electrical properties. They show minimal change across a wide range of temperatures and frequencies, and are not affected by moisture. This consistency makes PTFE a highly reliable insulator in dynamic or harsh operating environments.

Why Electrical Properties Matter (and When They Don't)

While a seal's primary job is to prevent leaks, its material properties can have secondary effects that are critical in certain systems. Understanding the context of the application is key.

The Primary Role of a Mechanical Seal

First and foremost, a mechanical seal is chosen for its ability to contain a fluid under specific pressures and temperatures. PTFE, often called the "king of plastics," excels here due to its near-universal chemical inertness (pH 0-14) and vast operating temperature range (-260°C to +300°C).

When Insulation is a Critical Secondary Function

In some specialized applications, PTFE's electrical properties become a significant advantage. This can include preventing stray electrical currents from damaging bearings or other components, isolating electrically sensitive equipment, or mitigating static electricity buildup in certain fluid handling systems.

When Other Properties Take Precedence

For the vast majority of mechanical seal applications, PTFE is selected for its other world-class features:

- Low Friction: Its extremely low coefficient of friction reduces wear and heat generation, increasing seal life and efficiency.

- Chemical Resistance: It can handle nearly any chemical medium, from strong acids to strong oxidizing agents.

- Pressure and Wear Resistance: It maintains its integrity in high-pressure and reciprocating applications.

In these cases, its excellent electrical insulation is simply a valuable, and often welcome, side benefit.

Understanding the Trade-offs: Virgin vs. Filled PTFE

Not all PTFE is the same. Additives, or "fillers," are often used to enhance specific mechanical properties, but this comes with a direct impact on its electrical performance.

The Purpose of Fillers

Pure, or virgin, PTFE is relatively soft. To improve its mechanical strength, wear resistance, and stability under heavy loads, fillers like glass fiber, carbon, or bronze are added to create a composite material.

How Fillers Compromise Electrical Insulation

This is the critical trade-off. While fillers enhance mechanical durability, they almost always degrade PTFE's elite electrical properties. Conductive fillers like carbon, for instance, will drastically lower the material's volume resistance, transforming it from a top-tier insulator into a semi-conductive material.

Mechanical Strength vs. Electrical Purity

The choice between virgin and filled PTFE creates a clear decision point. If you need the absolute best electrical insulation, virgin PTFE is the only option. If the seal must withstand extreme loads or high wear, a filled PTFE is necessary, but you must accept the compromise in electrical performance.

Making the Right Choice for Your Application

Your final material selection depends entirely on the primary demand of your system.

- If your primary focus is maximum electrical insulation: You must use virgin (unfilled) PTFE to leverage its exceptionally high volume resistance and low dielectric loss.

- If your primary focus is mechanical durability for high-wear or high-load conditions: Select a filled PTFE, but be fully aware that its electrical insulation properties will be significantly reduced.

- If your primary focus is universal chemical and thermal resistance: Both virgin and many filled PTFE variants will perform exceptionally, allowing you to prioritize secondary factors like pressure or wear.

Ultimately, understanding the interplay between PTFE's mechanical and electrical properties empowers you to select the precise material for optimal performance and reliability.

Summary Table:

| Property | Virgin PTFE Value | Impact on Seal Performance |

|---|---|---|

| Volume Resistance | Up to 10¹⁸ ohm/cm | Extreme opposition to electrical current flow, prevents leakage |

| Dielectric Loss | Very Low | Minimal energy dissipation in AC fields, ideal for high-frequency use |

| Breakdown Voltage | High | Maintains insulation under high electrical stress for safety |

| Environmental Stability | Excellent | Properties remain stable across wide temperature/frequency ranges |

Need a PTFE Seal with Superior Electrical Insulation or Mechanical Durability?

Whether your primary requirement is maximum electrical insulation with virgin PTFE or enhanced mechanical strength with a filled compound, KINTEK has the expertise to deliver. We manufacture precision PTFE components (seals, liners, labware) for the semiconductor, medical, laboratory, and industrial sectors, offering custom fabrication from prototypes to high-volume orders.

Contact our experts today to discuss your application and get the right PTFE solution for optimal performance and reliability.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What makes PTFE stand out among materials used in sealing technology? Unmatched Chemical & Thermal Resistance

- What is the overall operating temperature range for PTFE seals, gaskets, and O-rings? Achieve Sealing Integrity from -200°C to +260°C

- What are the key steps for properly installing PTFE seals? Ensure a Leak-Free, Long-Lasting Seal

- What are the benefits of using PTFE seals in demanding industries? Solve Extreme Sealing Challenges

- How do FEP and PTFE encapsulated O-rings contribute to equipment longevity? Prevent Costly Downtime with Superior Seals