Preparing a PTFE heat press sheet is a straightforward but critical two-part process. It requires cleansing your heat press to remove any old residue and thoroughly inspecting the sheet itself to ensure it is free from wrinkles, folds, or contaminants that could ruin your transfer.

The goal of preparation is to preserve the pristine, non-stick surface of the PTFE sheet. This simple step is the most important variable you can control to guarantee a flawless transfer, protect your garment, and extend the life of your equipment.

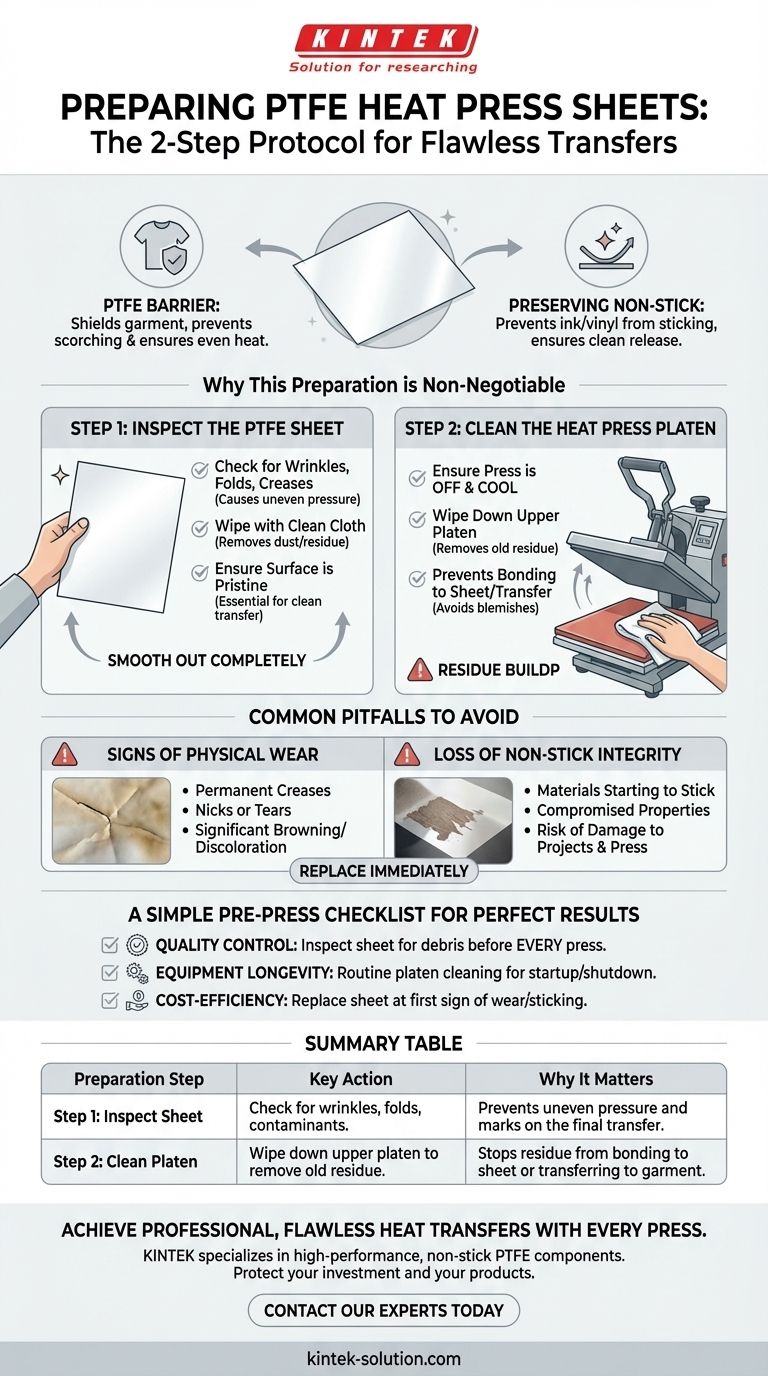

Why This Preparation is Non-Negotiable

To understand the importance of preparation, you must first understand the function of the PTFE sheet. It serves as a vital protective barrier with unique properties.

The Role of the PTFE Barrier

A PTFE sheet shields your garment from direct contact with the hot upper platen of your press. This prevents scorching and ensures even heat distribution.

Simultaneously, its non-stick surface prevents inks, adhesives, and vinyl from sticking to your heat platen, which would otherwise cause a mess and damage your equipment.

Preserving the Non-Stick Surface

The core value of a PTFE sheet is its non-stick property, which allows for clean release and reusability. Any contaminant—dust, old ink, or oils—compromises this surface.

A contaminated sheet can permanently transfer imperfections onto your next project, turning a valuable garment into waste.

The Two-Step Preparation Protocol

For consistent, professional results, integrate these two steps into your workflow before every single pressing session.

Step 1: Inspect the PTFE Sheet

Before placing the sheet, give it a careful visual and physical inspection. Look for any wrinkles, folds, or hard creases.

These imperfections can translate into uneven pressure, leaving faint lines or marks on your final transfer. Smooth the sheet out completely.

Wipe the sheet with a clean, dry cloth to remove any dust or loose residue from previous jobs. A clean surface is essential for a clean transfer.

Step 2: Clean the Heat Press Platen

Ensure your heat press is turned off and cool before cleaning.

Thoroughly wipe down the upper platen to remove any residue from past projects. Even small flecks of ink or adhesive can create problems.

Residue on the platen can heat up and potentially bond to your PTFE sheet or, in some cases, transfer through it, creating a blemish on your project.

Common Pitfalls to Avoid

While PTFE sheets are durable and reusable, they are not permanent. Recognizing when a sheet has reached the end of its useful life is key to avoiding failed presses.

Signs of Physical Wear

A sheet with permanent creases that won't smooth out, nicks, or tears should be discarded immediately. These physical defects will create inconsistent pressure and ruin your work.

Significant browning or discoloration is another sign that the material is beginning to degrade from repeated heat cycles and should be replaced.

Loss of Non-Stick Integrity

If you notice materials starting to stick to the sheet, its non-stick properties have been compromised. Continuing to use it risks damaging both your projects and your heat press.

At this point, the sheet is no longer a protective tool but a liability. Its low replacement cost is a minor investment compared to the cost of a ruined garment.

A Simple Pre-Press Checklist for Perfect Results

Integrate this thinking into your routine to ensure every press is a success.

- If your primary focus is quality control: Always inspect the sheet for any specks of debris or old residue before every single press.

- If your primary focus is equipment longevity: Make cleaning your upper platen a routine part of your startup and shutdown process to prevent residue buildup.

- If your primary focus is cost-efficiency: Replace your sheet at the first sign of permanent creasing or sticking to avoid wasting expensive garments on a failed transfer.

This simple habit of preparation is the foundation of consistent, professional-grade results.

Summary Table:

| Preparation Step | Key Action | Why It Matters |

|---|---|---|

| Step 1: Inspect Sheet | Check for wrinkles, folds, and contaminants. | Prevents uneven pressure and marks on the final transfer. |

| Step 2: Clean Platen | Wipe down the upper platen to remove old residue. | Stops residue from bonding to the sheet or transferring to the garment. |

Achieve professional, flawless heat transfers with every press. The right PTFE sheet is your most critical tool for quality control and equipment protection. KINTEK specializes in manufacturing high-performance, non-stick PTFE components—including durable heat press sheets—for industrial and specialized applications. We prioritize precision and offer custom fabrication from prototypes to high-volume orders. Protect your investment and your products—contact our experts today to find the perfect PTFE solution for your needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How are PTFE lip seals utilized in automotive applications? A Guide to Extreme Performance Sealing

- What materials can PTFE O-rings be produced with? From Virgin PTFE to Enhanced Compounds

- What are the different spring load ratings for PTFE seals? Optimize Performance & Lifespan

- What are some specific uses of PTFE in chemical handling? Enhance Safety and Reliability in Your Process

- What are the longevity and durability benefits of PTFE gaskets? Achieve Reliable, Long-Lasting Sealing Performance

- What are the typical applications of PTFE lined ball valves? Essential for Corrosive & High-Purity Systems

- What precautions should be taken for maximum seal life expectancy? Follow the 75% Rule for Longevity

- What are the temperature limitations of Teflon packing? Ensure Sealing Integrity from -200°C to 260°C