In the demanding world of heavy equipment, Teflon-encapsulated O-rings serve a critical function by providing a robust sealing solution for hydraulic fittings, valves, and cylinders. They are engineered to withstand the extreme pressure, friction, and aggressive chemical environments that cause standard elastomer seals to fail, ultimately reducing maintenance needs and costly downtime.

The core challenge in heavy hydraulics is that a seal must be both flexible enough to conform to surfaces and tough enough to resist wear and chemical attack. A Teflon-encapsulated O-ring solves this by combining a resilient elastomer core with a durable, low-friction Teflon jacket, offering the best of both worlds.

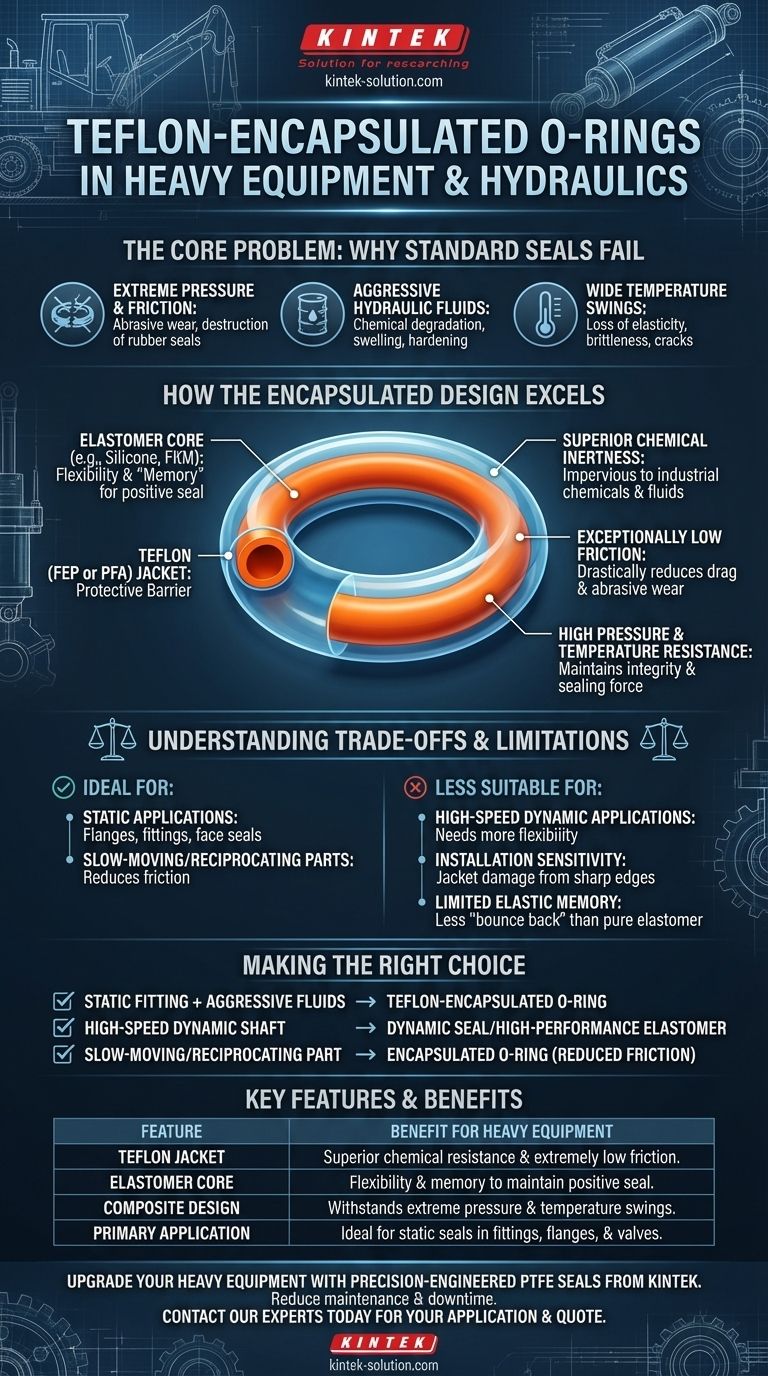

The Core Problem: Why Standard Seals Fail

Standard O-rings made from a single elastomer material often struggle to survive the harsh operating conditions found in heavy machinery and hydraulic systems.

Extreme Pressure and Friction

Hydraulic systems operate under immense pressure. This force, combined with the movement of components like pistons and valve spools, creates significant friction and abrasive wear that can quickly destroy a conventional rubber seal.

Aggressive Hydraulic Fluids

Many hydraulic fluids contain additives and chemicals that are corrosive to standard elastomers. Over time, these fluids can cause a seal to swell, harden, or chemically degrade, leading to leaks and system failure.

Wide Temperature Swings

The operational cycle of heavy equipment generates significant heat. These temperature fluctuations can cause standard seals to lose their elasticity and become brittle, leading to cracks and a loss of sealing force.

How the Encapsulated Design Excels

A Teflon-encapsulated O-ring is a composite seal, intelligently designed to overcome the weaknesses of a single-material part.

The Two-Part Structure

The design consists of two key elements: an inner core and an outer jacket. The elastomer core (typically Silicone or FKM) provides the flexibility and "memory" needed to create and maintain a positive seal.

The Protective Teflon Jacket

A seamless Teflon (FEP or PFA) jacket encapsulates the core. This outer shell is the component in contact with the system, providing a protective barrier with unique properties.

Superior Chemical Inertness

The Teflon jacket is virtually impervious to all industrial chemicals, including aggressive hydraulic fluids. This prevents the chemical degradation that plagues many standard seals.

Exceptionally Low Friction

Teflon is renowned for its incredibly low coefficient of friction. This property drastically reduces drag and abrasive wear in hydraulic components, extending the life of both the seal and the machinery itself.

High Pressure and Temperature Resistance

The combination of a stable core and a durable jacket allows the O-ring to maintain its integrity and sealing force under the high pressures and extreme temperatures common in hydraulic systems.

Understanding the Trade-offs and Limitations

While highly effective, Teflon-encapsulated O-rings are not a universal solution. Understanding their limitations is key to using them correctly.

Primarily for Static Applications

These O-rings are at their best when used as static seals, such as in flanges, fittings, or face seals. Their relative stiffness makes them less suitable for high-speed, dynamic applications where a more flexible seal is required.

Installation Sensitivity

The Teflon jacket is less forgiving than a solid elastomer. It can be scratched or damaged if installed improperly over sharp threads or edges, which can compromise the seal's integrity from the start.

Limited Elastic Memory

The Teflon shell does not "bounce back" from compression as readily as a pure elastomer. In applications with large clearance gaps or significant hardware movement, a high-performance solid elastomer may provide a more reliable long-term seal.

Making the Right Choice for Your Application

Selecting the correct seal requires matching its strengths to your specific operational demands.

- If your primary focus is sealing a static hydraulic fitting with aggressive fluids: A Teflon-encapsulated O-ring is an ideal choice for its unmatched chemical resistance and long-term reliability.

- If your primary focus is a high-speed, dynamic application like a rapidly rotating shaft: You should evaluate a specialized dynamic seal or a high-performance elastomer designed specifically for wear resistance and flexibility.

- If you are trying to reduce friction in a slow-moving or reciprocating part: The low-friction surface of an encapsulated O-ring can significantly extend the service life of both the seal and its mating hardware.

By leveraging this unique combination of material properties, you can engineer hydraulic systems with greater durability, efficiency, and significantly reduced downtime.

Summary Table:

| Key Feature | Benefit for Heavy Equipment & Hydraulics |

|---|---|

| Teflon (FEP/PFA) Jacket | Superior chemical resistance and extremely low friction. |

| Elastomer Core (e.g., Silicone, FKM) | Provides flexibility and memory to maintain a positive seal. |

| Composite Design | Withstands extreme pressure and temperature swings. |

| Primary Application | Ideal for static seals in fittings, flanges, and valves. |

Upgrade your heavy equipment with precision-engineered PTFE seals from KINTEK.

Our Teflon-encapsulated O-rings are manufactured to the highest standards of precision, offering the durability and chemical resistance your hydraulic systems demand. Whether you need a custom prototype or a high-volume order for the semiconductor, medical, laboratory, or industrial sectors, KINTEK delivers reliable sealing solutions that reduce maintenance and prevent costly downtime.

Contact our experts today to discuss your specific application and request a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials