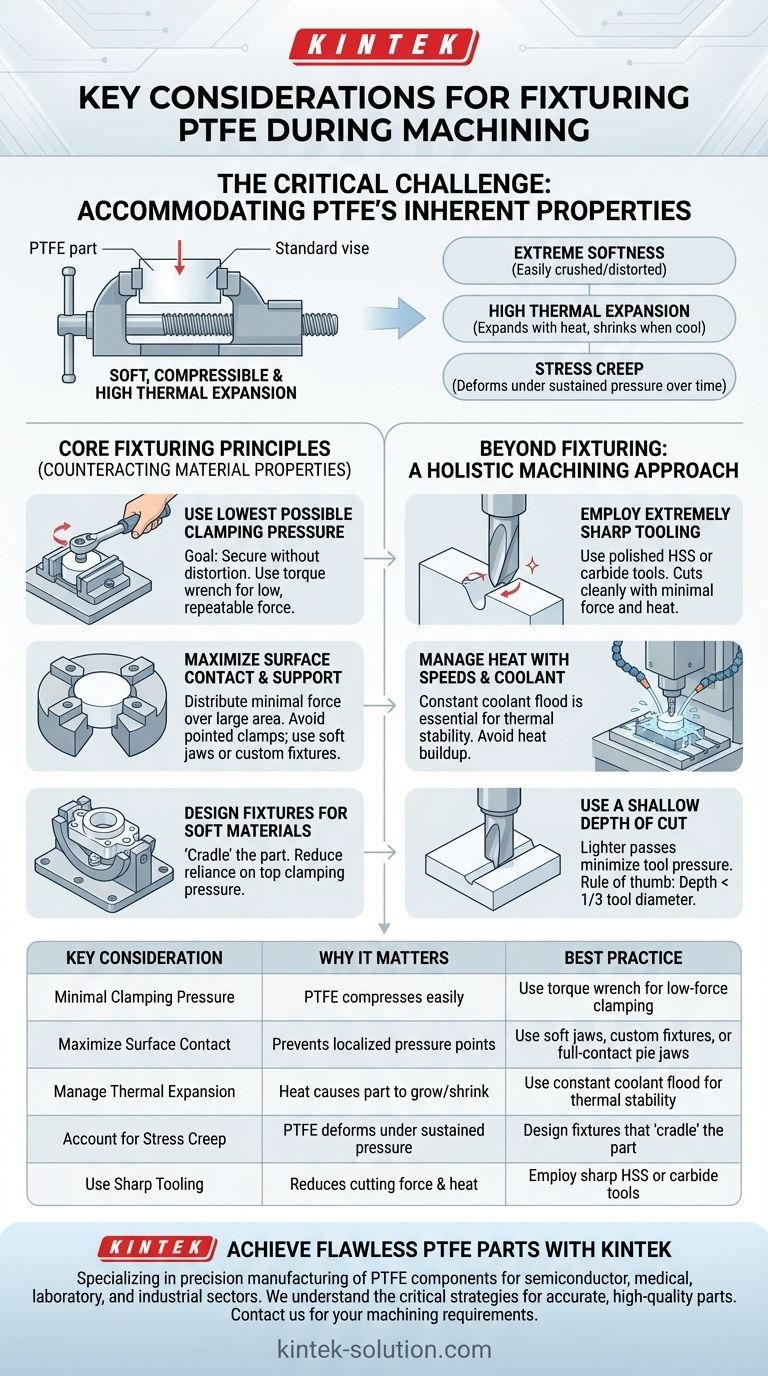

The most critical consideration for fixturing PTFE is to use minimal clamping pressure distributed over the largest possible surface area. Because PTFE is extremely soft, easily compressed, and has a high rate of thermal expansion, standard fixturing methods used for metals will deform the material, leading to dimensional inaccuracy.

The core challenge is not simply holding the PTFE, but accommodating its inherent properties. Effective fixturing is part of a larger strategy that manages the material's softness, tendency to expand with heat, and potential to "creep" under pressure.

The Unique Properties Dictating Your Fixturing Strategy

To fixture PTFE correctly, you must first understand the material you are working with. Its unique characteristics are the root cause of common machining failures.

Extreme Softness and Compression

PTFE is an incredibly soft material. Applying even moderate clamping force with a standard vise will easily crush or distort the workpiece, destroying any hope of holding tight tolerances.

High Coefficient of Thermal Expansion

PTFE expands and contracts significantly with temperature changes. The heat generated during machining will cause the part to grow, fight against the fixture, and then shrink as it cools, resulting in an undersized final part.

Stress Creep (Cold Flow)

Under sustained pressure, even if it's light, PTFE will slowly deform over time. This "creep" means a part that was secure at the beginning of a long machining cycle may become loose, or a clamped feature may be permanently indented.

Core Principles for Effective PTFE Fixturing

Your entire fixturing approach should be designed to counteract the material properties listed above.

Use the Lowest Possible Clamping Pressure

This is the single most important rule. The goal is to hold the part securely enough to resist cutting forces without causing any distortion. Using a torque wrench for repeatable, low-force clamping is highly recommended.

Maximize Surface Contact and Support

Never use pointed or small-surface-area clamps. Instead, use soft jaws, custom-machined fixtures, or full-contact pie jaws that distribute the minimal clamping force over a large area. This provides support and prevents localized pressure points.

Design Fixtures Specifically for Soft Materials

Whenever possible, create fixtures that "cradle" the part, providing support from below and the sides. This reduces the reliance on clamping pressure from above to secure the workpiece.

Beyond Fixturing: A Holistic Machining Approach

A perfect fixture will fail if the rest of your machining process generates excessive force or heat. The fixture is only one part of a system designed to gently handle PTFE.

Employ Extremely Sharp Tooling

Use sharp, polished cutting tools, preferably High-Speed Steel (HSS) or carbide designed for plastics. A sharp tool cuts cleanly with minimal force, reducing heat generation and the pressure exerted on the part and fixture.

Manage Heat with Speeds and Coolant

While PTFE can be cut at high speeds (200-1000 m/min), the primary goal is to avoid heat buildup. A constant flood of coolant is essential to wash away chips and keep the workpiece thermally stable, preventing the expansion that leads to inaccuracy.

Use a Shallow Depth of Cut

Deeper cuts increase tool pressure and heat. Take lighter passes to minimize the forces acting on the part. A good rule of thumb is a depth of cut no more than one-third of the tool's diameter.

Common Pitfalls to Avoid

Understanding what not to do is as important as knowing what to do. Many machinists new to PTFE make these fundamental errors.

Over-tightening a Standard Vise

This is the most common mistake. Treating PTFE like aluminum or steel will immediately result in a compressed, inaccurate part.

Ignoring Thermal Stability

Machining a part while it is warm and then measuring it after it has cooled to room temperature is a recipe for failure. The part will inevitably be undersized.

Using Worn or Incorrect Tooling

A dull tool doesn't cut; it pushes and rubs the material. This generates immense heat and pressure, overwhelming even the best fixturing strategy and leading to a poor surface finish.

Making the Right Choice for Your Goal

Your fixturing and machining strategy should align with your desired outcome.

- If your primary focus is achieving the tightest tolerances: Use custom-molded, full-contact fixtures, temperature-controlled coolant, and take light, precise finishing passes.

- If your primary focus is production speed: Design fixtures that allow for quick part changes but still provide broad support, and optimize cutting speeds to balance cycle time with minimal heat input.

- If your primary focus is general prototyping: Standard soft jaws on a vise with very light, repeatable clamping pressure are often sufficient for less critical dimensions.

Ultimately, successful PTFE machining comes from respecting the material's properties rather than fighting them.

Summary Table:

| Key Consideration | Why It Matters | Best Practice |

|---|---|---|

| Minimal Clamping Pressure | PTFE is extremely soft and compresses easily. | Use a torque wrench for repeatable, low-force clamping. |

| Maximize Surface Contact | Prevents localized pressure points and distortion. | Use soft jaws, custom fixtures, or full-contact pie jaws. |

| Manage Thermal Expansion | Heat from machining causes the part to grow and shrink. | Use a constant flood of coolant to maintain thermal stability. |

| Account for Stress Creep | PTFE deforms under sustained pressure over time. | Design fixtures that 'cradle' the part to reduce reliance on clamping. |

| Use Sharp Tooling | Reduces cutting force and heat generation. | Employ sharp HSS or carbide tools designed for plastics. |

Achieve Flawless PTFE Parts with KINTEK

Machining PTFE to precise specifications requires expert knowledge and specialized techniques to manage its unique properties. Don't let material challenges compromise your project.

KINTEK specializes in the precision manufacturing of PTFE components—from custom seals and liners to complex labware—for the semiconductor, medical, laboratory, and industrial sectors. We understand the critical fixturing and machining strategies needed to produce dimensionally accurate, high-quality PTFE parts, whether you need prototypes or high-volume production runs.

Let our expertise ensure your success. Contact KINTEK today to discuss your PTFE machining requirements and get a quote for your project.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- Why are custom Teflon rotary shaft seals preferred for demanding applications? Achieve Superior Reliability in Extreme Conditions

- How is the body portion of a PTFE seal element typically constructed? Securing Performance with Clamped Design

- What is the pH range for both PTFE and graphite packing? Selecting the Right Material for Extreme Conditions

- What are the electrical insulation properties of PTFE caps? Superior Dielectric Performance for Demanding Applications

- What types of products can be made from PTFE sheets in the chemical industry? | Gaskets, Liners & Seals

- Why are PTFE ball valves not recommended for slurries? Prevent Abrasive Damage and Valve Failure

- How do PTFE O-Rings perform under high heat conditions? Achieve Extreme Temperature Sealing

- How is PTFE rod applied in the food preparation industry? Unlock Safer, More Efficient Food Processing