At its core, the spring energizer in a PTFE seal works by providing a constant mechanical force. This spring pushes the PTFE seal lips outward, creating a tight, reliable seal against the mating surfaces. It solves PTFE's inherent lack of elasticity, ensuring the seal remains engaged even when system pressure is low or non-existent.

The fundamental challenge with PTFE is its exceptional low-friction and chemical-resistant properties are offset by its poor material memory. The spring energizer acts as the seal's permanent memory, delivering the consistent force needed to maintain a seal across wide temperature ranges, pressure fluctuations, and the entire life of the component.

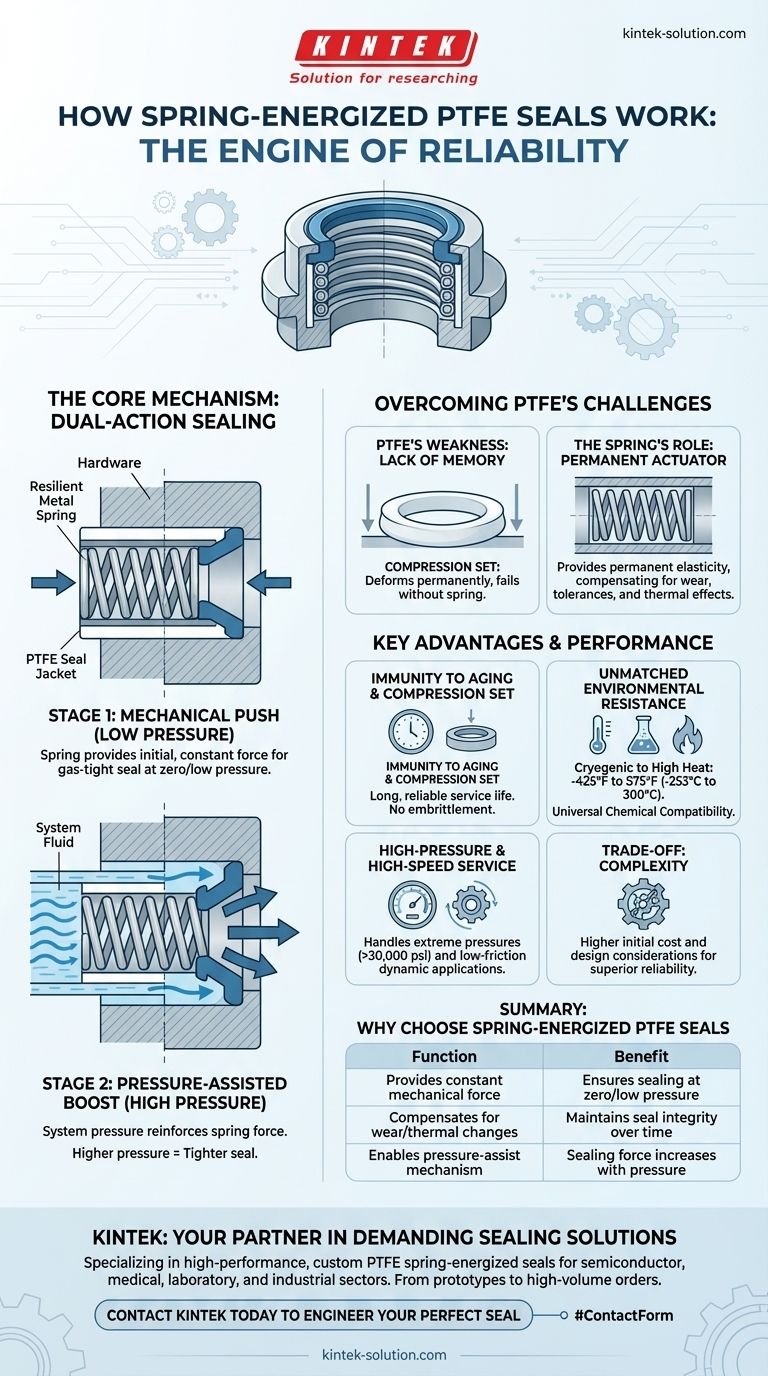

The Dual-Action Sealing Mechanism

A spring-energized seal leverages two distinct forces to ensure leak-free performance: the initial mechanical force from the spring and the subsequent force applied by system pressure.

Stage 1: The Mechanical Push at Low Pressure

When the seal is installed in its housing, or "gland," it is compressed. The resilient metal spring inside the PTFE jacket responds with a constant outward force.

This spring action pushes the seal lips firmly against the hardware, creating the initial, gas-tight seal. This is critical for sealing at zero or very low system pressures where there isn't enough fluid force to actuate the seal on its own.

Stage 2: The Pressure-Assisted Boost

As system pressure increases, that pressure finds its way into the groove of the seal profile.

This pressure acts upon the seal's inner surfaces, powerfully reinforcing the spring's initial push. This dynamic relationship means the higher the system pressure, the tighter the seal becomes, dramatically enhancing its sealing force beyond the initial load.

Why PTFE Requires an Energizer

While an exceptional material, PTFE on its own makes for a poor seal in many dynamic or demanding applications. The spring is not an accessory; it is an essential component that unlocks PTFE's true potential.

Overcoming a Lack of "Memory"

Elastomeric seals, like rubber O-rings, possess natural resilience or "memory." When compressed, they want to return to their original shape. PTFE does not share this characteristic.

Once deformed under load, PTFE tends to stay that way. This phenomenon, known as compression set, is a primary reason un-energized plastic seals fail.

The Spring as a Permanent Actuator

The energizer effectively gives the seal permanent elasticity. It continuously compensates for factors that would otherwise cause a leak.

This includes minor wear on the seal lips over time, variations in gland manufacturing tolerances, and thermal expansion or contraction of the sealing components.

Key Advantages and Trade-offs

The combination of a PTFE jacket and a metal spring creates a sealing solution with a unique performance profile, making it the superior choice in applications where other seals consistently fail.

Immunity to Aging and Compression Set

Unlike rubber, the spring and PTFE jacket are immune to aging, embrittlement, and compression set. This results in a significantly longer and more reliable service life, especially in harsh chemical or thermal environments.

Unmatched Environmental Resistance

The design allows for service in extreme conditions, from cryogenic temperatures (-425°F / -253°C) to high heat (575°F / 300°C). Combined with PTFE's near-universal chemical compatibility, these seals can operate where elastomers would rapidly degrade.

High-Pressure and High-Speed Service

The pressure-assist mechanism allows these seals to handle extreme pressures (over 30,000 psi) without extruding. The low-friction nature of PTFE also makes them ideal for high-speed dynamic applications where friction and heat generation are major concerns.

The Trade-off: Design Complexity

The primary trade-off is higher initial cost and greater design consideration compared to a simple O-ring. The performance gains, however, often justify the investment in applications where reliability is paramount.

Making the Right Choice for Your Application

Specify a spring-energized PTFE seal when standard elastomeric or polymer seals cannot meet the operational demands of the environment.

- If your primary focus is extreme temperature service: This design maintains its sealing force in both cryogenic and high-heat conditions where elastomers become brittle or degrade.

- If your primary focus is chemical compatibility: The PTFE jacket offers a nearly universal solution for sealing aggressive chemicals, solvents, and corrosive media.

- If your primary focus is high-pressure reliability: The pressure-assisted design ensures the seal becomes tighter as pressure increases, preventing leaks and extrusion.

- If your primary focus is low-friction dynamic sealing: The inherent properties of PTFE provide smooth, low-drag performance without the need for lubrication, eliminating stick-slip issues.

Ultimately, this design transforms a superior but inelastic material into a highly reliable and dynamic sealing solution for the most demanding environments.

Summary Table:

| Function | Benefit |

|---|---|

| Provides constant mechanical force | Ensures sealing at zero/low pressure |

| Compensates for wear and thermal changes | Maintains seal integrity over time |

| Enables pressure-assist mechanism | Sealing force increases with system pressure |

| Unlocks PTFE's chemical/thermal resistance | Operates in extreme environments where elastomers fail |

Need a reliable sealing solution for your most demanding applications?

At KINTEK, we specialize in manufacturing high-performance, custom PTFE components, including spring-energized seals. Our precision production ensures your seals deliver leak-free performance in extreme conditions—from high-pressure systems and aggressive chemicals to cryogenic temperatures and high-speed dynamic applications.

We partner with the semiconductor, medical, laboratory, and industrial sectors to provide custom fabrication from prototypes to high-volume orders.

Contact KINTEK today to discuss your specific requirements and let our experts help you engineer the perfect seal for your critical application.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What makes PTFE-lined diaphragm valves suitable for wastewater treatment? Ensure Reliability and Cost Savings

- What are the durability benefits of PTFE washers? Achieve Unmatched Chemical & Thermal Resistance

- What are the primary applications of PTFE expansion bellows? Protect Piping Systems from Stress & Corrosion

- What are some common structural types of PTFE gaskets? Choose the Right Seal for Your Application

- What are some modern applications of PTFE due to its electrical insulative properties? | High-Frequency & Extreme Environment Solutions

- What are some household applications of Teflon in furniture? Protect Floors & Upholstery with Ease

- What advancements are being made in recycling Teflon scrap? From Micronization to Upcycling

- What temperature range can PTFE balls withstand, and why is this beneficial? Unlock Extreme Thermal Performance