In short, nanotechnology enhances PTFE seals by fundamentally upgrading the material at a molecular level. This results in significant improvements, including a lower coefficient of friction, superior chemical resistance, and a dramatic increase in durability and service life.

The core takeaway is that nanotechnology transforms PTFE from a standard passive component into a highly engineered, customizable material. This allows for the creation of seals that are not only more durable but also smarter and more sustainable, capable of performing in the most demanding applications.

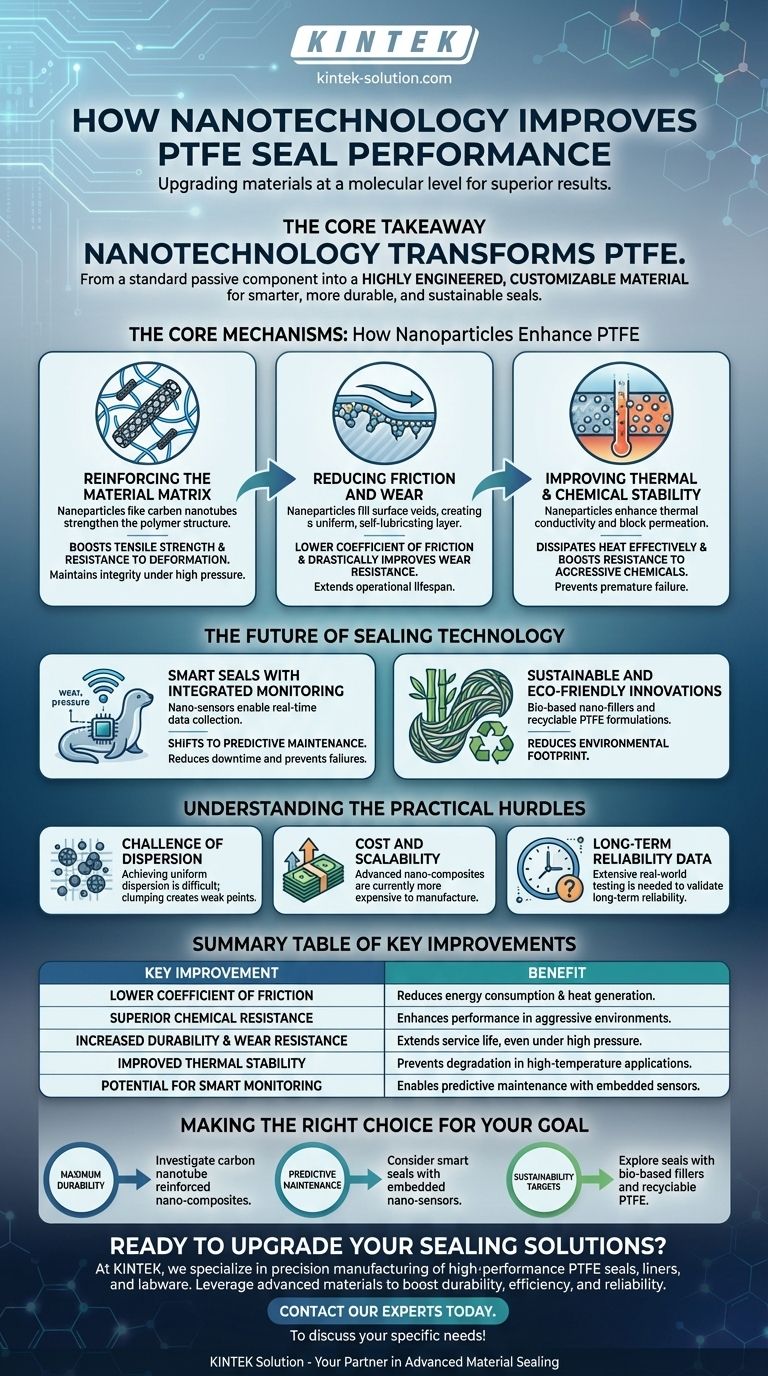

The Core Mechanisms: How Nanoparticles Enhance PTFE

The value of nanotechnology in PTFE seals comes from the unique properties that emerge when materials are engineered at the nanoscale. These are not simple mixtures; they are true composite materials with fundamentally different characteristics.

Reinforcing the Material Matrix

Nanoparticles, such as carbon nanotubes or nanoclays, act as a microscopic reinforcement within the polymer structure. This is analogous to how rebar strengthens concrete.

This reinforcement significantly boosts the material's tensile strength and resistance to deformation under load. The result is a seal that maintains its integrity for longer, especially in high-pressure systems.

Reducing Friction and Wear

At a microscopic level, even a smooth PTFE surface has imperfections. Nanoparticles can fill these voids and create a more uniform, self-lubricating surface.

This leads to a lower coefficient of friction, reducing the energy required for movement and minimizing heat generation. More importantly, it drastically improves the seal's wear resistance, extending its operational lifespan.

Improving Thermal and Chemical Stability

The addition of certain nanoparticles can enhance the thermal conductivity of the PTFE, allowing it to dissipate heat more effectively. This prevents degradation in high-temperature applications.

Furthermore, by filling the porous gaps in the PTFE matrix, nanoparticles make the material less permeable. This boosts its resistance to aggressive chemicals and gases, preventing premature failure.

The Future of Sealing Technology

The integration of nanotechnology is a gateway to even more advanced concepts that are currently in development. These innovations move beyond simple performance gains and into new functional capabilities.

Smart Seals with Integrated Monitoring

One of the most promising trends is the development of smart seals. By embedding nano-sensors directly into the PTFE composite, it becomes possible to monitor wear, pressure, and temperature in real-time.

This capability shifts maintenance from a reactive or scheduled process to a predictive one, reducing downtime and preventing catastrophic failures.

Sustainable and Eco-Friendly Innovations

Nanotechnology also opens doors to more environmentally responsible materials. Research is underway on using bio-based nano-fillers, such as bamboo fibers, to create high-performance seals.

Combined with efforts to develop recyclable PTFE formulations, this could significantly reduce the environmental footprint of sealing components.

Understanding the Practical Hurdles

While the potential is enormous, the widespread adoption of nano-enhanced PTFE faces real-world challenges. Objectivity requires acknowledging these limitations.

The Challenge of Dispersion

Achieving a uniform dispersion of nanoparticles throughout the PTFE matrix is technically difficult. If the particles clump together, they can create weak points in the material rather than reinforcing it.

Cost and Scalability

Advanced nano-composites are currently more expensive and complex to manufacture than traditional PTFE. This higher cost is a significant barrier to adoption, particularly for applications that are not performance-critical.

Long-Term Reliability Data

As with any new material technology, nano-enhanced seals require extensive real-world testing to validate their long-term reliability across a wide range of operational conditions. Building this body of evidence takes time.

Making the Right Choice for Your Goal

As this technology matures, selecting the right approach will depend entirely on your primary engineering objective.

- If your primary focus is maximum durability in extreme environments: You should investigate nano-composites, particularly those reinforced with carbon nanotubes, for their superior wear resistance and strength.

- If your primary focus is predictive maintenance and system uptime: The emerging field of smart seals with embedded nano-sensors offers the most significant long-term value.

- If your primary focus is meeting sustainability targets: Keep an eye on the development of seals using bio-based fillers and recyclable PTFE formulations.

Ultimately, nanotechnology is elevating the humble seal from a simple component to a critical, high-performance system element.

Summary Table:

| Key Improvement | Benefit |

|---|---|

| Lower Coefficient of Friction | Reduces energy consumption and heat generation. |

| Superior Chemical Resistance | Enhances performance in aggressive environments. |

| Increased Durability & Wear Resistance | Extends service life, even under high pressure. |

| Improved Thermal Stability | Prevents degradation in high-temperature applications. |

| Potential for Smart Monitoring | Enables predictive maintenance with embedded sensors. |

Ready to upgrade your sealing solutions with high-performance PTFE components?

At KINTEK, we specialize in precision manufacturing of PTFE seals, liners, and labware. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get components engineered for superior performance in semiconductor, medical, laboratory, and industrial applications.

Let us help you leverage advanced materials like nano-enhanced PTFE to boost durability, efficiency, and reliability in your systems. Contact our experts today to discuss your specific needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What special requirements do aerospace applications have for PTFE O-ring seals? Ensuring Reliability in Extreme Environments

- What are the limitations of PTFE sheet lining in chemical tanks? Understand the Critical Trade-Offs

- What are the main advantages of PTFE mechanical seals? Superior Chemical & Temperature Resistance

- In what types of medical devices are PTFE liners particularly useful? Enhance Minimally Invasive Procedures with Superior Lubricity

- What are the disadvantages of solid Teflon O-rings? Key Limitations for Reliable Sealing

- What type of thermoplastic is Teflon and what are its inherent properties? | A Guide to PTFE's Unique Strengths

- What are some physical properties of PTFE with fillers? Enhance Strength, Wear, and Thermal Performance

- What is the temperature range that PTFE bushings can endure? Operate from -200°C to +260°C