Yes, Polytetrafluoroethylene (PTFE) rod is a critical material in the food preparation industry. Its use is driven by a unique combination of properties that make it ideal for direct and indirect food contact, from large-scale industrial processing down to consumer kitchenware. It is most commonly valued for its non-stick surfaces, high heat resistance, and chemical inertness.

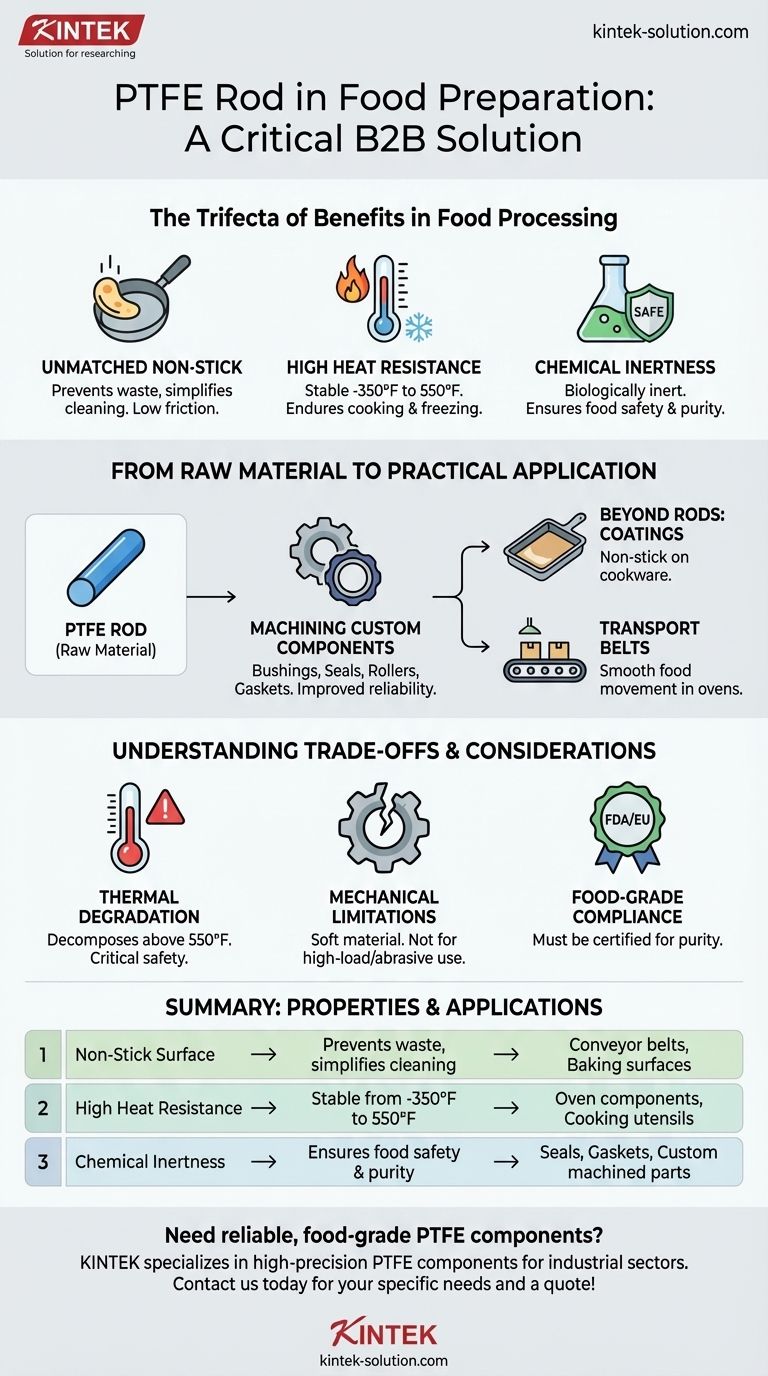

The core reason PTFE is indispensable in food preparation is its trifecta of benefits: its famous non-stick quality prevents waste and simplifies cleaning, its high-temperature stability endures baking and cooking processes, and its chemical inertness ensures food safety and purity.

The Core Properties Driving Food Industry Adoption

To understand PTFE's role, we must look at the specific material characteristics that solve key challenges in food handling and processing.

Unmatched Non-Stick Performance

The most well-known property of PTFE is its extremely low coefficient of friction, making it one of the most slippery materials known.

In food processing, this means products like dough, confectionery, and baked goods release easily from surfaces. This dramatically reduces food waste and makes equipment much easier to clean.

Exceptional Temperature Stability

PTFE maintains its integrity across a vast temperature range, typically from -350°F to 550°F (-212°C to 288°C).

This allows it to be used in equipment for both cooking and flash-freezing processes without degrading, becoming brittle, or leaching chemicals.

Chemical Inertness and Food Safety

PTFE is biologically inert, meaning it does not react with food acids, oils, or cleaning agents.

This property is fundamental to its role in the food industry. It ensures that the material will not contaminate food, alter its taste, or introduce harmful substances, making it a safe choice for direct food contact when certified as food-grade.

From Raw Material to Practical Application

While you asked specifically about "rod," it's important to understand that the rod is often the starting point for creating more complex parts or is used alongside other forms of PTFE.

Machining Rods into Custom Components

PTFE rods are an excellent raw material for machining custom parts.

Engineers use them to create components like bushings, seals, rollers, and gaskets for food processing machinery. These parts benefit from PTFE's low friction and wear resistance, improving equipment reliability and longevity.

Beyond Rods: Coatings and Transport Belts

The same properties found in PTFE rod are leveraged in other forms. PTFE is famously used as a non-stick coating on consumer cookware and commercial bakeware.

In large-scale production, PTFE-coated sheets and fabric belts are used as conveyors in ovens and cooling tunnels, ensuring food moves smoothly through the production line without sticking.

Understanding the Trade-offs and Considerations

While highly effective, PTFE is not without its limitations. An objective assessment requires understanding its operational boundaries.

Thermal Degradation Concerns

Although it has high heat resistance, exceeding its maximum recommended temperature (around 550°F or 288°C) can cause the material to decompose. This is a critical safety consideration in designing and operating any equipment.

Mechanical Limitations

PTFE is a relatively soft material. It has excellent low-friction properties but is not suitable for high-load or highly abrasive applications unless it is filled or reinforced with other materials like glass or carbon.

Ensuring Food-Grade Compliance

It is essential to source PTFE that is explicitly certified as food-grade (e.g., FDA or EU compliant). This certification ensures the material is manufactured to ultra-pure standards, free from pigments or recycled materials that are not safe for food contact.

Making the Right Choice for Your Goal

Your application will determine how you should leverage PTFE.

- If your primary focus is consumer cookware or utensils: A PTFE coating is the most effective application for creating durable, non-stick surfaces.

- If your primary focus is industrial food processing: Use machined components from PTFE rod for reliable machine parts and PTFE-coated belts for efficient product transport.

- If your primary focus is food safety and purity: Always source certified food-grade PTFE and operate all equipment well within the material's specified temperature limits.

Ultimately, leveraging PTFE's unique properties allows for safer, more efficient, and higher-quality food production.

Summary Table:

| Property | Benefit in Food Industry | Common Application |

|---|---|---|

| Non-Stick Surface | Prevents food waste, simplifies cleaning | Conveyor belts, baking surfaces |

| High Heat Resistance | Stable from -350°F to 550°F | Oven components, cooking utensils |

| Chemical Inertness | Ensures food safety and purity | Seals, gaskets, custom machined parts |

Need reliable, food-grade PTFE components for your application?

KINTEK specializes in manufacturing high-precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. We prioritize precision production and offer custom fabrication from prototypes to high-volume orders, ensuring your food processing equipment meets the highest standards of safety and efficiency.

Contact us today to discuss your specific needs and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What factors affect the lifespan of PTFE tubing and rods? Ensure Long-Term Reliability for Your Critical Applications

- What are the temperature limits for PTFE in machining applications? Managing Thermal Expansion for Precision Parts

- What are the common applications of PTFE beyond non-stick cookware? Unlock High-Performance Solutions

- Where are piston seals mainly used? Essential for Hydraulic & Pneumatic Systems

- What role do PTFE gaskets play in the food and beverage industry? Ensuring Purity and Compliance

- How can PTFE be customized for specific applications? Tailor Performance with Fillers & Fabrication

- What is virgin PTFE sheet and how is it different from Teflon? | Choosing the Right Grade for Your Application

- Why is regular inspection of PTFE gaskets necessary? Ensure Safety and Prevent Costly Leaks