The lifespan of PTFE tubing and rods is not a fixed value but is governed by the specific demands of its operating environment. While known for its exceptional durability, its longevity is primarily dictated by four key factors: thermal stress, chemical exposure, mechanical load, and environmental radiation. Under ideal, low-stress conditions, PTFE components can last for many years, but any one of these factors can significantly accelerate degradation.

While PTFE is famous for its chemical and thermal resistance, its functional lifespan is most often determined by its physical limitations. Mechanical stress—specifically pressure, abrasion, and a phenomenon known as "creep"—is the most common and frequently overlooked cause of premature failure in real-world applications.

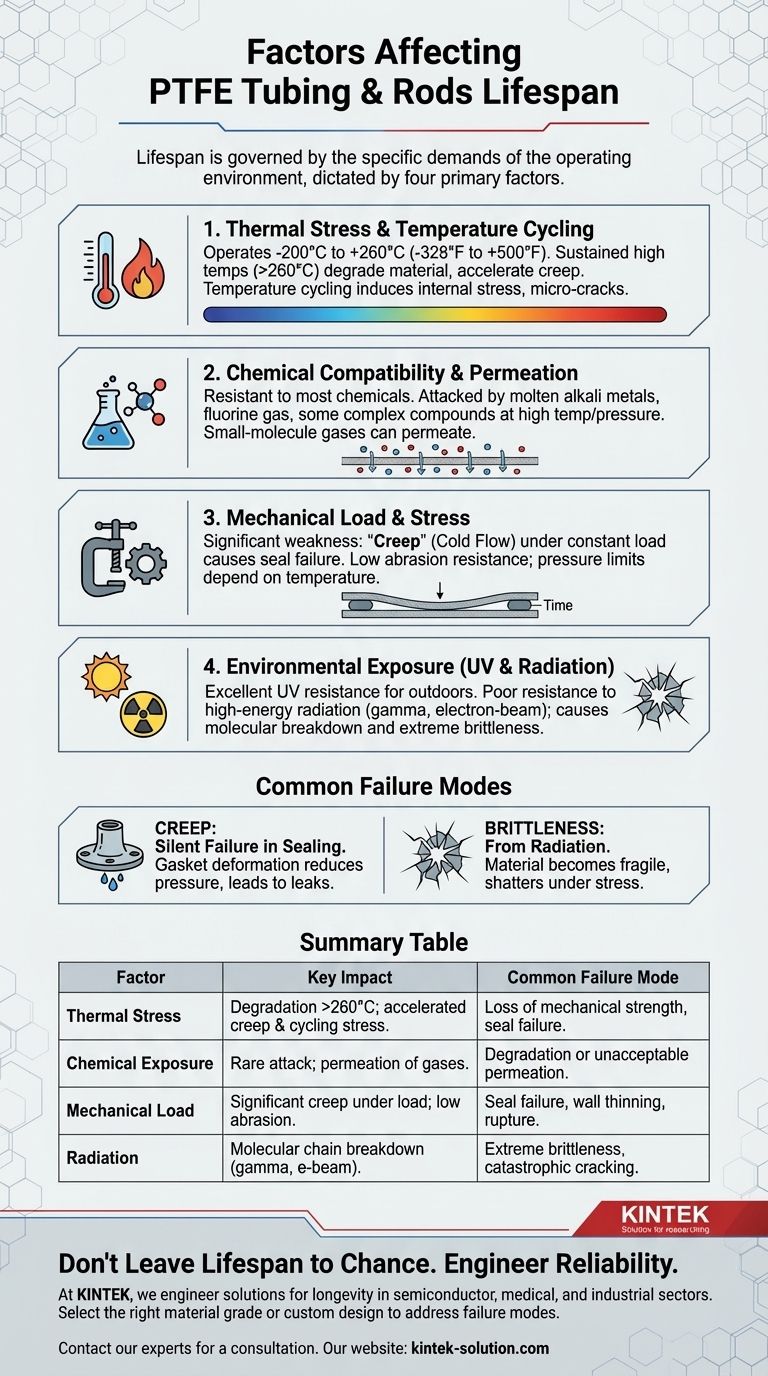

The Four Primary Factors Governing PTFE Lifespan

To accurately predict the service life of a PTFE component, you must evaluate the combined impact of its working conditions. A factor that is benign in isolation can become a critical point of failure when combined with another.

Factor 1: Thermal Stress and Temperature Cycling

Polytetrafluoroethylene (PTFE) has an impressively wide service temperature range, typically from -200°C to +260°C (-328°F to +500°F). However, performance degrades significantly near these boundaries.

Sustained operation above 260°C will cause the material to degrade, releasing potentially hazardous fumes. More commonly, high temperatures dramatically reduce PTFE's mechanical strength and accelerate creep.

