In short, filled-PTFE is chosen for rotary shaft seal lips because of its unparalleled ability to perform reliably in extreme operating conditions. Its unique combination of extremely low friction, broad temperature stability, and near-universal chemical resistance allows it to succeed in high-speed, high-pressure, and aggressive environments where traditional elastomeric seals would rapidly fail.

The decision to use a filled-PTFE seal is fundamentally a choice for operational resilience. While standard seals handle typical conditions, filled-PTFE is the engineered solution for demanding applications where high speeds, extreme temperatures, aggressive chemicals, or a lack of lubrication are non-negotiable factors.

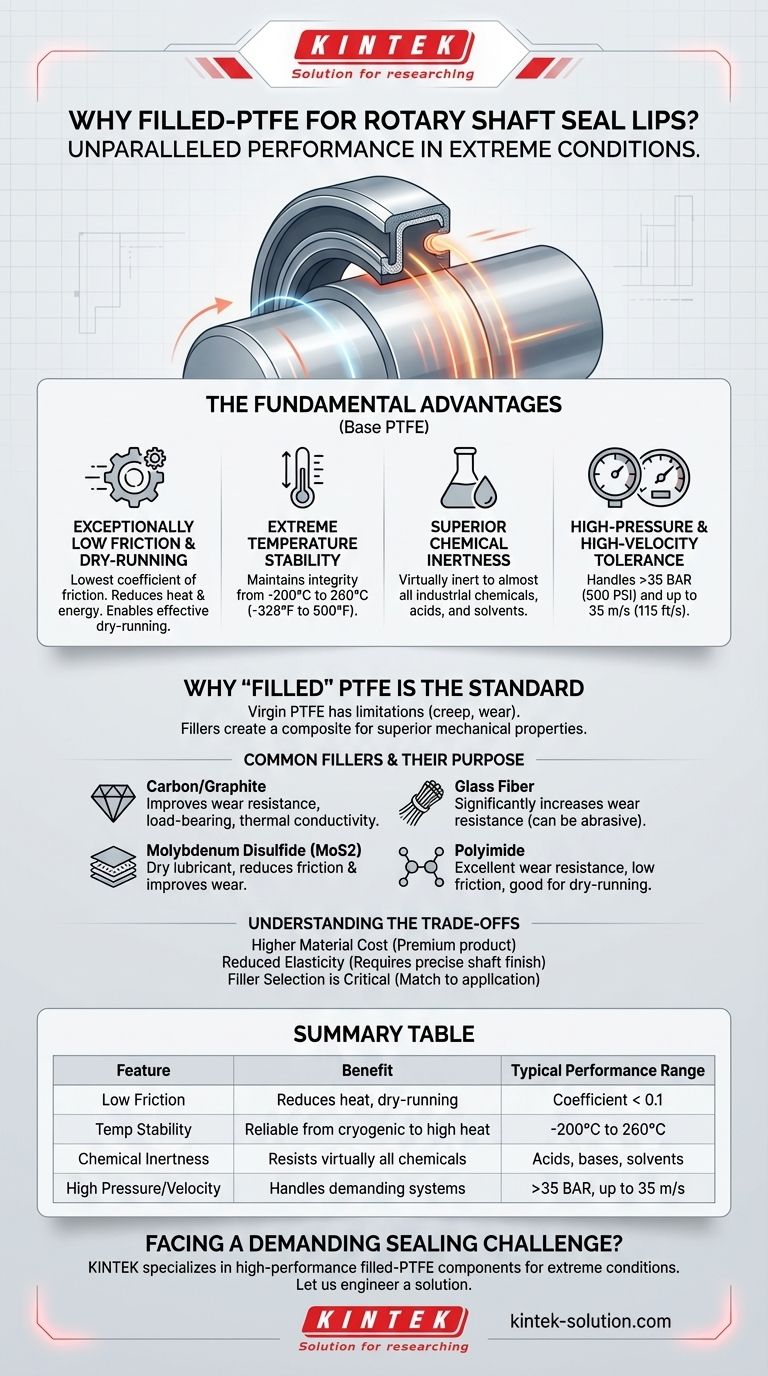

The Fundamental Advantages of a PTFE Sealing Lip

Before discussing fillers, it's crucial to understand the core properties of the base material, Polytetrafluoroethylene (PTFE), that make it so suitable for demanding sealing applications.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This allows it to glide smoothly over rotating shafts, significantly reducing heat generation and energy consumption.

This property also enables dry-running capabilities, meaning the seal can function effectively for periods without lubrication, a scenario that would quickly destroy most other seal materials.

Extreme Temperature Stability

PTFE seals maintain their integrity across an exceptionally wide temperature range, typically from -200°C to 260°C (-328°F to 500°F).

This stability prevents the material from becoming brittle at cryogenic temperatures or degrading in high-heat applications, ensuring a consistent seal.

Superior Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals, including aggressive acids, bases, solvents, and oils.

This resistance ensures the seal lip will not swell, soften, or degrade when exposed to corrosive media, guaranteeing long-term reliability and preventing contamination.

High-Pressure and High-Velocity Tolerance

Compared to standard elastomeric seals, PTFE can withstand significantly higher operational limits.

It can handle pressures exceeding 35 BAR (500 PSI) and surface velocities of up to 35 m/s (115 ft/s), making it the default choice for high-performance hydraulic and pneumatic systems.

Why "Filled" PTFE is the Standard

While virgin PTFE has excellent properties, it has inherent weaknesses, such as a tendency to deform under load (creep) and relatively low wear resistance. Fillers are added to counteract these limitations and tailor the seal's performance to specific applications.

Enhancing Performance with Fillers

Fillers are not merely additives; they are functional components that are compounded with the base PTFE to create a new composite material with superior mechanical properties.

The addition of these fillers dramatically improves wear resistance, thermal conductivity (to better dissipate heat from the sealing point), and dimensional stability under load.

Common Fillers and Their Purpose

The choice of filler is critical and depends entirely on the application's demands for pressure, temperature, speed, and media.

Common fillers include:

- Carbon/Graphite: Improves wear resistance, load-bearing capacity, and thermal conductivity.

- Glass Fiber: Significantly increases wear resistance, though it can be abrasive to softer shaft materials.

- Molybdenum Disulfide (MoS2): Acts as a dry lubricant, further reducing friction and improving wear characteristics.

- Polyimide: Offers excellent wear resistance and low friction properties, especially in dry-running applications.

Understanding the Trade-offs

While highly effective, filled-PTFE is not a universal solution. An objective evaluation requires acknowledging its limitations.

Higher Material Cost

Filled-PTFE seals are a premium product. They are generally more expensive upfront than their standard nitrile or viton elastomeric counterparts. This cost is justified by the enhanced performance and reduced maintenance in demanding environments.

Reduced Elasticity

PTFE is a much more rigid material than rubber. It lacks the elastic memory of elastomers, meaning it will not rebound as effectively if deformed.

This requires more precise shaft surface finishes and careful installation procedures to prevent leaks. Any nicks or scratches on the shaft are more likely to create a leak path.

Filler Selection is Critical

The benefits of a filled-PTFE seal are entirely dependent on choosing the correct filler for the job. Using a seal with a glass fiber filler on a soft aluminum shaft, for example, could lead to premature shaft wear and subsequent failure.

Making the Right Choice for Your Application

Selecting the appropriate seal material comes down to a clear understanding of the operational environment and performance goals.

- If your primary focus is high speed and/or dry running: PTFE's intrinsically low friction is its most critical advantage, preventing overheating and catastrophic failure where other materials could not survive.

- If your primary focus is aggressive chemical exposure: PTFE's chemical inertness ensures the seal will not degrade, providing the longest possible service life and preventing system contamination.

- If your primary focus is extreme temperatures (hot or cold): PTFE provides a stable sealing solution where common elastomers would become brittle or break down.

- If your primary focus is a cost-sensitive, standard-duty application: A traditional elastomeric seal is likely the more appropriate and economical choice, as the advanced capabilities of PTFE would be unnecessary.

Ultimately, choosing filled-PTFE is an engineering decision to ensure operational reliability when conditions push beyond the limits of conventional materials.

Summary Table:

| Feature | Benefit | Typical Performance Range |

|---|---|---|

| Low Friction | Reduces heat, enables dry-running | Coefficient of friction < 0.1 |

| Temperature Stability | Reliable performance from cryogenic to high heat | -200°C to 260°C (-328°F to 500°F) |

| Chemical Inertness | Resists virtually all industrial chemicals | Compatible with acids, bases, solvents |

| High Pressure/Velocity | Handles demanding hydraulic/pneumatic systems | >35 BAR (500 PSI), up to 35 m/s (115 ft/s) |

Facing a demanding sealing challenge that standard seals can't handle?

At KINTEK, we specialize in manufacturing high-performance filled-PTFE components, including custom rotary shaft seals, for the most challenging applications in the semiconductor, medical, laboratory, and industrial sectors. Our expertise in precision production and custom fabrication—from prototypes to high-volume orders—ensures you get a seal engineered for resilience and reliability in your specific environment.

Let us engineer a solution for your extreme conditions. Contact our experts today to discuss your application requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance