In the electronics industry, Teflon (PTFE) sheets are primarily used for high-performance electrical insulation, critical circuit board components, and low-friction surfaces. Their value stems from a unique combination of properties that ensures reliability in high-voltage, high-frequency, and chemically aggressive environments where standard materials would fail.

While prized for its exceptional electrical insulation, the true value of Teflon in electronics lies in its unique combination of thermal stability, chemical inertness, and low friction. This makes it a critical material for components that must perform reliably under extreme conditions.

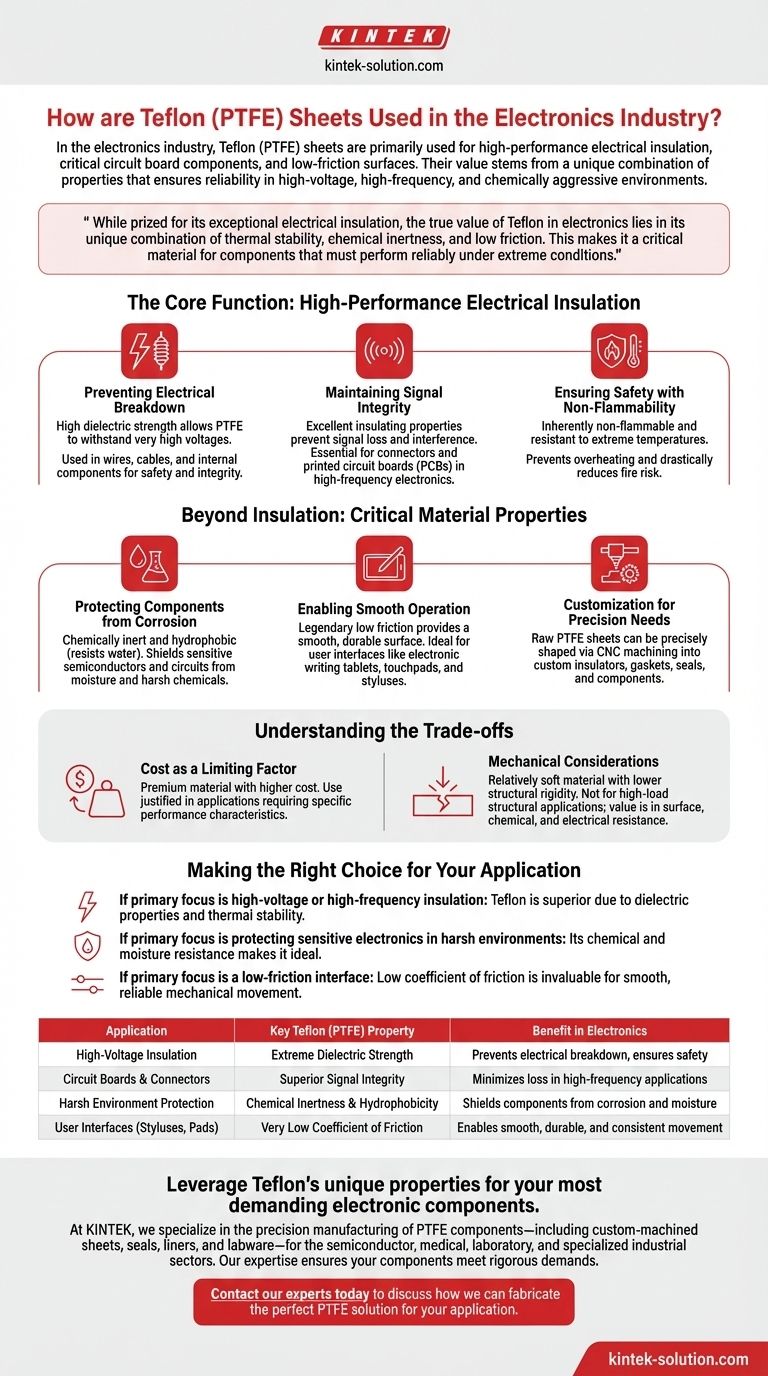

The Core Function: High-Performance Electrical Insulation

Teflon's primary role in electronics is to prevent the unwanted flow of electricity. Its molecular structure makes it one of the best-known insulators, a property essential for modern electronics.

Preventing Electrical Breakdown

PTFE has an extremely high dielectric strength, meaning it can withstand very high voltages without breaking down and allowing current to pass through.

This makes it indispensable for insulating wires, cables, and internal components in high-voltage equipment, ensuring both safety and operational integrity.

Maintaining Signal Integrity

In high-frequency electronics, such as radio and microwave circuits, maintaining a clean signal is paramount.

Teflon's excellent insulating properties prevent signal loss and interference, making it a preferred material for connectors and printed circuit boards (PCBs) used in telecommunications and data processing.

Ensuring Safety with Non-Flammability

Electronic components generate heat, and managing this thermal load is a key design challenge.

Teflon is inherently non-flammable and resistant to extreme temperatures. This quality helps prevent components from overheating and drastically reduces the risk of fire.

Beyond Insulation: Critical Material Properties

While its electrical properties are its most famous trait, Teflon's utility is magnified by other key characteristics that solve different engineering problems.

Protecting Components from Corrosion

Modern electronics are often deployed in harsh environments where they may be exposed to moisture or chemicals.

Teflon is almost completely chemically inert and hydrophobic (resists water). This allows it to act as a protective barrier, shielding sensitive semiconductors and circuits from corrosion and moisture damage.

Enabling Smooth Operation

The low friction of Teflon is legendary, and this property is leveraged in user-interface components.

It provides a smooth, durable surface for products like electronic writing tablets, touchpads, and styluses, where consistent and effortless movement is required.

Customization for Precision Needs

Raw PTFE sheets are not the final product. They serve as a base material that can be precisely shaped.

Through processes like CNC machining, Teflon can be fabricated into custom insulators, gaskets, seals, and other components that meet the exact specifications of a device.

Understanding the Trade-offs

No material is perfect for every situation. To use Teflon effectively, it's crucial to understand its limitations.

Cost as a Limiting Factor

Teflon is a premium performance material, and its cost is significantly higher than that of common plastics like polyethylene or PVC.

Its use is therefore justified primarily in applications where its specific performance characteristics are a non-negotiable requirement.

Mechanical Considerations

While durable and wear-resistant, PTFE is a relatively soft material with lower structural rigidity compared to engineering plastics like PEEK or nylon.

It is not typically used for high-load, structural applications. Its value is in its surface properties and its chemical and electrical resistance, not its tensile strength.

Making the Right Choice for Your Application

Selecting the right material requires aligning its properties with your primary design goal.

- If your primary focus is high-voltage or high-frequency insulation: Teflon is the superior choice due to its excellent dielectric properties and thermal stability.

- If your primary focus is protecting sensitive electronics in harsh environments: Its unparalleled chemical and moisture resistance makes it ideal for shielding components from corrosive elements.

- If your primary focus is a low-friction interface or moving part: Its uniquely low coefficient of friction is invaluable for devices requiring smooth, reliable mechanical movement.

Understanding these distinct properties allows you to leverage Teflon not just as an insulator, but as a strategic solution for your most demanding electronic designs.

Summary Table:

| Application | Key Teflon (PTFE) Property | Benefit in Electronics |

|---|---|---|

| High-Voltage Insulation | Extreme Dielectric Strength | Prevents electrical breakdown, ensures safety |

| Circuit Boards & Connectors | Superior Signal Integrity | Minimizes loss in high-frequency applications |

| Harsh Environment Protection | Chemical Inertness & Hydrophobicity | Shields components from corrosion and moisture |

| User Interfaces (Styluses, Pads) | Very Low Coefficient of Friction | Enables smooth, durable, and consistent movement |

Leverage Teflon's unique properties for your most demanding electronic components.

At KINTEK, we specialize in the precision manufacturing of PTFE components—including custom-machined sheets, seals, liners, and labware—for the semiconductor, medical, laboratory, and specialized industrial sectors. Whether you need prototypes or high-volume orders, our expertise ensures your components meet the rigorous demands for insulation, chemical resistance, and reliability.

Contact our experts today to discuss how we can fabricate the perfect PTFE solution for your application.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What is the significance of low surface adhesion in PTFE diaphragm valves for pharmaceutical research? Ensure Sample Integrity and Process Reliability

- In which industries are Teflon (PTFE) balls commonly used? Key Applications & Benefits

- What is Teflon gland packing and why is it important? Ensure Leak-Free Sealing in Harsh Conditions

- How might nanotechnology improve PTFE seal performance? Achieve Unmatched Durability and Efficiency

- How does the low friction coefficient of PTFE coatings affect tightening torque? Achieve Accurate Clamping Force Safely

- What considerations should be made when deciding to use PTFE gaskets? Balance Chemical Resistance with Mechanical Limits

- How are Teflon-encapsulated O-Rings utilized in heavy equipment and hydraulics? Achieve Superior Sealing and Reduce Downtime

- How is a PTFE bearing pad installed on prefabricated beams? A Guide to Secure, Low-Friction Installation