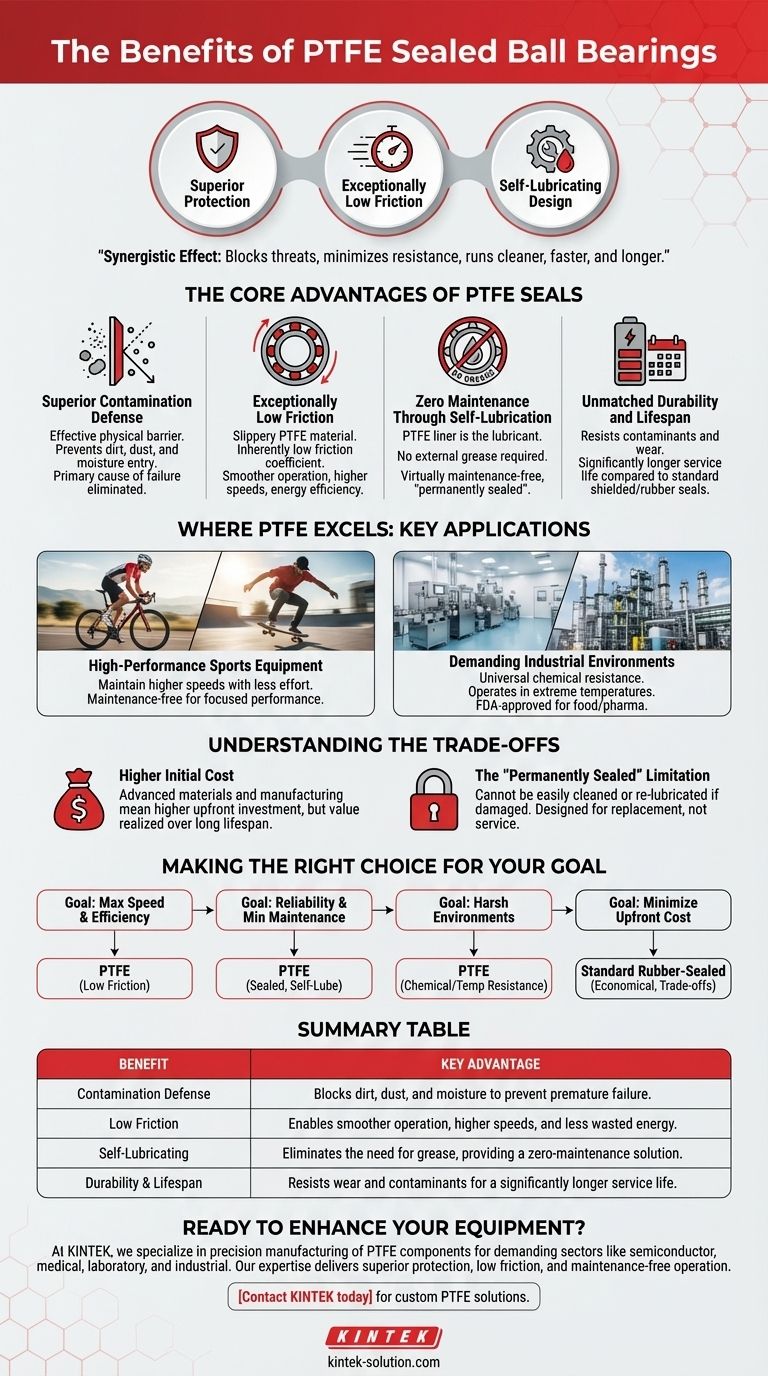

At their core, PTFE sealed ball bearings offer three primary benefits: superior protection against contamination, exceptionally low friction for higher efficiency, and a self-lubricating design that eliminates the need for maintenance. These attributes work together to create a bearing that is both faster and significantly more durable than many alternatives.

The true advantage of a PTFE sealed bearing is not just one feature, but how its material properties create a synergistic effect. It simultaneously blocks external threats like dirt and moisture while minimizing internal resistance, resulting in a component that runs cleaner, faster, and longer.

The Core Advantages of PTFE Seals Explained

To understand why PTFE sealed bearings are chosen for demanding applications, we need to look at the unique properties of Polytetrafluoroethylene (PTFE), the material often known by the brand name Teflon.

Superior Contamination Defense

The most immediate job of any bearing seal is protection. The PTFE seal forms a highly effective physical barrier.

This barrier prevents common contaminants like dirt, dust, and moisture from entering the bearing's internal raceway, which is the primary cause of premature bearing failure.

Exceptionally Low Friction

PTFE is one of the most slippery materials known. This translates directly to performance.

The material's inherently low coefficient of friction means there is less rotational resistance. This allows for smoother operation, higher attainable speeds, and less wasted energy.

Zero Maintenance Through Self-Lubrication

Unlike traditional bearings that rely on grease or oil, PTFE provides its own lubrication.

The PTFE liner or seal material itself is the lubricant, eliminating the need for external grease that can dry out or attract dirt. This is why they are often referred to as "permanently sealed" and are virtually maintenance-free.

Unmatched Durability and Lifespan

By solving the two biggest threats to a bearing's life—contamination and friction—PTFE seals directly contribute to longevity.

Because they resist both external contaminants and internal wear, these bearings have a significantly longer service life compared to standard shielded or rubber-sealed options under the right conditions.

Where PTFE Excels: Key Applications

The unique combination of protection, low friction, and durability makes these bearings a premium choice for specific uses where performance and reliability are critical.

High-Performance Sports Equipment

In applications like professional cycling or skateboarding, minimizing resistance is key.

PTFE sealed bearings help athletes maintain higher speeds with less effort. The sealed, maintenance-free design also means they can focus on performance without worrying about component failure.

Demanding Industrial Environments

The material properties of PTFE make it ideal for harsh conditions.

It offers universal resistance to most chemicals and can operate in extreme temperatures. Its suitability for food and pharmaceutical applications (often being FDA-approved) makes it a versatile choice for specialized machinery.

Understanding the Trade-offs

While highly effective, PTFE sealed bearings are not the universal solution for every situation. Objectivity requires acknowledging their limitations.

Higher Initial Cost

The advanced materials and manufacturing involved mean PTFE sealed bearings often come with a higher upfront cost than standard rubber-sealed or metal-shielded bearings. The value is realized over the component's longer, maintenance-free lifespan.

The "Permanently Sealed" Limitation

The greatest strength of the seal is also a potential drawback. If the bearing does somehow become contaminated or damaged, it cannot be easily cleaned or re-lubricated. It is designed for replacement, not for service.

Making the Right Choice for Your Goal

Selecting the correct bearing depends entirely on your primary objective.

- If your primary focus is maximum speed and efficiency: PTFE is the clear choice due to its exceptionally low friction properties.

- If your primary focus is reliability and minimal maintenance: The sealed, self-lubricating design is ideal for "set it and forget it" applications.

- If your primary focus is operation in harsh environments: PTFE's chemical and temperature resistance makes it superior for industrial or challenging conditions.

- If your primary focus is minimizing upfront cost: A standard rubber-sealed bearing may be a more economical initial purchase, though with a trade-off in performance and maintenance.

Ultimately, choosing the right bearing is about aligning the unique strengths of the material with your specific performance demands.

Summary Table:

| Benefit | Key Advantage |

|---|---|

| Contamination Defense | Blocks dirt, dust, and moisture to prevent premature failure. |

| Low Friction | Enables smoother operation, higher speeds, and less wasted energy. |

| Self-Lubricating | Eliminates the need for grease, providing a zero-maintenance solution. |

| Durability & Lifespan | Resists wear and contaminants for a significantly longer service life. |

Ready to enhance your equipment's performance and reliability?

At KINTEK, we specialize in precision manufacturing of PTFE components, including seals and custom parts for demanding applications in the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures you get components that deliver the superior protection, low friction, and maintenance-free operation detailed in this article.

Whether you need a prototype or a high-volume order, we are committed to delivering the quality and precision your projects require.

Contact KINTEK today to discuss how our PTFE solutions can meet your specific needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs