At their core, piston seals are designed for one primary environment. They are the fundamental sealing components within hydraulic and pneumatic cylinders. Their critical function is to seal the space between a moving piston and the cylinder bore, preventing fluid or gas leakage and ensuring pressure is maintained for the system to operate effectively.

While their use spans countless industries—from construction equipment to space exploration—the underlying principle is constant. Piston seals are the component that enables linear motion in fluid power systems by containing and converting fluid pressure into mechanical force.

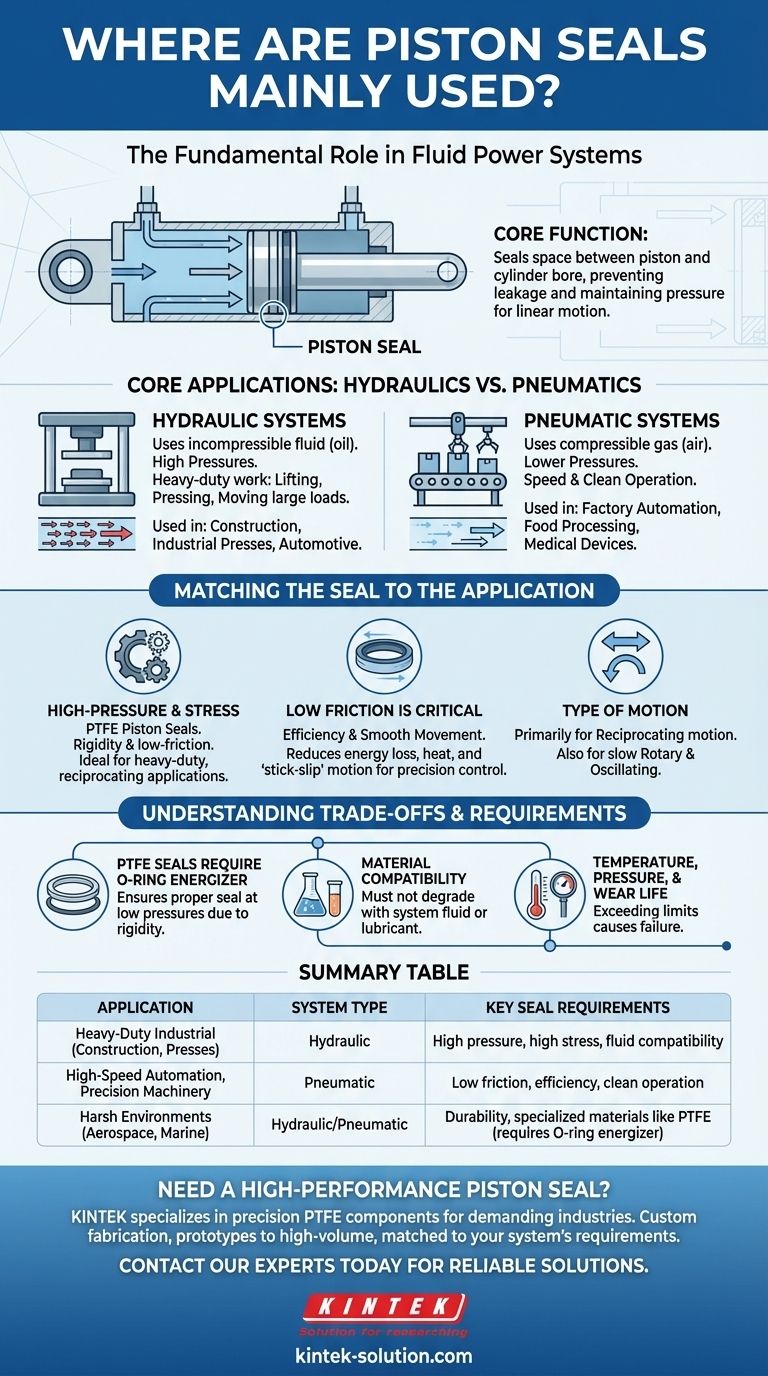

The Fundamental Role in Fluid Power Systems

To understand where piston seals are used, we must first understand the systems they enable. These seals are not standalone parts; they are integral to actuators that generate movement and power.

What is a Piston Seal?

A piston seal is a type of dynamic seal that fits into a groove on the outer diameter of a piston. It forms a pressure barrier against the inner wall, or bore, of a cylinder.

This prevents the pressurized fluid or gas from bypassing the piston head as it moves back and forth. This containment of pressure is what allows the system to generate force.

The Core Applications: Hydraulics vs. Pneumatics

The two main categories of systems where piston seals are indispensable are hydraulic and pneumatic.

Hydraulic systems use an incompressible fluid, like oil, to transmit power. These systems operate at very high pressures and are used for heavy-duty work like lifting, pressing, and moving large loads. You find them in construction equipment, industrial presses, and automotive machinery.

Pneumatic systems use a compressible gas, like air, to transmit power. They typically operate at much lower pressures than hydraulics but are valued for their speed and clean operation. They are common in factory automation, food processing, and medical device manufacturing.

Matching the Seal to the Application

Not all piston seals are the same. The choice of seal material and design is dictated entirely by the demands of the specific system it will operate in.

High-Pressure and High-Stress Environments

For the most demanding hydraulic or pneumatic systems, specialized materials are required. PTFE (polytetrafluoroethylene) piston seals are utilized where high pressure and significant mechanical stress are expected.

Their rigidity and low-friction properties make them ideal for heavy-duty, reciprocating applications where durability is paramount.

When Low Friction is Critical

In many pneumatic and some hydraulic applications, efficiency and smooth movement are the top priorities. Low-friction piston seals are designed specifically for these linear and reciprocating dynamic sealing tasks.

Minimizing friction reduces energy loss, heat generation, and jerky "stick-slip" motion, which is crucial for precision control systems.

The Type of Motion Matters

Piston seals are primarily designed for reciprocating motion—a repeated back-and-forth linear movement inside a cylinder.

However, some specialized designs are also suitable for slow rotary and slow oscillating applications, such as in certain valve actuators or swivel joints.

Understanding the Trade-offs and System Requirements

Selecting a piston seal is not just about its primary function; it involves understanding its interaction with the entire system. Ignoring these details can lead to premature failure.

The Energizer Requirement for PTFE Seals

A critical detail for PTFE seals is that they are not inherently elastic. Due to this rigidity, they must be used with an O-ring energizer.

The energizer is a standard O-ring that sits behind the PTFE seal. It provides the constant outward radial force needed to press the seal against the cylinder bore, ensuring a proper seal, especially at low pressures.

Material Compatibility is Non-Negotiable

The seal material must be chemically compatible with the system fluid. A seal made from a material that degrades when exposed to a specific hydraulic oil or synthetic lubricant will quickly fail, leading to system downtime.

Temperature, Pressure, and Wear Life

Every seal has an operating range for temperature and pressure. Exceeding these limits will cause material failure. Likewise, using a high-friction seal in a high-speed application will cause rapid wear, shortening the component's lifespan and contaminating the system.

Making the Right Choice for Your Goal

The immense list of industries using piston seals—from mining and marine to pharmaceuticals and aerospace—is simply a reflection of how widespread hydraulic and pneumatic power is. The choice of seal always comes down to the specific system's goal.

- If your primary focus is heavy-duty industrial power: You will be working with hydraulic cylinders, requiring seals designed for high pressure, high stress, and compatibility with hydraulic fluids.

- If your primary focus is high-speed automation or precision: You are likely dealing with pneumatic cylinders, where low-friction seals are essential for efficient and responsive operation.

- If your primary focus is durability in harsh conditions: You should investigate specialized materials like PTFE, but remember they have unique requirements, such as the need for an O-ring energizer.

Ultimately, selecting the correct piston seal is about precisely matching the material and design to the specific pressures, fluids, and motion demands of your system.

Summary Table:

| Application | System Type | Key Seal Requirements |

|---|---|---|

| Heavy-Duty Industrial (e.g., Construction, Presses) | Hydraulic | High pressure, high stress, fluid compatibility |

| High-Speed Automation, Precision Machinery | Pneumatic | Low friction, efficiency, clean operation |

| Harsh Environments (e.g., Aerospace, Marine) | Hydraulic/Pneumatic | Durability, specialized materials like PTFE (requires O-ring energizer) |

Need a high-performance piston seal for your specific application?

At KINTEK, we specialize in manufacturing precision PTFE components, including seals, liners, and labware, for the most demanding industries. Whether you're in semiconductor manufacturing, medical devices, or heavy industrial machinery, we understand the critical balance of pressure, friction, and material compatibility.

We offer custom fabrication from prototypes to high-volume orders, ensuring your seals are perfectly matched to your system's hydraulic fluids, operating temperatures, and motion requirements.

Contact our experts today to discuss your piston seal needs and ensure reliable, efficient performance for your equipment.

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- Why is filled-PTFE often chosen for rotary shaft seal lips? For Unmatched Performance in Extreme Conditions

- Are Teflon encapsulated O-rings compliant with FDA and USP standards? Ensuring Sealing Integrity for Regulated Industries

- What role does the PTFE lining play in these valves? Achieve Superior Chemical Resistance and Purity

- What are the preparation steps before using PTFE heat press sheets? Ensure Flawless Transfers Every Time

- How does the spring energizer work in PTFE seals? Ensure Leak-Free Performance in Extreme Conditions

- Why are PTFE lined valves non-reactive with aggressive chemicals? The Molecular Shield Explained

- What are the chemical resistance properties of PTFE? Unmatched Inertness for Demanding Applications

- What are the main disadvantages of virgin PTFE products in fluid sealing applications? Overcoming Creep and Cold Flow