Even within its safe operating range, temperature cycling (repeated heating and cooling) can induce thermal expansion and contraction. This process creates internal stresses that can lead to micro-cracks and eventual failure, especially in tight-tolerance seals.

Factor 2: Chemical Compatibility and Permeation

PTFE is famously inert and resistant to nearly all industrial chemicals, acids, and bases. This is one of its most valuable properties.

However, a few substances can attack it. These are primarily molten alkali metals (like sodium), elemental fluorine gas, and certain rare, complex halogenated compounds at high temperatures and pressures.

It is also important to distinguish between degradation and permeation. While a chemical may not damage the PTFE structure, some gases and liquids can slowly diffuse through it. In high-pressure gas or vacuum applications, this permeation can be a limiting factor over time.

Factor 3: Mechanical Load and Stress

This is often the most critical and misunderstood area of PTFE failure. Despite its strengths, PTFE is a relatively soft material.

Creep (or "Cold Flow") is PTFE's most significant mechanical weakness. When subjected to a constant compressive load (like a gasket under bolt pressure), the material will slowly deform and "flow" away from the pressure point over time, eventually causing the seal to fail.

Pressure and Abrasion also limit lifespan. The maximum pressure a PTFE tube can handle is highly dependent on temperature; a tube rated for 1,000 psi at room temperature may only be suitable for a fraction of that at 200°C. Likewise, its surface is easily scratched and worn away by abrasive slurries or dynamic sliding contact.

Factor 4: Environmental Exposure (UV and Radiation)

PTFE has excellent resistance to ultraviolet (UV) radiation from sunlight, making it suitable for outdoor applications without risk of degradation from this source.

Conversely, it has very poor resistance to high-energy radiation, such as gamma or electron-beam radiation. This type of exposure breaks down the polymer's molecular chains, causing a dramatic loss of strength and making the material extremely brittle.

Understanding the Trade-offs and Failure Modes

Simply knowing the factors isn't enough. Understanding how they lead to failure is key to proper material selection and design.

Creep: The Silent Failure

Creep is the primary failure mode in static sealing applications. A PTFE gasket or O-ring may function perfectly upon installation, but over weeks or months, the constant compressive force will cause it to deform, reducing sealing pressure and leading to leaks. This effect is significantly worsened at higher temperatures.

Brittleness from Radiation

In environments with ionizing radiation, PTFE will lose its signature flexibility. A component that was once tough and pliable can become as fragile as glass, cracking or shattering under minimal vibration or mechanical stress. This is a catastrophic failure mode.

Permeation vs. Degradation

It is crucial to understand that a lack of chemical attack does not guarantee containment. In applications transferring small-molecule gases like helium or hydrogen at high pressure, the gas can slowly pass directly through the PTFE wall, even with no damage to the material itself. This can be unacceptable in sensitive systems.

Making the Right Choice for Your Application

To ensure reliable performance, evaluate your application against these specific failure modes.

- If your primary focus is high-temperature sealing: Pay close attention to the combined effects of temperature and compressive load, as this is the primary driver for material creep.

- If your primary focus is chemical transport: Verify that your media is not one of the few aggressive exceptions and carefully consider permeation rates for high-purity or high-pressure gas systems.

- If your primary focus is dynamic or structural use: Account for PTFE's softness and low abrasion resistance; consider filled PTFE grades (e.g., glass or carbon-filled) for improved mechanical strength and creep resistance.

- If your primary focus is use in a radiation environment: Avoid standard PTFE entirely and explore alternative polymers like PEEK or specific polyimides designed for radiation resistance.

By understanding these factors, you can move from hoping for longevity to engineering it directly into your design.

Summary Table:

| Factor | Key Impact on PTFE Lifespan | Common Failure Mode |

|---|---|---|

| Thermal Stress | Degradation above 260°C; accelerated creep and micro-cracking from temperature cycling. | Loss of mechanical strength, seal failure. |

| Chemical Exposure | Rare attack from specific chemicals (e.g., molten alkali metals); permeation of gases. | Degradation or unacceptable permeation rates. |

| Mechanical Load | Significant creep (cold flow) under constant load; low abrasion resistance. | Seal failure, wall thinning, rupture. |

| Radiation | Molecular chain breakdown from gamma or e-beam radiation. | Extreme brittleness, catastrophic cracking. |

Don't leave your PTFE component's lifespan to chance.

At KINTEK, we don't just manufacture PTFE seals, liners, and labware—we engineer solutions for longevity. By understanding the precise thermal, chemical, mechanical, and environmental demands of your application in the semiconductor, medical, or industrial sectors, we can help you select the right material grade or design a custom component that proactively addresses these failure modes.

Let us help you engineer reliability directly into your design, from prototype to high-volume production.

Contact our experts today for a consultation on your specific application requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability