In short, chemical inertness is crucial for PTFE coated fasteners because it creates a non-reactive barrier that shields the underlying metal from corrosive substances. This property ensures the fastener maintains its structural integrity and operational reliability in chemically aggressive environments where standard fasteners would quickly degrade and fail.

The core value of chemical inertness in PTFE coatings is not just surviving chemical exposure, but guaranteeing the fastener's physical and mechanical performance over its entire service life, preventing catastrophic failures and costly downtime.

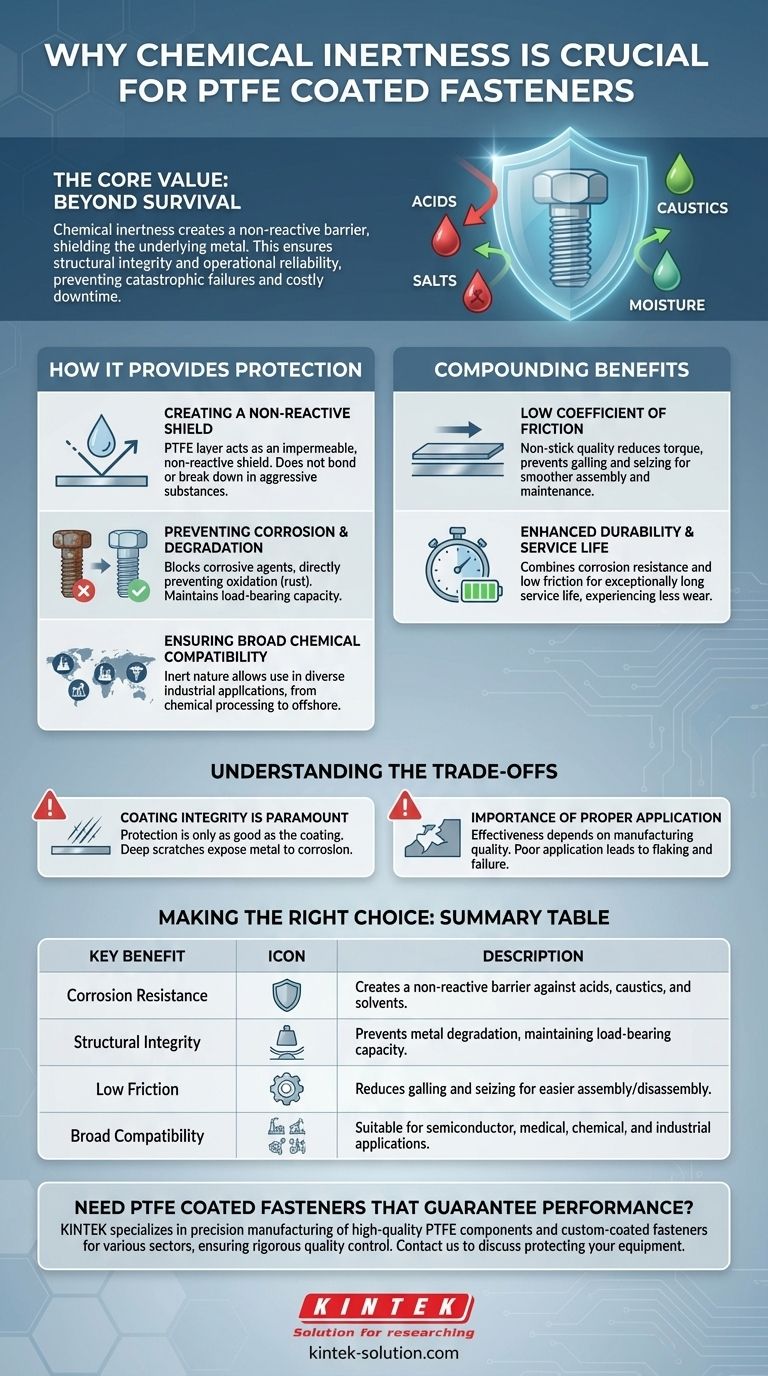

How Chemical Inertness Provides Protection

The primary function of a PTFE coating is to isolate the structural metal of the fastener from the surrounding environment. Its chemical inertness is the key property that makes this isolation effective.

Creating a Non-Reactive Shield

The PTFE layer acts as an impermeable shield. Because the coating is non-reactive, it does not bond with or break down when exposed to a wide range of aggressive substances, including acids, caustics, moisture, and salts.

This shield physically prevents corrosive agents from ever reaching the metal substrate of the fastener.

Preventing Corrosion and Degradation

By blocking contact with corrosive elements, the coating directly prevents chemical reactions like oxidation (rust). This is critical for maintaining the load-bearing capacity and structural integrity of the fastener.

An unprotected fastener can lose material to corrosion, weakening it to the point of failure. The PTFE coating eliminates this risk.

Ensuring Broad Chemical Compatibility

The inert nature of PTFE makes these fasteners suitable for an exceptionally wide array of industrial applications. From chemical processing plants to offshore oil and gas rigs, the fasteners can be specified with confidence that they will not react with the specific chemicals present in that environment.

The Compounding Benefits of a PTFE Coating

While chemical inertness is the foundation of its protective quality, it works in concert with other properties of PTFE to deliver a superior fastening solution for demanding jobs.

Low Coefficient of Friction

PTFE is famous for its "non-stick" quality, which translates to a very low coefficient of friction. This property significantly reduces the torque required to tighten fasteners, ensuring more accurate pre-load.

Crucially, it also prevents galling and seizing, where threads bind under pressure. This makes both assembly and, more importantly, disassembly for maintenance much smoother and less likely to damage equipment.

Enhanced Durability and Service Life

The combination of corrosion resistance and low friction results in an exceptionally long service life. The fastener is protected from environmental degradation while also experiencing less wear and tear during installation and removal cycles.

Understanding the Trade-offs

While highly effective, PTFE coated fasteners are a specialized solution. Their performance depends on understanding their limitations.

Coating Integrity is Paramount

The protection offered by the PTFE is only as good as the coating itself. If the coating is deeply scratched or chipped during installation or use, the exposed metal underneath becomes a potential point for corrosion to begin.

Proper handling and the use of correct installation tools are essential to maintain the integrity of the protective barrier.

The Importance of Proper Application

The effectiveness of the fastener is entirely dependent on the quality of the manufacturing process. A poorly applied or improperly cured coating will not adhere correctly to the substrate and can flake or peel away, rendering the chemical protection useless.

It is critical to source these components from reputable manufacturers who have stringent quality control over their coating processes.

Making the Right Choice for Your Application

Selecting the correct fastener is a critical engineering decision. A PTFE coated fastener is often the optimal choice when performance in harsh conditions is a priority.

- If your primary focus is survival in chemically aggressive environments: The chemical inertness of PTFE is non-negotiable to prevent corrosion and ensure long-term structural integrity.

- If your primary focus is routine maintenance and accessibility: The low-friction surface is a key advantage, preventing galling and allowing for predictable and non-destructive disassembly.

- If your primary focus is long-term reliability in exposed conditions: The combined benefits of corrosion resistance and durability make these fasteners a sound investment to avoid future failures and downtime.

Ultimately, choosing a PTFE coated fastener is a decision to prioritize operational certainty and safety in environments that punish lesser materials.

Summary Table:

| Key Benefit | Description |

|---|---|

| Corrosion Resistance | Creates a non-reactive barrier against acids, caustics, and solvents. |

| Structural Integrity | Prevents metal degradation, maintaining load-bearing capacity. |

| Low Friction | Reduces galling and seizing for easier assembly/disassembly. |

| Broad Compatibility | Suitable for semiconductor, medical, chemical, and industrial applications. |

Need PTFE coated fasteners that guarantee performance in your specific environment? KINTEK specializes in the precision manufacturing of high-quality PTFE components, including custom-coated fasteners for the semiconductor, medical, laboratory, and industrial sectors. We ensure coating integrity through rigorous quality control, from prototypes to high-volume orders. Contact us today to discuss how our chemically inert PTFE solutions can protect your equipment and prevent costly downtime.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs