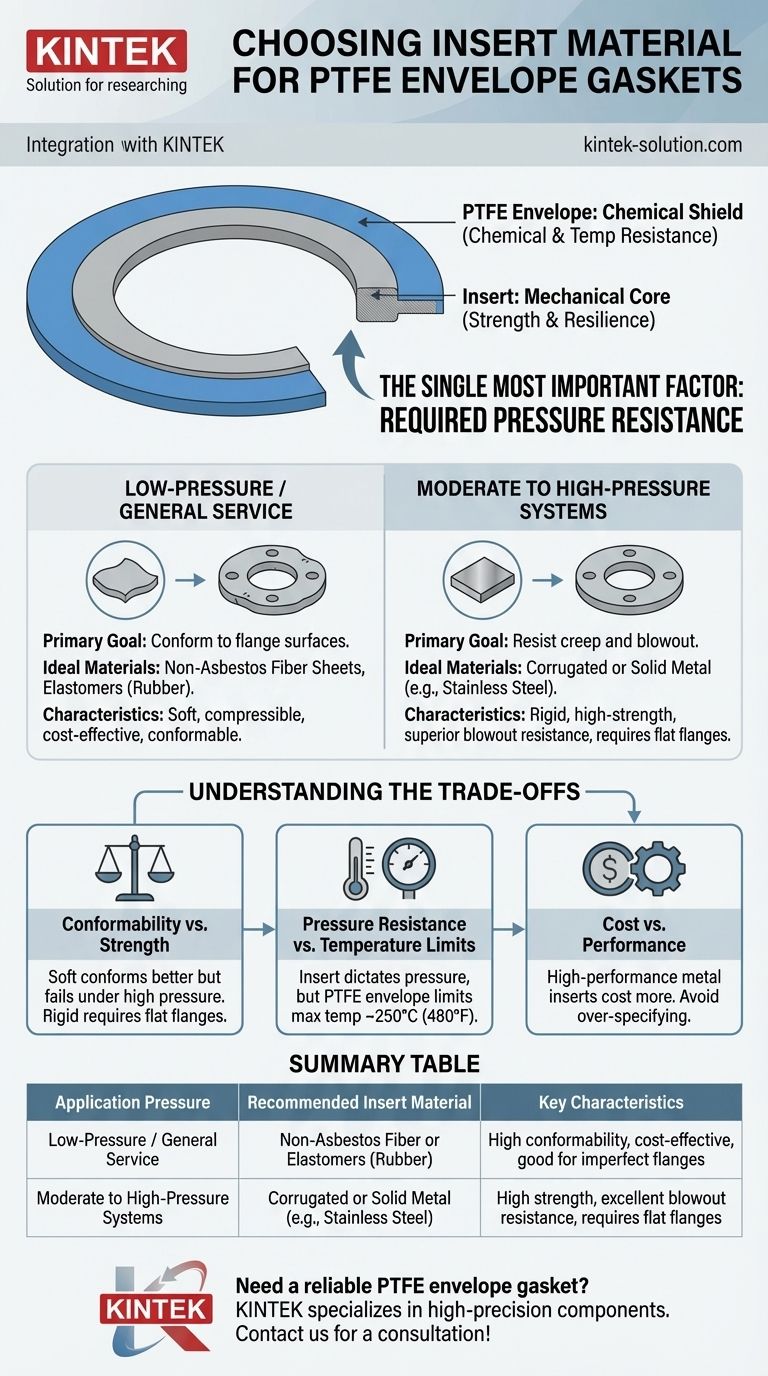

The single most important factor that determines the choice of insert material for a PTFE envelope gasket is the required pressure resistance for the application. The gasket is a two-part system: the outer PTFE "envelope" provides near-universal chemical resistance, while the inner "insert" material provides the mechanical strength and resilience needed to create and maintain a seal under load.

A PTFE envelope gasket separates its duties. The PTFE envelope handles the chemical and temperature challenges, so your choice of insert material is almost entirely a mechanical decision based on the pressure your system requires.

The Role of Each Component

To select the right insert, you must first understand that a PTFE envelope gasket is a composite seal. Each part has a distinct and complementary function.

The PTFE Envelope: The Chemical Shield

The outer envelope is made of Polytetrafluoroethylene (PTFE), a material renowned for its exceptional properties. This component is responsible for interfacing with the process media.

Its key contributions are high chemical resistance and a wide operating temperature range. Because PTFE is virtually inert, it can handle highly aggressive chemicals without degrading, preventing contamination of the process media.

The Insert: The Mechanical Core

The insert is the structural backbone of the gasket. It is completely protected from the process media by the PTFE envelope, so its chemical resistance is not a primary concern.

The insert's sole purpose is to provide the mechanical properties the soft PTFE lacks. This includes the compressive strength to withstand bolt loads and the resilience to resist creep and relaxation over the life of the seal, ensuring a consistent, leak-free joint.

Matching the Insert to Your Application's Demands

Since the insert provides the mechanical strength, your selection process should focus on the physical forces at play in your specific flange connection.

For Low-Pressure and General Service

In applications with low internal pressures, the primary goal is simply to conform to the flange surfaces to create an initial seal.

Softer, more compressible materials are ideal here. Common choices include non-asbestos fiber sheets or various types of elastomers (rubber). These materials are cost-effective and provide excellent adaptability to minor flange imperfections.

For Moderate to High-Pressure Systems

As system pressure increases, the risk of gasket creep and catastrophic blowout becomes a serious concern. The insert must be strong enough to resist these forces.

For these demanding applications, you must use a rigid, high-strength insert. The most common choices are corrugated or solid metal, often stainless steel, which provides superior load-bearing capacity and prevents the gasket from being extruded from the flange.

Understanding the Trade-offs

Selecting an insert material involves balancing competing priorities. Understanding these trade-offs is key to specifying a reliable and cost-effective seal.

Conformability vs. Strength

There is an inherent trade-off between an insert's ability to conform to surface irregularities and its ability to resist pressure.

A soft, conformable insert can easily seal slightly warped or scratched flanges but will fail under high pressure. A strong, rigid metal insert can withstand immense pressure but requires clean, flat, and parallel flange surfaces to seal effectively.

Pressure Resistance vs. Temperature Limits

While the insert material dictates the pressure rating, the entire gasket assembly is still limited by the temperature constraints of the PTFE envelope.

PTFE has a maximum continuous service temperature, typically around 250°C (480°F). Even if you use a high-temperature metal insert, the gasket's operational limit is defined by the PTFE envelope, its weakest link in terms of thermal resistance.

Cost vs. Performance

As expected, high-performance inserts designed for high pressures are more expensive. A corrugated stainless steel insert will carry a significant cost premium over a standard non-asbestos fiber insert. Over-specifying the insert for a simple, low-pressure application leads to unnecessary expense.

Making the Right Choice for Your Goal

To select the correct insert, focus on the primary mechanical demand of your application.

- If your primary focus is sealing aggressive media in a low-pressure system: A standard, soft insert like a non-asbestos or rubber sheet provides a cost-effective and reliable seal.

- If your primary focus is maintaining seal integrity in a high-pressure line: You must select a rigid insert, such as corrugated or solid metal, to provide the necessary blowout resistance.

- If your primary focus is sealing against imperfect or uneven flange surfaces: A more conformable, softer insert is preferable, but you must confirm the system pressure is well within its limited operational range.

By isolating the chemical and mechanical duties of the gasket, you can confidently select an insert that ensures a safe and reliable seal.

Summary Table:

| Application Pressure | Recommended Insert Material | Key Characteristics |

|---|---|---|

| Low-Pressure / General Service | Non-Asbestos Fiber or Elastomers (Rubber) | High conformability, cost-effective, good for imperfect flanges |

| Moderate to High-Pressure Systems | Corrugated or Solid Metal (e.g., Stainless Steel) | High strength, excellent blowout resistance, requires flat flanges |

Need a reliable PTFE envelope gasket for your specific pressure and chemical requirements?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including custom envelope gaskets with the ideal insert material for your application. Whether you're in the semiconductor, medical, laboratory, or industrial sector, we provide solutions from prototypes to high-volume orders.

Let our experts help you select the perfect gasket for superior sealing performance. Contact us today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems