The fundamental reason PTFE-lined valves are non-reactive is the extraordinary strength and stability of PTFE's molecular structure. At its core is a chain of carbon atoms completely shielded by a tight sheath of fluorine atoms, creating the strongest single bond in organic chemistry and making the molecule almost entirely inert.

The chemical inertness of Polytetrafluoroethylene (PTFE) is not a surface-level feature; it is a direct consequence of its unique molecular architecture. The powerful Carbon-Fluorine bonds create a non-porous, low-energy surface that repels virtually all aggressive chemicals.

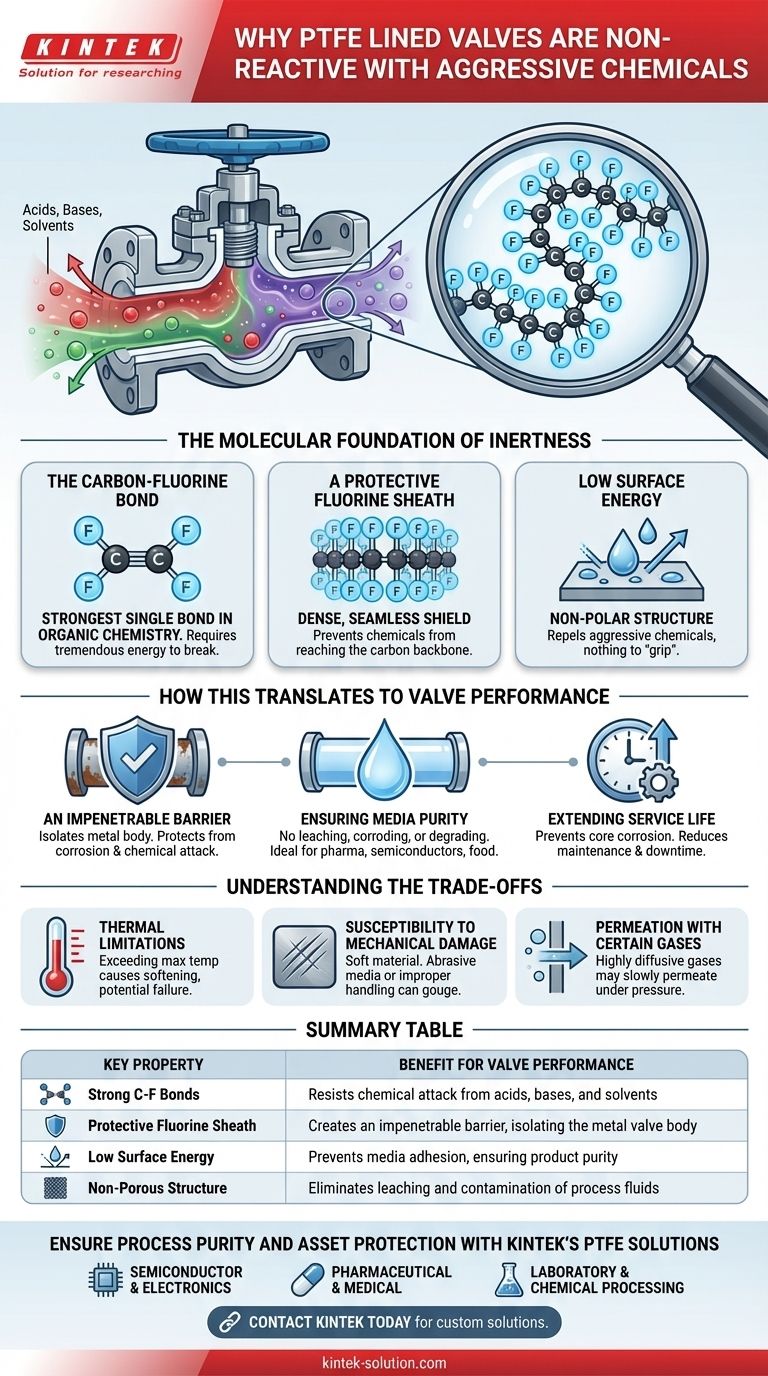

The Molecular Foundation of Chemical Inertness

To understand why PTFE works so well, we must look at its structure. It's a simple polymer, but its design is what grants it exceptional properties.

The Carbon-Fluorine Bond

The bond between carbon and fluorine atoms is the strongest single bond known in organic chemistry. This immense strength means it takes a tremendous amount of energy to break it, making the molecule highly resistant to chemical attack.

A Protective Fluorine Sheath

In the PTFE molecule, the larger fluorine atoms wrap tightly around the central carbon backbone. This creates a dense, uniform, and seamless shield that physically prevents chemicals from ever reaching the more vulnerable carbon chain.

Low Surface Energy

This stable, non-polar molecular structure results in a very low surface energy. This is why PTFE is famous for its non-stick properties; chemicals have nothing to "grip" onto, making it difficult for them to initiate a reaction.

How This Translates to Valve Performance

This molecular stability is not just a scientific curiosity. It delivers tangible, critical benefits when PTFE is used as a valve lining.

An Impenetrable Barrier

The PTFE lining acts as a complete shield, isolating the metal valve body from the process media. This protects the structural components from corrosion, chemical attack, and degradation from strong acids, bases, and solvents.

Ensuring Media Purity

Because PTFE is so non-reactive, it does not leach, corrode, or degrade. No particles or contaminants from the valve lining enter the process fluid, which is an absolute requirement in industries like pharmaceuticals, semiconductors, and food and beverage.

Extending Service Life

By preventing corrosion of the core valve components, a PTFE lining dramatically increases the valve's operational lifespan. This reduces maintenance costs, minimizes downtime, and improves overall plant safety and reliability.

Understanding the Trade-offs

While its chemical resistance is nearly universal, PTFE is not without its limitations. A true expert understands the context in which it operates best.

Thermal Limitations

PTFE has a defined operating temperature range. Exceeding its maximum service temperature can cause the material to soften, deform, and potentially fail, compromising the protective barrier.

Susceptibility to Mechanical Damage

Compared to metal, PTFE is a relatively soft material. Abrasive slurries, high-velocity particles, or improper handling can scratch or gouge the lining, creating a pathway for corrosive media to attack the valve body.

Permeation with Certain Gases

While excellent against liquids, highly diffusive gases (like chlorine or hydrogen) can, over time and under certain pressures, slowly permeate the PTFE liner. This must be considered in very specific, high-purity gas applications.

Making the Right Choice for Your Application

Selecting the right material requires aligning its properties with your primary objective.

- If your primary focus is product purity: PTFE is an industry standard because its inert nature prevents any contamination of the media.

- If your primary focus is corrosion resistance for aggressive chemicals: The stable molecular shield of PTFE provides reliable, long-term protection for valve assets against a vast range of acids, bases, and solvents.

- If your application involves high-velocity or abrasive media: You must verify that a standard PTFE lining is suitable, as mechanical wear can be a limiting factor.

Ultimately, leveraging PTFE's molecular stability is the key to ensuring both the integrity of your process and the longevity of your equipment.

Summary Table:

| Key Property | Benefit for Valve Performance |

|---|---|

| Strong C-F Bonds | Resists chemical attack from acids, bases, and solvents |

| Protective Fluorine Sheath | Creates an impenetrable barrier, isolating the metal valve body |

| Low Surface Energy | Prevents media adhesion, ensuring product purity |

| Non-Porous Structure | Eliminates leaching and contamination of process fluids |

Ensure Process Purity and Asset Protection with KINTEK's PTFE Solutions

Leverage the unparalleled chemical resistance of PTFE for your most demanding applications. KINTEK specializes in manufacturing high-precision PTFE components, including custom-lined valves, seals, and labware.

We serve industries where contamination and corrosion are not an option:

- Semiconductor & Electronics: For ultra-pure chemical handling.

- Pharmaceutical & Medical: To meet strict purity standards.

- Laboratory & Chemical Processing: For reliable performance with aggressive media.

Our expertise spans from rapid prototyping to high-volume production, ensuring you get a solution tailored to your specific operational needs and chemical compatibility requirements.

Contact KINTEK today to discuss your application and receive a custom solution that protects your process and extends equipment life.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the advantages of Teflon encapsulated O-rings? Superior Sealing for Extreme Conditions

- What are the general advantages of using Teflon coating in industrial applications? Boost Efficiency & Protect Equipment

- What happens when lubricants interfere with PTFE liner function? Avoid Accelerated Wear and System Failure

- What are the key properties of Teflon sheets? A Guide to PTFE's Versatility

- What chemical resistance properties does PTFE offer? Master Its Inertness for Demanding Applications

- What post-machining steps improve PTFE surface finish? Achieve a Smooth, High-Performance Surface

- What types of Teflon backup rings are available and their uses? Ensure Sealing Integrity in High-Pressure Systems

- Why is PTFE considered an ideal material for demanding hydraulic and pneumatic applications? Ensure Superior Sealing Performance and Reliability