In practice, the official service temperature for Polytetrafluoroethylene (PTFE) is exceptionally wide, ranging from -200°C to +260°C (-328°F to +500°F). However, the critical factor for machining is not this static range, but rather the material's poor heat dissipation. The heat generated during cutting can easily cause deformation and ruin dimensional accuracy long before the material itself begins to degrade.

The core challenge when machining PTFE is not its high-temperature tolerance, but its high rate of thermal expansion combined with low thermal conductivity. This means localized heat from cutting builds up quickly, causing the material to expand and warp, which is the primary source of inaccuracy.

Understanding PTFE's Thermal Behavior

To machine PTFE effectively, you must focus on managing thermal effects rather than worrying about the material's absolute temperature limit. Its unique properties create a specific set of challenges.

The Official Service Temperature Range

PTFE is renowned for its thermal stability. It can operate continuously in high-heat applications up to 260°C (500°F) and remains functional in cryogenic conditions as low as -200°C (-328°F). This makes it a go-to material for extreme environments.

The Critical Challenge: Thermal Expansion

The primary issue during machining is thermal expansion. PTFE expands and contracts significantly more than metals or other engineering plastics when its temperature changes. Because it's also a poor thermal conductor, heat from a cutting tool doesn't spread out; it concentrates in the cutting zone.

This localized heat causes the material to expand rapidly, leading to inaccurate cuts. Once the part cools, it will contract, resulting in a final dimension that is smaller than intended.

The Inevitable Risk of Deformation

Heat softens PTFE, making it highly susceptible to deformation. This is amplified by two factors: the pressure from the cutting tool and the clamping force from your fixtures. A part that is dimensionally stable at room temperature can easily warp or distort when heat is introduced.

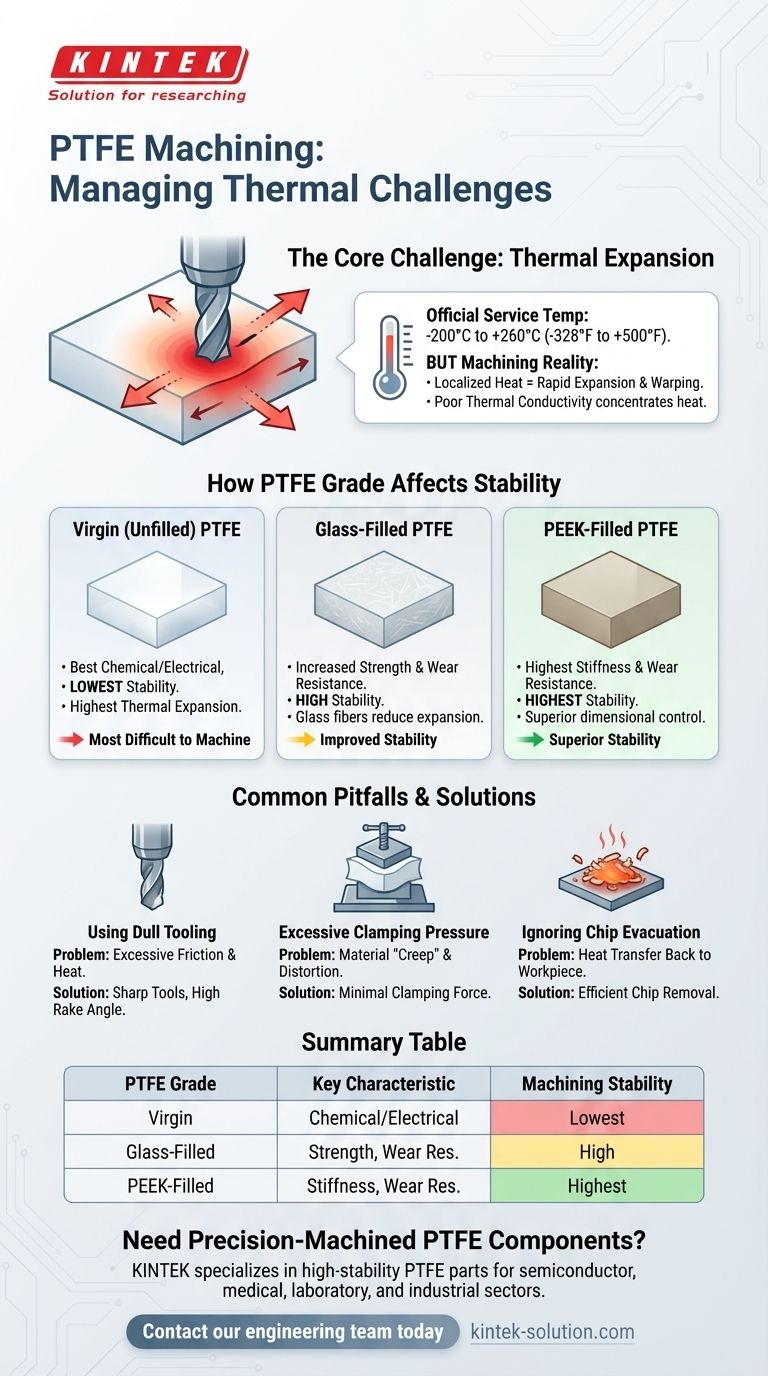

How PTFE Grade Affects Machining Stability

The type of PTFE you are machining has a direct impact on its thermal stability. Additives, known as fillers, are used to counteract the material's inherent weaknesses.

Virgin (Unfilled) PTFE

This is the pure, unmodified grade. While it offers the best chemical resistance and electrical insulation, it has the highest rate of thermal expansion. It is the most difficult grade to machine to tight tolerances due to its dimensional instability.

Filled Grades (Glass, PEEK)

Reinforcing PTFE with fillers like glass fibers or PEEK dramatically improves its properties for machining. These fillers add rigidity and significantly reduce the rate of thermal expansion.

Glass-filled PTFE is much stronger and more resistant to wear and creep. PEEK-filled PTFE offers even higher stiffness and superb wear resistance. Both are far more dimensionally stable under the heat of machining than virgin PTFE.

Common Pitfalls to Avoid

Success with PTFE requires avoiding common mistakes that generate excessive heat and pressure.

Using Dull Tooling

Dull tools don't cut; they plow through the material. This generates a massive amount of friction and heat, which is the root cause of nearly all machining problems with PTFE. Always use extremely sharp tools with a high rake angle.

Applying Excessive Clamping Pressure

PTFE is a soft material that will deform or "creep" even under moderate pressure. Fixtures should provide robust support with minimal clamping force. Over-tightening a vise will distort the raw stock, leading to an inaccurate final part.

Ignoring Chip Evacuation

Because PTFE is a poor heat conductor, the chips carry away a significant amount of thermal energy. Inefficient chip evacuation allows hot chips to sit on the workpiece, transferring heat back into it and compounding expansion problems.

Making the Right Choice for Your Goal

Your machining strategy must align with the material grade and the final requirements of the part.

- If your primary focus is maximum chemical resistance or electrical insulation: Use Virgin PTFE, but use very sharp tooling, high speeds, and low feed rates to minimize heat generation.

- If your primary focus is dimensional accuracy and wear resistance: Strongly consider a filled grade like glass-filled or PEEK-filled PTFE, as they are inherently more stable and forgiving during the machining process.

- If your primary focus is visibility or color-coding: Treat pigmented PTFE similarly to virgin grades, as the pigments do not significantly improve thermal stability.

Ultimately, mastering PTFE machining comes from understanding that you are managing thermal expansion, not just cutting a material.

Summary Table:

| PTFE Grade | Key Characteristic | Machining Stability |

|---|---|---|

| Virgin (Unfilled) | Best chemical/electrical resistance | Lowest; highest thermal expansion |

| Glass-Filled | Increased strength, wear resistance | High; significantly improved stability |

| PEEK-Filled | Highest stiffness, wear resistance | Highest; superior dimensional stability |

Need precision-machined PTFE components that hold their shape under thermal stress?

At KINTEK, we specialize in machining high-stability PTFE parts for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in managing thermal expansion ensures your seals, liners, and labware meet exact specifications, from prototypes to high-volume orders.

Contact our engineering team today to discuss your project requirements and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What temperature can PTFE sheets withstand? From -200°C to +260°C with Unmatched Stability

- What factors contribute to the durability of PTFE O-rings? Maximize Seal Life in Harsh Environments

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What is the development history of PTFE O-ring seals? From Simple Shapes to High-Performance Seals

- What standards do PTFE encapsulated O-rings meet for compression set? Ensure Long-Term Seal Reliability

- In what scenario might the higher claimed PTFE temperature limits be acceptable? Handling Brief Thermal Spikes Safely

- What are the key properties of PTFE rotary shaft seals? Solve Extreme Chemical, Temperature, and Speed Challenges