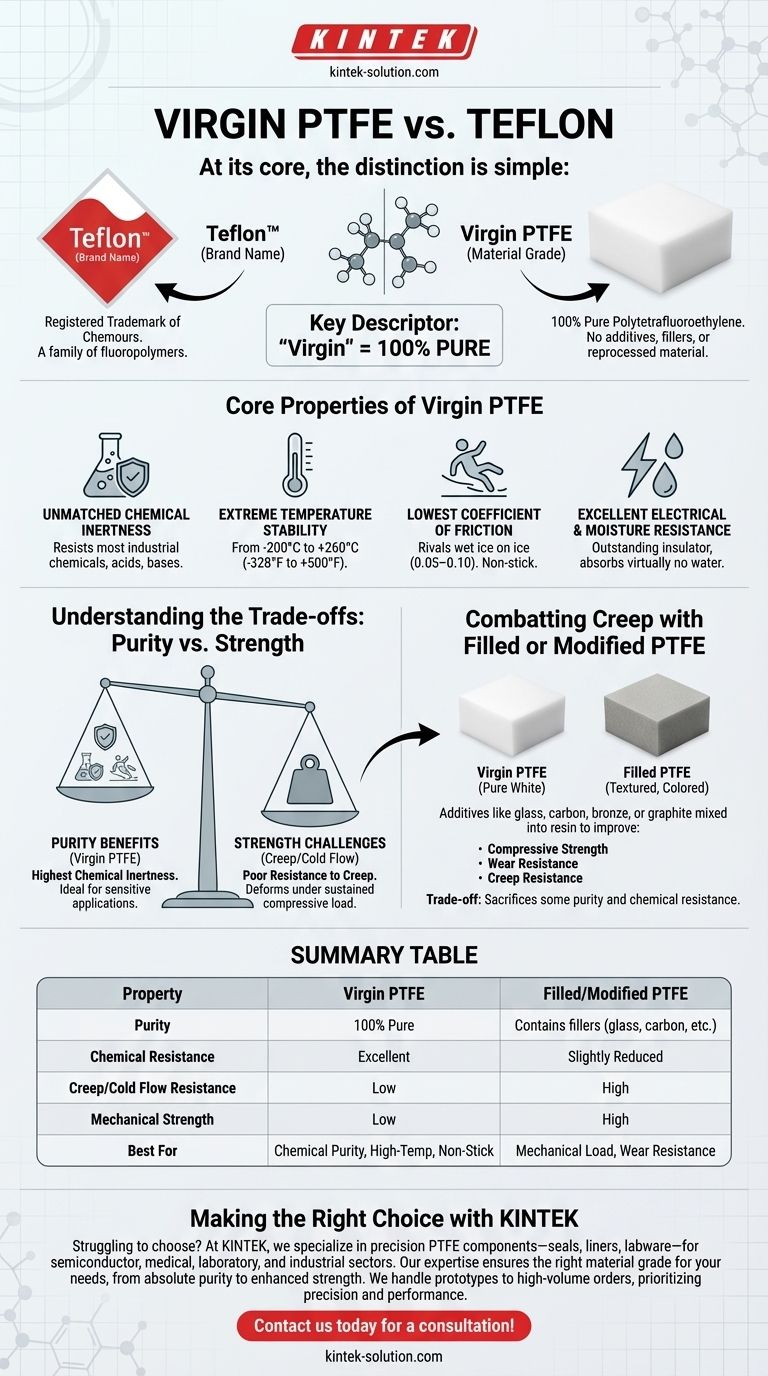

At its core, the distinction is simple: Teflon is a brand name, while virgin Polytetrafluoroethylene (PTFE) is a specific, pure grade of the material that Teflon sells. There is no chemical difference between a virgin PTFE resin sold under the Teflon™ brand and one sold by another manufacturer. The term "virgin" is the critical descriptor, indicating the PTFE is 100% pure, containing no reprocessed material or functional additives.

The real choice isn't between "Teflon" and "PTFE," but between different grades of PTFE. Virgin PTFE offers the highest chemical purity and inertness, but this comes at the cost of mechanical strength compared to filled or modified grades.

What is Virgin PTFE? A Foundational Guide

The PTFE vs. Teflon Distinction

The name Teflon™ is the registered trademark of The Chemours Company for its family of fluoropolymer products, the most famous of which is PTFE.

Because of its market dominance for decades, the brand name "Teflon" became synonymous with the material itself, much like "Kleenex" is used for tissues. However, many companies manufacture PTFE, and "virgin PTFE" refers to the pure grade regardless of the manufacturer.

Defining "Virgin" Grade

In material science, "virgin" signifies that the plastic is created directly from the source polymer resin. It contains no recycled content, fillers, or reinforcing agents.

This 100% pure composition gives virgin PTFE its characteristic bright white appearance and its most valued properties, particularly for sensitive applications.

The Core Properties of Virgin PTFE

The purity of virgin PTFE gives it a unique and powerful combination of characteristics.

Unmatched Chemical Inertness

Virgin PTFE is almost completely inert, meaning it will not react with the vast majority of industrial chemicals, acids, or bases. This makes it a go-to material for seals, gaskets, and linings in aggressive chemical environments.

Extreme Temperature Stability

This material maintains its properties across an exceptionally wide service temperature range, from a cryogenic -200°C (-328°F) up to a continuous +260°C (+500°F). It has a high melting point of around 327°C (621°F).

The Lowest Coefficient of Friction

With a coefficient of friction rivaling that of wet ice on ice (0.05–0.10), virgin PTFE is one of the most slippery solid materials known. This "non-stick" quality is fundamental to its use in everything from cookware to low-friction bearings.

Excellent Electrical and Moisture Resistance

Virgin PTFE is an outstanding electrical insulator (dielectric) and absorbs virtually no water. This makes it ideal for high-frequency electronics and components that must remain stable in humid environments.

Understanding the Trade-offs: Purity vs. Strength

While its purity provides many benefits, it is also the source of its primary limitation. Choosing virgin PTFE requires understanding this critical trade-off.

The Challenge of "Creep" or Cold Flow

The most significant weakness of virgin PTFE is its poor resistance to creep, also known as cold flow. This is the tendency of the material to slowly deform or "flow" away when subjected to a sustained compressive load, even at room temperature.

For applications involving high-pressure seals or constant mechanical loading, virgin PTFE may deform over time, leading to failure.

When to Consider Filled or Modified PTFE

To combat creep and improve mechanical properties, manufacturers create filled or modified grades of PTFE. Additives like glass, carbon, bronze, or graphite are mixed into the PTFE resin.

These fillers dramatically increase the material's compressive strength, wear resistance, and resistance to creep. However, they do so by sacrificing some of the chemical resistance and absolute purity of the virgin grade.

Making the Right Choice for Your Application

Your final decision must be guided by the single most important requirement for your project.

- If your primary focus is maximum purity and chemical resistance: Choose virgin PTFE, especially for applications in pharmaceutical, food and beverage, or semiconductor manufacturing.

- If your primary focus is mechanical stability under load: Choose a filled PTFE grade (e.g., glass-filled or carbon-filled) to prevent failure from creep and wear.

- If your primary focus is a general-purpose, low-friction surface: Virgin PTFE is often an excellent choice, but you must account for its inherent softness and potential to deform under pressure.

Understanding this distinction empowers you to select a material based on its specific grade and properties, not just its brand name.

Summary Table:

| Property | Virgin PTFE | Filled/Modified PTFE |

|---|---|---|

| Purity | 100% Pure | Contains fillers (glass, carbon, etc.) |

| Chemical Resistance | Excellent | Slightly Reduced |

| Creep/Cold Flow Resistance | Low | High |

| Mechanical Strength | Low | High |

| Best For | Chemical Purity, High-Temp, Non-Stick | Mechanical Load, Wear Resistance |

Struggling to choose between virgin PTFE and a filled grade for your specific application?

At KINTEK, we specialize in manufacturing precision PTFE components—from custom seals and liners to labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures you get the right material grade, whether you need the absolute purity of virgin PTFE for sensitive processes or the enhanced strength of filled grades for demanding mechanical loads.

We handle everything from prototypes to high-volume orders, prioritizing precision and performance. Let our team help you optimize your design and material selection—contact us today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the properties of stainless steel-filled PTFE? Enhance Load & Wear Resistance for Demanding Applications

- In what types of industrial applications are PTFE-lined butterfly valves versatile? Handle Aggressive & Pure Media

- Why is PTFE preferred in CNC machining for product design? Unlock High-Performance Components

- How does the flexibility of Teflon bellow seals benefit their performance? Ensure Leak-Proof Sealing in Demanding Conditions

- What materials are used in PTFE slide bearing plates? Choose the Right Bearing for Your Application

- What benefits does the low friction coefficient of PTFE provide for fasteners? Enhance Assembly & Prevent Seizing

- Why is ePTFE preferred over PTFE in certain applications? Unlock Superior Sealing & Filtration

- What are the tolerance specifications for the thickness of PTFE disks? Why ±20% is the Industry Standard